10 Tips to Remember When Buying a Wire Binding Machine

Choosing the right wire-binding machine is critical for businesses and individuals looking to produce professional and durable documents. Here, we’ll explore the essential tips to consider when purchasing a wire binding machine, ensuring you make an informed choice that meets your needs. Whether in an office, educational institution, print shop, or any industry requiring frequent document binding, understanding the key features, capabilities, and maintenance requirements of wire binding machines is crucial. We will cover aspects such as machine capacity, ease of use, durability, and cost, helping you select the best equipment for your binding tasks.

First, What is a Wire Binding?

Wire binding is a popular document binding method that involves using a metal wire or wire-o spine to bind the pages of a document together securely. This technique involves punching evenly spaced holes along the edge of the pages and then threading a metal wire through these holes. The wire is then clamped shut, holding the pages firmly in place. Wire binding is known for its durability and professional appearance, making it a preferred choice for presentations, reports, manuals, and other high-quality documents. It allows documents to lay flat when opened and accommodate many page counts.

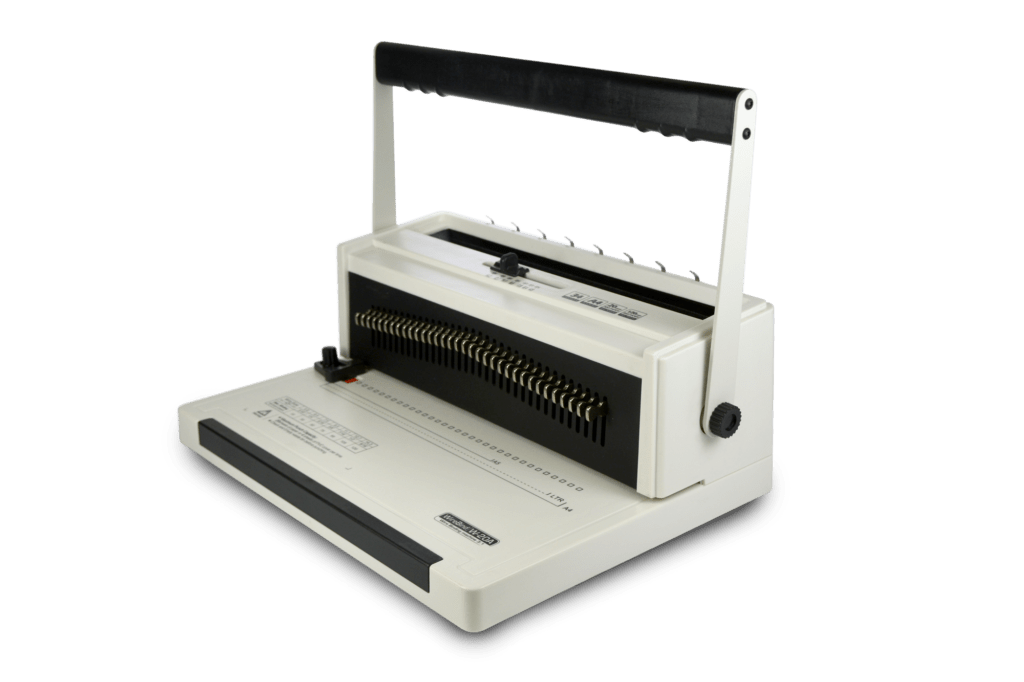

What is a Wire Binding Machine Then?

A wire binding machine is a specialized device that binds documents using metal wires or wire-o spines. This machine punches evenly spaced holes along the edge of the document and then threads a wire spine through these holes to securely hold the pages together. Wire binding machines come in various sizes and capacities, catering to different binding needs from small office tasks to large-scale commercial printing. They are widely used in offices, educational institutions, and print shops for creating professional-looking reports, manuals, presentations, and other types of bound documents.

10 Tips to Remember Before Buying a Wire Binding Machine

Before purchasing a wire binding machine, consider the following tips to ensure you select the right model for your needs:

- Binding Capacity: Determine the maximum number of pages you need to bind regularly and choose a machine that can handle that capacity.

- Document Size: Ensure the machine can accommodate the sizes of documents you frequently bind, such as standard letter size, legal size, or larger formats.

- Punching Capacity: Check how many sheets of paper the machine can punch at once to match your workload and efficiency needs.

