6 Most Common Types of Binding Methods

When it comes to information sharing and document presentation, the choice of a binding method serves as the architectural backbone for how we organize and convey our ideas. From scholarly dissertations to corporate reports, creative portfolios, and important legal documents, the binding method employed plays a crucial role in shaping the professionalism, durability, and accessibility of these materials. This article is dedicated to unravelling the diverse landscape of binding techniques, shedding light on the most common methods used across various sectors, including academia, businesses, design, and publishing. By understanding these binding options and their unique advantages, readers from all walks of life can make informed decisions on how best to encapsulate their ideas and make a lasting impact through the presentation of their documents.

Why is Binding Important?

The choice of a binding method isn’t just a technical detail; it’s a decision that directly impacts the user experience and the longevity of the materials. Whether you’re a student preparing a thesis, a marketing professional compiling a client presentation, an artist binding a portfolio, or a legal expert organizing contracts, your choice of binding method can make the difference between a document that leaves a memorable impression and one that falls apart, literally or figuratively. By examining the most common types of binding methods and understanding their applications, readers across various sectors will gain valuable insights into elevating the quality and professionalism of their printed materials, ensuring that their ideas are well-presented and effectively preserved for future reference.

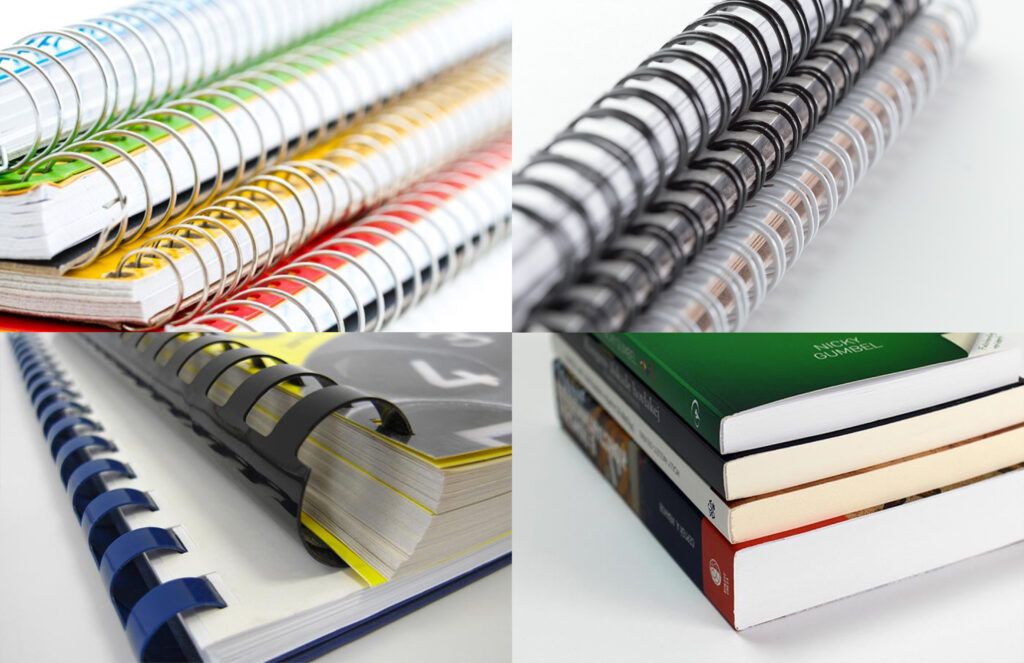

Most Common Types of Binding Methods

Coil/Spiral Binding

Coil or spiral binding is a popular document binding method that involves using a continuous plastic or metal coil, often in the shape of a spiral, to hold the pages of a document together. This binding technique is characterized by small, evenly spaced holes punched along the edge of the document’s pages, and the coil is threaded through these holes. Once the coil is in place, it is usually crimped or twisted at the ends to prevent it from unravelling.

Pros:

- Documents can lay completely flat, making them easy to read and allowing for effortless note-taking or photocopying.

- Can be opened and rotated a full 360 degrees.

- Resilient and can withstand heavy use. The plastic or metal coil is less prone to bending or breaking.

- It’s relatively simple to add or remove pages from coil-bound documents.

Cons:

- While it’s easy to add or remove pages, making edits to existing pages in a coil-bound document can be challenging without disassembling and rebinding the entire document.

- The front and back covers on coil-bound documents are not as secure as with some other binding methods, and they may be prone to bending or tearing over time.

- May not be suitable for very thick documents.

Binding Machine Required: Coil Binding Machines

Comb/Cerlox Binding

Comb binding, also known as Cerlox binding, is a popular document binding method that uses a plastic comb spine with multiple, evenly spaced, rectangular-shaped teeth to hold the pages of a document together. The comb spine is inserted through rectangular holes punched along the edge of the document’s pages. Once in place, the comb is opened, and the pages are threaded onto the teeth of the comb. Afterward, the comb is closed, securing the pages in place.

The result is a neatly bound document that allows for easy page-turning and lays flat when opened. Comb binding is commonly used for various applications, including reports, presentations, manuals, and school projects.

