10 FAQs About Wire Binding

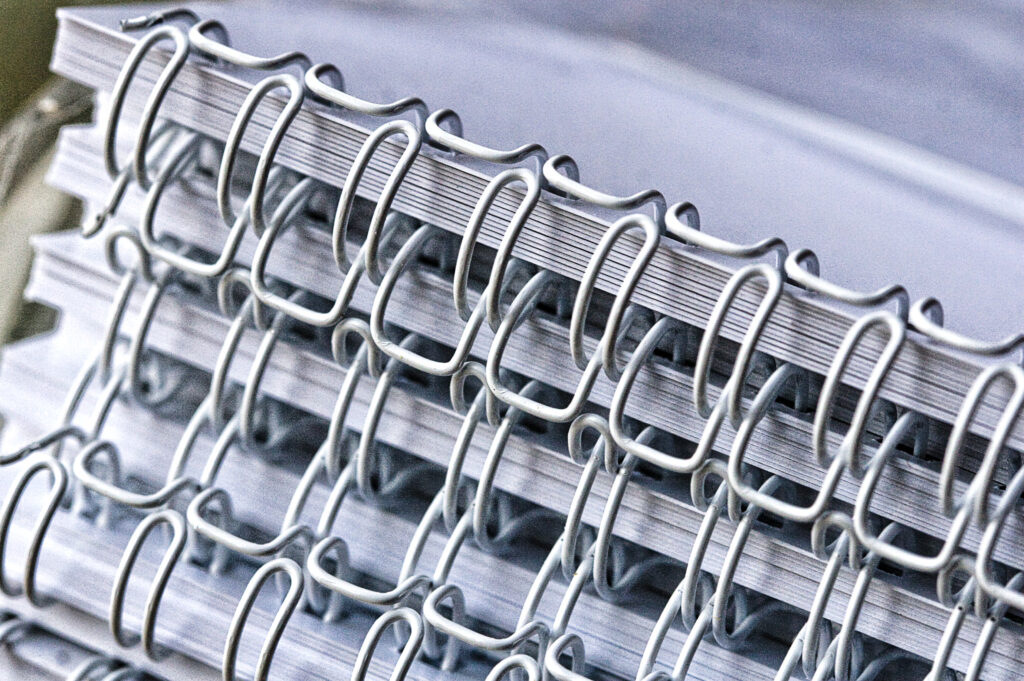

Wire binding, also known as twin-loop binding or double-loop binding, is a popular method of document binding that uses a metal wire or coil to secure the pages together. This binding technique is commonly used for creating professional-looking presentations, reports, notebooks, and other documents.

The process involves punching evenly spaced rectangular holes along the edge of the document and then threading a wire or coil through these holes. The wire is usually made of metal, such as steel or aluminum, and is available in various colours and sizes to accommodate different document thicknesses. Once the wire is threaded through the punched holes, it is then closed using a wire closer, creating a secure and durable bind.

Wire binding provides a sleek and modern appearance to documents, and the bound pages can lay flat when opened, allowing for easy reading and note-taking. It is a popular choice for businesses, educational institutions, and individuals who require a professional and functional document presentation.

Most FAQs When It Comes to Wire Binding

1. What types of documents are suitable for wire binding?

Wire binding is suitable for various documents, including:

- Financial and business reports

- Professional presentations

- Notebooks and journals

- Marketing materials

- Wall and Desk Calendars

- Notepads, and more!

It provides a sleek and modern appearance, making it a popular choice for professional and functional document presentations.

2. Can wire-bound documents lay flat when opened?

Yes, one of the advantages of wire binding is that documents can lay flat when opened. This feature allows for easy reading, note-taking, and a professional presentation.

3. Is wire binding suitable for high-volume document production?

Wire binding is suitable for moderate to high-volume document production. However, for extremely high volumes, other binding methods like coil binding or perfect binding might be more efficient.

4. Can pages be added or removed from a wire-bound document?

Answer: Adding or removing pages from a wire-bound document is possible but can be a bit more involved compared to some other binding methods. Specialized equipment may be required to reopen and close the wire.

5. Is wire binding suitable for documents with heavy covers?

Wire binding can accommodate heavy covers, providing a sturdy and professional finish. However, the thickness of the covers may affect the overall binding capacity of the document.

6. Is wire binding a cost-effective binding method?

Wire binding is generally a cost-effective binding method, especially for moderate-volume binding needs. The upfront costs for equipment and supplies are reasonable, making it accessible for businesses and individuals alike.

7. Are there different hole patterns for wire binding?

Yes. It is referred to as wire bind pitch. There are different hole patterns available for wire binding, including 3:1 pitch (three holes per inch) and 2:1 pitch (two holes per inch). The choice depends on the specific wire binding machine and the desired document presentation. You will need to be sure your wire binding machine has the same hole pattern as the wire spines you get because a 2:1 punch machine will only work with a 2:1 binding wire.

8. What sizes and colours are available for wire binding coils?

Wire binding coils come in various sizes and colours to accommodate different document thicknesses and aesthetic preferences. Common sizes include 1/4 inch, 3/8 inch, 1/2 inch, and up to 1 inch or more. Colours range from standard metallic shades to custom options. Also, 2:1 wires feature 21 loops and 3:1 wires feature 32 loops.

9. How long are binding wires?

Binding wires are either pre-cut to 11″ lengths for standard letter-size paper, or continuous and wrapped around a spool.

10. What do I need to Bind with Wire-O?

- Wire-O Binding Machine: A Wire-O binding machine is specifically designed for punching holes along the edge of your documents and threading the wire through those holes. These machines come in various models, from manual to electric, with different punching capacities. This will need to be in the same pitch as the wire sizes you plan to bind with. Some machines out there will do both 3:1 and 2:1 pitch wires, but the majority of them will do one or the other.

- Wire Closer: A wire closer is necessary to close the wire once it’s threaded through the punched holes. Some Wire-O binding machines have a built-in wire closer, while others may require a separate unit. Wire closers usually have a wire hanger that you send your spine on to easily place the pages of your book. You then would take the book and wire off the hanger, place it into the closer, and either pull a handle or press a button (if electric) to close the wire around your pages.

Are you a business owner seeking to enhance your document organization and presentation capabilities? Consider the efficiency and professionalism that wire binding machines can bring to your operations. Contact us today to explore a range of comb binding solutions tailored to your specific needs, and elevate the way you present documents in your business.