How Using Vinyl Cutter Equipment Helps in Window Tinting and Paint Protection Business

Window tinting and paint protection film for cars rapidly emerge as a lucrative and in-demand business opportunity. As more individuals and businesses recognize the benefits of window tinting and paint protection films, there is a growing need for skilled professionals who can provide these services. Window tinting offers numerous advantages, including enhanced privacy, UV protection, and improved energy efficiency. Similarly, paint protection films shield vehicles’ exterior surfaces from scratches, rock chips, and other damages, preserving the car’s aesthetic appeal and resale value. With the increasing popularity of these services, entrepreneurs entering the window tinting and paint protection film industry can tap into a thriving market and capitalize on the growing demand for these valuable solutions.

Technological advancements have revolutionized various vinyl cutting equipment, especially the window tinting and paint protection film industry, enhancing efficiency, precision, and overall customer satisfaction. Cutting-edge vinyl cutting equipment now allows businesses to provide high-quality window films and paint protection films, providing a unique and personalized experience for customers. These advancements enable precise fitting and installation, minimizing errors and improving the overall quality of the end result. With innovative vinyl-cutting technologies, businesses in the window tinting and paint protection film industry can offer enhanced products, superior protection, and unparalleled craftsmanship, setting themselves apart in a competitive market.

What’s Involved in Window Tinting and Paint Protection Film Business

The realm of window tinting and paint protection film business is a dynamic and rapidly evolving landscape, encompassing a range of cutting-edge techniques and innovative solutions. This section of the article delves into the intricate details of this industry, unravelling the essential elements that make up the window tinting and paint protection film business. From the art of precise application to the science of safeguarding vehicle surfaces, let’s explore the comprehensive landscape of what’s involved in this thriving sector.

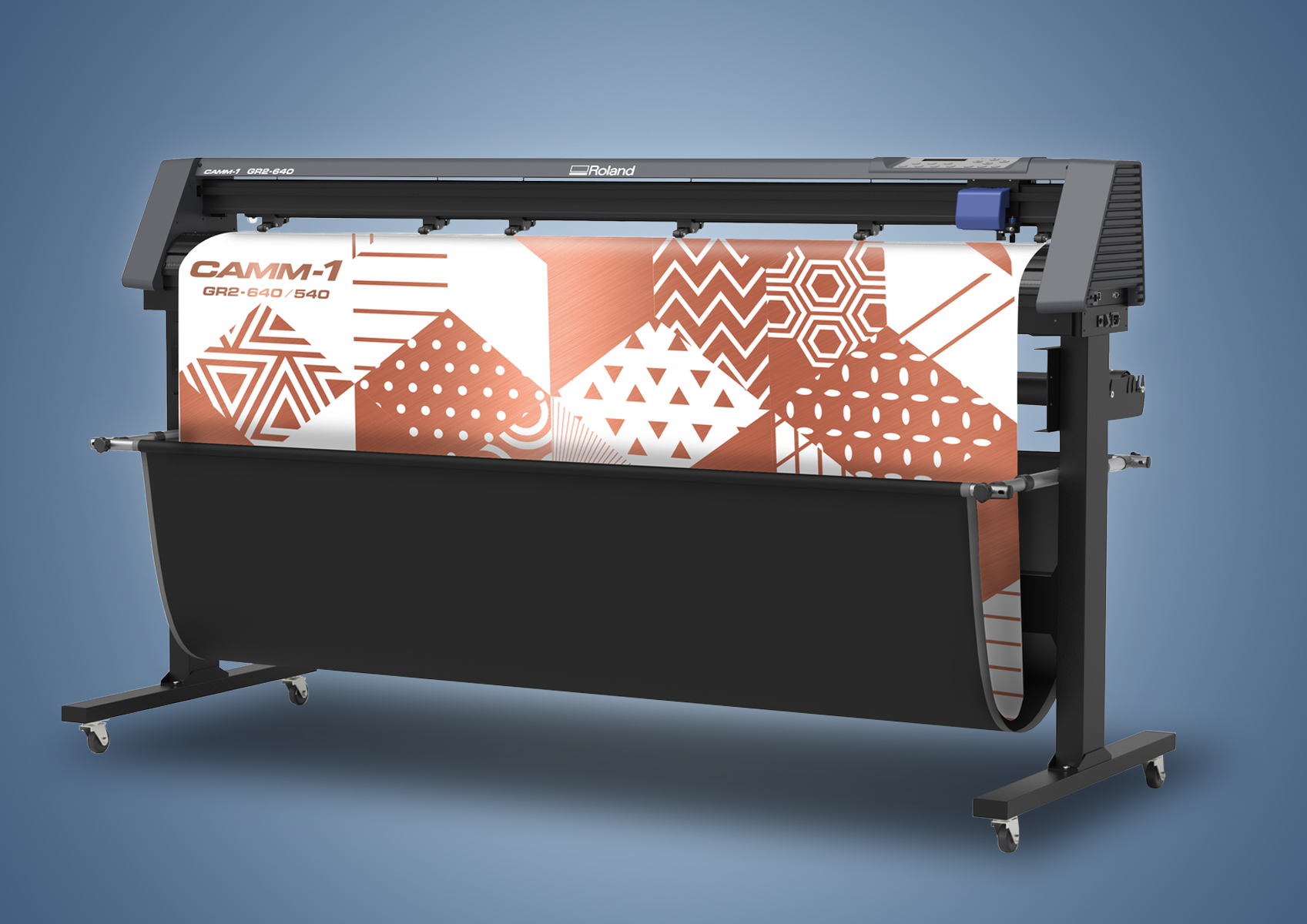

- Cutting Equipment – A cutting-edge cutter with a substantial width, typically ranging from 54″ to 64″. A good example is from Roland digital printing solutions, the Roland CAMM1 GR2 series (more of this in the next paragraph).