Pros:

- Flexibility in editing. Pages can be easily added, removed, or reordered without the need to disassemble the entire document.

- Documents can lay flat when opened, providing a user-friendly reading and note-taking experience.

- Plastic comb spines are robust and durable.

- Comb bindings come in various colours and sizes, allowing for personalization and enhancing the visual appeal of documents.

- Can accommodate a relatively high page count, suitable for documents of varying thicknesses.

Cons:

- While comb-bound documents lay flat, they don’t allow for a full 360-degree page rotation like coil-bound documents.

- The plastic comb spines may be susceptible to breakage if subjected to rough handling or excessive bending.

Binding Machine Required: Comb Binding Machines

Wire Binding / Wire-O Binding

Wire binding, often referred to as Wire-O binding, is a document binding method that uses a twin-loop wire spine to hold the pages of a document together. This binding method is characterized by evenly spaced double-loop wires that run along the edge of the document’s pages. The pages have small, round holes punched near the edge, and the wire spine is threaded through these holes. Once in place, the wire spine is crimped at both ends to secure the pages.

The result is a neatly bound document that allows for easy page-turning and lays flat when opened. Wire binding is commonly used for various applications, including calendars, notebooks, presentations, and reports.

Pros:

- Provides a sleek and professional look.

- Can be opened and laid flat.

- The twin-loop wire spines are robust and resistant to bending.

- Allows a full 360-degree page rotation, offering exceptional flexibility for referencing specific pages.

Cons:

- Making edits to existing pages in wire-bound documents can be challenging without disassembling and rebinding the entire document.

- Wire spines may be susceptible to scratching, which can impact the overall appearance of the bound document.

Binding Machine Required: Wire Binding Machines

Saddle Stitching

Saddle stitching is a common and cost-effective bookbinding method used to bind booklets, brochures, magazines, and other multi-page publications. The term “saddle stitching” refers to folding a stack of pages in half, creating a crease or fold along the spine. These folded pages are then placed on a saddle-like apparatus, which aligns the folded edges. A length of wire, thread, or staple is driven through the fold (spine) of the pages, securing them together. Saddle stitching is characterized by the staple or stitch along the booklet’s spine, resulting in a simple and functional binding that is especially suitable for publications with a lower page count, typically up to 64 pages.

Pros:

- Cost-effective binding method, making it suitable for large print runs.

- Relatively fast production, allowing for efficient production of publications.

- Lays relatively flat when opened.

- Compact and easy to store.

- Requires fewer materials compared to some other binding methods.

Cons:

- Only suitable for documents with a lower page count.

- May not be as durable as those bound with other methods.

- Not Suitable for Thick Paper Stocks.

- Does not allow for custom printing or labelling on the spine of the publication.

Binding Machine Required: Wire Stitchers and Staplers

Perfect Binding/Soft Cover Binding

Perfect binding, also known as soft cover binding, is a popular bookbinding method used to create paperback books, catalogues, magazines, and other publications with a flat spine. It is characterized by the use of adhesive to bind the pages together.

Pros:

- Provides a polished and professional appearance.

- The flat spine allows for clear printing of titles and information.

- Can accommodate larger page counts.

- The adhesive used in perfect binding forms a strong and durable bond.

Cons:

- Cost-effective for longer print runs but may be more expensive for short print runs compared to saddle stitching or spiral binding.

- Not suitable for very thin publications, as the adhesive needs sufficient surface area for a secure bond.

- Perfect-bound books may not lay completely flat when opened.

- Involves drying time for the adhesive, which can extend production time.

Binding Machine Required: Perfect Binders

Case binding/Hard Cover Binding

Case binding, also known as hardcover binding, is a bookbinding method used to create books with rigid and durable covers, typically made of thick cardboard or binder board. This method results in a book with a sturdy, protective cover that encases the pages, offering enhanced durability and a professional appearance.

Pros:

- Highly durable and can withstand extended use and handling.

- Provide a professional and polished appearance, often making them preferred for novels, textbooks, and premium publications.

- The rigid cover provides excellent protection to the pages, preventing damage from bending, tearing, or other physical stress.

- Often associated with higher value and prestige, making them a preferred choice for special editions or collector’s items.

Cons:

- Generally more expensive than softcover or other binding methods, due to the materials and labour involved in the process.

- The binding process can be time-consuming, involving multiple steps such as sewing, drying, and casing-in.

- Do not lay flat when opened, which can be less convenient for reading and taking notes, especially near the spine.

- Not ideal for short runs.

- Bulkier and heavier than softcover alternatives.

By understanding the advantages and applications of these common binding methods, you can make informed decisions when it comes to presenting your documents in a professional and functional manner. Whether you’re a student, a business professional, a designer, or a publisher, the right binding method can enhance the impact of your materials and ensure they stand the test of time.

If you’re a business owner in the office, binding, printing or publishing industry, and you’re seeking the best binding machines to enhance your operations, look no further. Our selection of high-quality binding machines is designed to meet your specific needs. Whether you require the durability of case binding, the versatility of perfect binding, or the cost-effective benefits of saddle stitching, we have the right binding solution for you. Contact us today to explore our range of binding machines and take your business to the next level.