How Does Offset Lithographic Printing Press Process Work?

The offset lithographic printing press process is a cornerstone of the modern press industry, revolutionizing how materials are reproduced and distributed. This intricate and precise method is renowned for its ability to produce high-quality, large-scale prints efficiently and cost-effectively. By delving into the inner workings of the offset lithographic process, we can gain a deeper appreciation for the technology that has played a pivotal role in shaping the world of print, from newspapers and magazines to marketing materials and packaging.

The offset lithographic printing press is one of the many types of printing process that holds relevance across a wide spectrum of industries, including publishing, advertising, packaging, and commercial printing. It applies to businesses and individuals seeking high-quality, large-scale printing solutions for various materials, from magazines and brochures to posters and labels.

In this article, we’ll explore the step-by-step journey of how offset lithographic printing press works, unravelling the complexities behind its remarkable efficiency and impressive results.

What is Offset Lithographic Printing Press?

Offset lithographic printing press, often referred to as offset press, is a widely used commercial printing press technique known for its high-quality results and versatility. It involves transferring ink from a plate to a rubber blanket and then onto the substrate. This indirect press method is based on the principle that water and oil don’t mix, utilizing the repulsion between water and ink to create sharp, detailed images and text on a variety of materials. The offset lithographic printing press is commonly used for producing newspapers, magazines, books, catalogues, brochures, posters, and various packaging materials. It offers consistent, cost-effective, and efficient results, making it a preferred choice for high-volume printing projects.

Understanding how the offset lithographic press process works is essential because it provides insight into a widely utilized printing press technique that forms the basis of various materials we encounter daily, such as newspapers, magazines, and books. This understanding empowers individuals in the design, printing, and publishing industries to create high-quality and visually appealing printed products. Moreover, it enables informed decision-making when choosing printing methods, ensuring that projects align with the capabilities and requirements of offset lithography.

How Does Offset Lithographic Press Process Work?

The offset lithographic press process is a sophisticated and widely used technique that involves several intricate steps to produce high-quality printed materials. To understand this process better, let’s delve into its key stages:

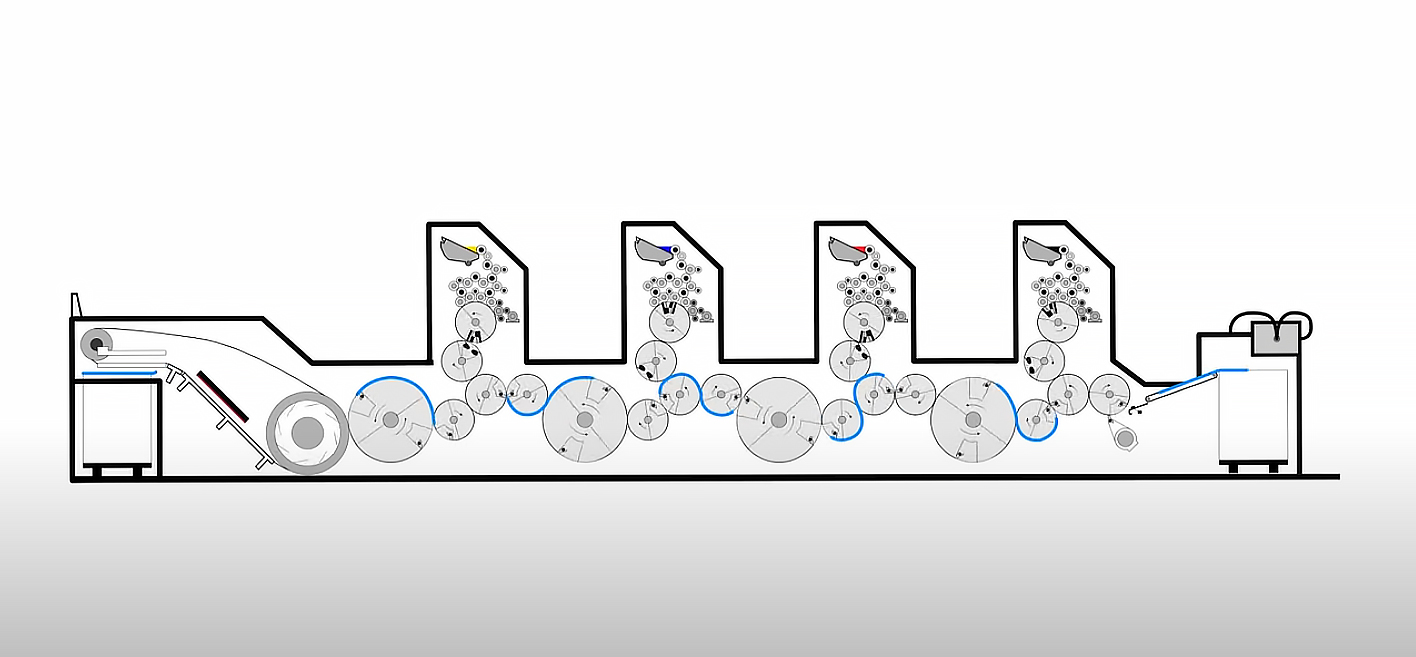

- The image and text design are intricately etched using a laser onto several aluminum sheets referred to as the Press Plate. Each press unit employs one press plate, securely attached to a cylinder.

- Each press unit focus on one colour. Colour printing usually uses ink of four colours – Cyan, Magenta, Yellow and Black, also known as CMYK colour model.

- The stack of paper is elevated into position, and a sheet-separation unit employs jets of air or a vacuum to individuate the paper, ensuring only a single sheet is fed through the press at a given instance.

- As the Press Plate rotates, its first point of contact is the Dampening Unit. This has a mixture of water and other chemicals and dampens the non-image area of the Press Plate.

- Inking the Plate: The ink is applied to the press plate’s image area. This happens by having the Press Plate pass the Inking Unit, starting from the Ink Fountain the ink will pass through multiple rollers called a Roller Train, which then sticks to the image area of the Press Plate.

- Transfer to Blanket Cylinder: Then the press plate passed to the Blanket Cylinder, which then squeezes the water. The rubber blanket cylinder transfers the ink from the plate onto itself.

- Transfer to Impression Cylinder: It then transfers the image to the final cylinder called the Impression Cylinder.

- Transfer to Paper: The next step involves transferring the ink from the rubber blanket cylinder to the paper. The paper passes between the blanket cylinder and the impression cylinder, where pressure ensures precise ink transfer.

- Once the image has been printed, the paper then pas through the Transfer Drums. Each cylinder has grippers that help pick up the paper from the previous cylinder and transfer it to the next printing press unit for the next colour to be printed.

- Drying and Finishing: After the ink is transferred to the paper from every unit, it goes through a drying process to set the image. This step is essential to prevent smudging and ensure the print’s durability. The drying process involves drying the paper with hot and cool air.

Understanding the offset lithographic press process helps professionals in various industries, from graphic design to publishing, make informed decisions about their printing projects. It can also help pinpoint any quick maintenance and troubleshooting checks needed for any press issues encountered during the entire process. It showcases the complexity and precision involved in producing high-quality press materials efficiently and at scale.

If you’re looking to establish or enhance your offset lithographic press setup, PRINTFINISH can help you every step of the way. Our team of experts is well-versed in the intricacies of the offset lithographic printing press process, and we understand the unique requirements of your business. Whether you’re just starting out or seeking to expand your capabilities, our tailored solutions and guidance will ensure that your offset lithographic press venture flourishes. Contact us today to explore how we can help you achieve success in the world of printing press.