- Ease of Use: Use user-friendly features such as easy alignment guides, adjustable settings, and clear instructions to simplify the binding process.

- Durability: Consider the build quality and materials of the machine to ensure it can withstand frequent use and provide long-term reliability.

- Adjustability: Choose a machine with adjustable settings for hole spacing and margin depth to accommodate different binding projects.

- Additional Features: Consider machines with added features such as electric punching, interchangeable dies, or built-in wire closers to enhance functionality and efficiency.

- Budget: Set a budget and compare machines within your price range, balancing cost with the features and capabilities you need.

- Brand and Reviews: Research reputable brands and read customer reviews to gauge the reliability and performance of the machine you are considering.

- Support and Warranty: Check the availability of customer support, warranty, and maintenance services to ensure you have assistance if issues arise.

By keeping these tips in mind, you can make an informed decision and choose a wire binding machine that meets your specific requirements and provides reliable performance.

Why Wire Binding (and Other Binding Methods) is Important

Wire binding, along with other binding methods, plays a crucial role in various sectors by enhancing the functionality and presentation of documents. Here’s why binding is important:

Professional Appearance:

- Wire Binding: Provides a sleek, professional look, making it ideal for reports, presentations, and proposals.

- Other Methods: Methods like perfect binding and hardcover binding also offer a polished appearance, suitable for high-end publications like books and annual reports.

Durability:

- Wire Binding: Ensures that documents remain intact over time, even with frequent handling.

- Other Methods: Spiral binding and case binding provide similar durability, protecting the integrity of documents through heavy use.

Ease of Use:

- Wire Binding: Allows documents to lay flat when opened, improving readability and usability.

- Other Methods: Saddle stitching offers easy page flipping, while perfect binding provides a smooth spine for easy stacking and shelving.

Customization:

- Wire Binding: Accommodates various document sizes and thicknesses, offering flexibility for different projects.

- Other Methods: Comb binding and spiral binding also allow for customization in terms of page count and document size.

Organization:

- Wire Binding: Keeps pages securely fastened and in order, preventing loss and disorganization.

- Other Methods: Binding methods like saddle stitching and comb binding similarly ensure that all pages stay together, improving document management.

Enhanced Presentation:

- Wire Binding: Adds a professional touch that can impress clients, stakeholders, and readers.

- Other Methods: Each binding method can enhance the presentation in different ways, such as the classic look of hardcover binding or the clean finish of perfect binding.

Cost-Effectiveness:

- Wire Binding: Offers a balance between affordability and quality, suitable for various budgets.

- Other Methods: Saddle stitching is particularly cost-effective for smaller documents, while comb and spiral binding are economical options for larger quantities.

Environmental Considerations:

- Wire Binding: Metal wires can be recycled, contributing to sustainability efforts.

- Other Methods: Some binding methods use recyclable materials, supporting eco-friendly practices.

In summary, binding methods, including wire binding, are essential for creating durable, organized, and professional-looking documents. They are widely used across different industries such as education, corporate, publishing, and printing, helping to enhance the presentation and usability of various printed materials.

Best Wire Binding Machine in 2024

Here are some of the best wire-binding machines:

- WireBind W20A Wire Binding Machine

- Supu CW430E Electric Wire-o Punching Machine with Manual Closer

- WireMac-E31 Akiles Electric Punch Manual Wire

- Akiles WBM532 Modular Wire Binding Machine

- Akiles FlexiCloser 2 Wire Binding Machine

Selecting the right wire binding machine requires careful consideration of various factors such as binding capacity, document size, ease of use, durability, and budget. By understanding your specific needs and evaluating machines based on these criteria, you can make an informed decision that enhances your document production process. Remember to research reputable brands, read customer reviews, and consider the availability of support and warranty services to ensure a smooth and satisfying purchase experience. Investing in a high-quality wire binding machine will not only improve the appearance and durability of your documents but also increase efficiency and productivity in your binding tasks.

If you’re a business owner in the office, binding, printing or publishing industry, and you’re seeking the best wire binding machines to enhance your operations, look no further. Our selection of high-quality binding machines is designed to meet your specific needs. Whether you require the durability of case binding, the versatility of perfect binding, or the cost-effective benefits of saddle stitching, we have the right binding solution for you. Contact us today to explore our range of binding machines and take your business to the next level.