How Lamination Protects and Enhances Printed Materials

In the world of printed materials, durability and visual appeal are essential for maintaining a professional image and ensuring the longevity of the product. Whether it’s a business card, a menu, a poster, or a brochure, these materials are often subjected to frequent handling and environmental exposure. Lamination is a powerful finishing process that addresses these challenges, offering both protection and enhancement to printed items. By applying a thin layer of plastic film to the surface of a print, lamination serves dual purposes: safeguarding the material and elevating its aesthetic qualities. This article explores how lamination protects and enhances printed materials, making it an indispensable step in the print finishing process.

What is Lamination?

Lamination is the process of applying a thin plastic film to the surface of printed materials to enhance both their durability and visual appeal. This protective layer safeguards the material against damage from moisture, dirt, and frequent handling, while also preventing issues like fading, tearing, and smudging. Available in various finishes such as gloss, matte, and soft-touch, lamination not only adds a unique aesthetic but also improves the tactile experience. Beyond protection, lamination elevates the functionality and professional appearance of printed items, ensuring they remain long-lasting and visually striking.

Extending the Life of Printed Materials

One of the primary reasons to laminate printed materials is to protect them from damage caused by everyday use and environmental factors. Printed products are vulnerable to tearing, smudging, and discoloration, especially when handled frequently or exposed to elements such as moisture, dirt, or sunlight. Lamination creates a barrier that shields the material, ensuring its integrity over time.

- Moisture Resistance: Lamination makes printed items waterproof, an essential feature for materials used in environments where exposure to liquids is likely, such as restaurant menus, beverage coasters, or outdoor posters. Without lamination, even a minor spill could ruin the material, rendering it unusable.

- Tear and Wear Resistance: Printed materials, particularly those made from standard paper or card stock, are prone to tearing and creasing. Lamination adds a layer of strength, making the material more robust and less likely to succumb to wear and tear. This is particularly useful for items like educational flashcards, business cards, or presentation folders, which are often handled repeatedly.

- UV Protection: Exposure to sunlight can cause printed materials to fade over time, diminishing their quality and impact. Lamination with UV-resistant film helps to mitigate this issue by protecting the ink and paper from harmful ultraviolet rays, ensuring that colours remain vibrant and legible.

- Stain and Smudge Prevention: Printed surfaces are vulnerable to stains from fingerprints, oils, or accidental marks. Lamination creates a smooth, wipeable surface that resists these stains, keeping the material clean and professional-looking.

By addressing these vulnerabilities, lamination significantly extends the lifespan of printed materials, making it a cost-effective solution for businesses and organizations that require durable products.

Improving Visual and Tactile Appeal

While lamination offers unparalleled protection, it also enhances the aesthetic and tactile qualities of printed materials, elevating their overall presentation. The right lamination finish can transform a simple print into a high-quality product that stands out.

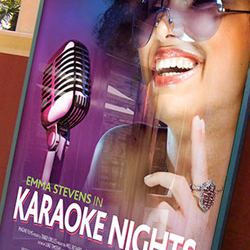

- Glossy Finish: Gloss lamination gives materials a shiny, reflective surface that enhances colours and sharpens images. This finish is ideal for marketing materials such as posters, flyers, and product packaging, where bold visuals are essential to capture attention. The glossy effect makes images appear more vibrant and text more defined, creating a visually striking result.

- Matte Finish: For a more understated and elegant look, matte lamination provides a soft, non-reflective surface. It reduces glare and adds a sophisticated touch, making it an excellent choice for materials like corporate brochures, menus, and luxury invitations. Additionally, matte lamination resists fingerprints and smudges, ensuring a clean appearance even after frequent handling.

- Soft-Touch Finish: Soft-touch lamination creates a velvety texture that enhances the tactile experience of the printed material. This luxurious finish is commonly used for premium products such as high-end business cards, presentation folders, and packaging for luxury goods. The unique feel of soft-touch lamination leaves a lasting impression on recipients, making it a valuable tool for branding and marketing.

- Stiffness and Structure: Beyond aesthetics, lamination adds stiffness to printed pieces, giving them a more substantial feel. This added rigidity not only makes the material more durable but also conveys a sense of quality and professionalism.

- Writable Surface: Laminated surfaces can often be written on with dry-erase markers, adding functionality to items such as training materials, calendars, or reusable charts.

Applications of Lamination

Lamination is a versatile finishing technique that can be applied to a wide range of printed materials. Some of its most common applications include:

- Marketing Materials: Flyers, posters, and brochures that require vibrant colours and durability.

- Business Essentials: Business cards, certificates, and presentation folders that benefit from a polished and professional look.

- Educational Tools: Flashcards, maps, and instruction manuals that need to withstand frequent handling.

- Hospitality Items: Menus and signage for restaurants and hotels, where exposure to liquids and frequent use are common.

- Outdoor Prints: Banners and posters are designed for outdoor use, where protection against weather elements is critical.

Reducing the Need for Reprints

Although lamination adds to the upfront cost of producing printed materials, it is a cost-effective investment in the long run. By preventing damage and maintaining the material’s quality, lamination reduces the frequency of reprints. This is especially beneficial for businesses that rely on durable materials, such as retail stores with signage or restaurants with menus that are used daily.

Moreover, laminated materials project a professional image that reflects positively on a brand. High-quality, well-maintained printed materials can leave a lasting impression on customers, partners, and stakeholders, helping businesses stand out in a competitive market.

Lamination plays a vital role in protecting and enhancing printed materials, ensuring they remain functional, visually appealing, and durable over time. By shielding materials from damage and improving their aesthetics, lamination extends the life and effectiveness of print products, making it an essential step in the finishing process. Whether for marketing materials, business essentials, or educational tools, lamination offers unmatched value, helping businesses and organizations create impactful, professional, and long-lasting printed materials.

If you’re a business owner in the office, binding, printing or publishing industry, and you’re seeking the best print-finishing machine to enhance your operations, look no further. Our selection of high-quality equipment is designed to meet your specific needs. Whether you require the durability of binding, the versatility of cutters, or the cost-effective benefits of large-format printers, we have the right binding solution for you. Contact us today to explore our range of binding machines and take your business to the next level.