7 Maintenance Tips for Your Wire Binding Machine

Ensuring the proper maintenance of equipment is essential for efficiency and longevity. In this article, we’ll delve into the importance of proper maintenance for wire-binding machines and why it’s crucial for businesses, offices, print shops, and other sectors where document binding is a routine task. Whether you’re a small business owner, a printing professional, or an office administrator, understanding how to maintain your wire binding machine can help you maximize its performance, minimize downtime, and prolong its lifespan. We’ll cover essential maintenance tasks, troubleshooting tips, and best practices to keep your wire binding machine running smoothly and producing high-quality bound documents consistently. By investing time and effort into proper maintenance, you can ensure that your wire binding machine remains a reliable tool in your document management arsenal.

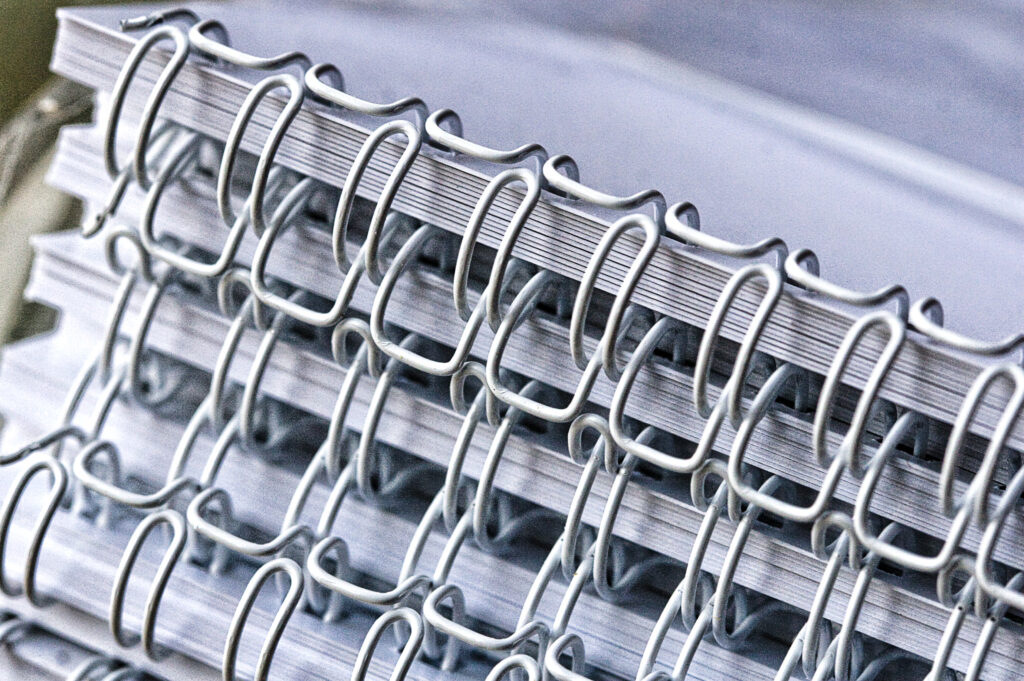

What is a Wire Binding?

First, let us understand what the wire binding method is. The wire binding method is a document binding technique that involves using a metal wire or coil to securely bind the pages of a document together. This method typically utilizes a specialized wire binding machine to punch evenly spaced holes along the edge of the document and then thread the wire through these holes. Once the wire is threaded through, it is closed using a wire closer to securely hold the pages in place. Wire binding provides a durable and professional-looking finish, allowing documents to lay flat when opened for easy reading and referencing. It is commonly used for reports, presentations, manuals, calendars, and other types of documents across various industries.