- A subscription to a template provider – A company that creates the various tint and PPF patterns that are specific to the cars being sold and available in your market. A subscription ensures that you receive the most accurate up-to-date templates for the latest model of vehicles.

- Quality Tint Film – this ensures optimal privacy and UV protection for vehicles There are many different types of tint films that car owners can choose from, ranging from Dyed Window Tint, Metalized Window Tint, Carbon Tint Film, Crystalline Window Tint and Ceramic Window Tint to name a few. Note: ceramic infused film is considered the best type of tint you can get, as it’s developed using small ceramic-based particles that are highly non-conductive.

- Paint Protection Film (PPF) – A clear protective layer applied to vehicle exteriors to shield them from scratches, rock chips, and other potential damages while maintaining the original appearance. This is typically applied to high-impact areas like hood, fenders and bumpers, though it can also be applied to other areas as well.

It can also be ceramic coated manually to protect the car body even more. need to do some research on PPF and ceramic coating. - Ceramic Coating – a liquid polymer applied to the exterior surfaces of a vehicle to provide an additional layer of protection and shine. It forms a protective barrier that enhances the car’s resistance to UV rays, chemicals, and contaminants, while also offering hydrophobic properties for easier cleaning and maintenance. Ceramic coatings have a higher initial cost though won’t require frequent maintenance, unlike PPF which requires regular attention.

Best Vinyl Cutting Equipment for Window Tinting/Paint Protection Film Business

Finding the right cutter is crucial for your business in achieving exceptional results. With a wide range of options available, it is important to have a guide in selecting the ideal cutter for window tinting that meets your specific needs, ensuring outstanding cut quality, efficiency, and reliability.

After more than three decades, Roland DG still leads the industry when it comes to vinyl contour-cutting technology. With its precision cutting and advanced capabilities, Whether you’re looking for large format vinyl cutter machines or desktop vinyl plotters, Roland DG technology offers the best equipment for the window tinting business.

The Roland CAMM-1 GR2 Series stands as one of the best vinyl cutters for window tinting and paint protection businesses, delivering exceptional performance and versatility. CAMM-1 GR2 vinyl cutter allows businesses to achieve outstanding results with efficiency and remarkable precision. Its user-friendly interface and reliable operation make it an invaluable asset for businesses looking to excel in the window tinting and paint protection industry.

Benefits of Incorporating Vinyl Cutting Equipment in Window Tinting Business

Incorporating vinyl-cutting equipment into a window tinting business offers a plethora of advantages. Here are some of the key benefits:

- Precision and Accuracy: Enables precise and accurate cutting of window tint films, ensuring clean edges. This level of precision enhances the overall quality and appearance of the finished product, meeting customer satisfaction.

- Efficiency and Time Savings: With vinyl cutting technology, window tinting professionals can significantly reduce the time required for cutting tints. The automated cutting process streamlines workflows, allowing for faster turnaround times and increased productivity.

- Customization: You can cut anything from a standard template in one colour of window film to custom lettering and logos in single or multiple colours. This capability opens the door to creative possibilities, enabling businesses to offer unique and personalized solutions to their customers.

- Consistency: Vinyl cutters ensure consistent and uniform cuts across multiple pieces, eliminating variations that can occur with manual cutting methods. This consistency contributes to a professional and polished end result.

- Waste Reduction: Vinyl-cutting technology optimizes material usage by minimizing waste. Precise cutting minimizes the need for excess film, leading to cost savings and a more eco-friendly approach.

- Enhanced Professionalism: The use of vinyl cutting equipment adds a professional touch to the window tinting process. Clean and accurately cut window tint films is miles better than a crooked cut.

Incorporating vinyl-cutting equipment into a window tinting business not only enhances the quality and efficiency of the services provided but also opens up new avenues for creativity and customer satisfaction.

BONUS TIPS: Other Value-Added Services That Can Help Window Tinting Business

Aside from having a paint protection film service, here are some other value-added services for your window tinting business:

- Automotive Restyling – encompasses a wide range of vehicle updates, including window tint, paint colour change wrap, upgraded accessories, clear bras, car audio and video systems, paint protection film, etc. In recent years, more and more vehicle owners are choosing to keep their cars, SUV’s and trucks rather than trading them in. So why not invest in some services that could help extend a car’s life?

- Offering Vehicle Decal Creation – Similar to the evolution of vinyl cutting technology, the progress in printing technology has led to significant enhancements that span across various applications, including vehicle decals. Everything from a pink tank to a series-winning NASCAR race car has been wrapped with a Roland DG printer like Roland DG TrueVIS VG3 Series.

The window tinting and paint protection industry is experiencing a wave of emerging trends and future possibilities. Advancements in nanotechnology and materials science are paving the way for more advanced coating solutions. These innovations include self-healing coatings and improved scratch resistance, which can enhance the longevity and durability of paint protection films. By leveraging advanced cutting techniques through advanced cutting equipment, businesses can offer high-quality and resilient paint protection films to their customers.

Are you considering investing in a cutting machine for your window tinting business? Look no further! Our team of experts is here to guide you through the process and provide valuable insights to help you make an informed decision. With years of experience in the industry, we understand the specific requirements and challenges of window tinting businesses. Whether you need advice on the best cutter model or workflow optimization, our experts are ready to assist you. Don’t miss out on the opportunity to enhance your business with the right cutting machine. Contact us today for a personalized consultation and take your window tinting business to new heights.