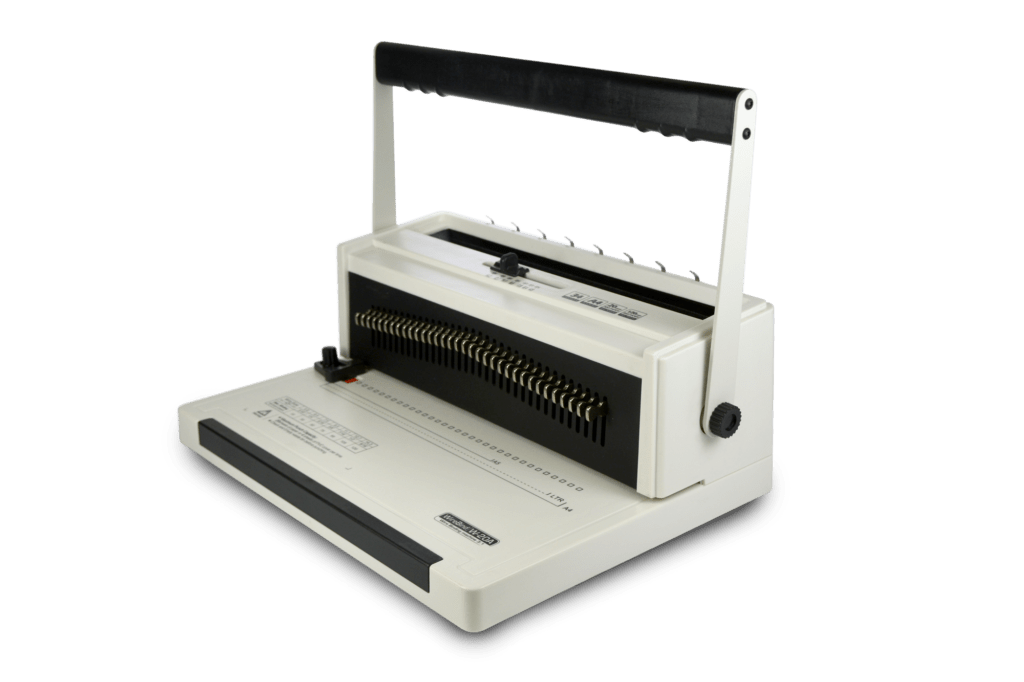

Also, a wire binding machine is a specialized piece of equipment used for binding documents using wire binding coils. Also known as wire binders or wire closers, these machines are commonly used in offices, print shops, copy centers, and other businesses where document binding is a regular task. Wire binding machines come in various sizes and capacities, ranging from small desktop models suitable for occasional use to larger industrial-grade machines capable of high-volume production.

The primary function of a wire binding machine is to punch evenly spaced holes along the edge of the document and then thread a wire binding coil through these holes to securely bind the pages together. These machines typically feature adjustable settings to accommodate different paper sizes, hole patterns, and wire sizes. Some advanced models may also include additional features such as built-in wire closers, electric punching capabilities, and foot pedals for hands-free operation.

Wire binding machines are versatile tools that offer several advantages, including durability, professional appearance, and the ability to lay flat when opened. They are commonly used for binding reports, presentations, manuals, calendars, and other documents where a sleek and professional finish is desired. Proper maintenance of a wire binding machine is essential to ensure optimal performance, longevity, and the production of high-quality bound documents consistently.

Why is Maintenance Important?

Maintenance of binding machines is crucial for optimal performance, longevity, and consistent quality of bound documents. Regular upkeep helps prevent malfunctions, extends equipment lifespan, and reduces downtime. It also ensures safety, saves costs on repairs, and may be necessary for compliance with regulations. Proper maintenance minimizes the risk of accidents, enhances productivity, and preserves the professional appearance of documents.

7 Things to Remember When Doing Maintenance on Your Wire Binding Machine

When maintaining your wire binding machine, keep the following in mind:

- Regular Cleaning: Remove debris and residue to prevent jams and ensure smooth operation.

- Lubrication: Apply lubricant to moving parts according to manufacturer recommendations to prevent wear and tear.

- Inspection: Regularly inspect the machine for damaged or worn parts, and replace them as needed to avoid breakdowns.

- Calibration: Ensure that the machine is properly calibrated to punch holes and close wires accurately.

- Proper Use: Follow the manufacturer’s instructions for operation and avoid overloading the machine to prevent damage.

- Safety Precautions: Always turn off the machine before performing maintenance tasks and use appropriate safety gear.

- Professional Servicing: Consider periodic servicing by a qualified technician to maintain optimal performance.

By adhering to these maintenance tips, you can prolong the lifespan of your wire binding machine and ensure consistent, high-quality results.

Advantages of Having a Well-Maintained Wire Binding Machine

Maintaining a wire binding machine is crucial for ensuring its optimal performance and longevity. Here are the advantages of having a well-maintained wire binding machine:

- Optimal Performance: Smooth operation and reliable binding, minimizing downtime.

- Longevity: Extends machine lifespan, reducing the need for costly repairs or replacements.

- Consistent Quality: Produces high-quality bound documents consistently, enhancing professionalism.

- Safety: Reduces the risk of accidents or injuries to users, ensuring a safe working environment.

- Cost Savings: Saves money on repairs and replacements, maximizing return on investment.

- Compliance: Helps meet safety regulations and industry standards, avoiding penalties.

- Productivity: Enhances workflow efficiency, increasing productivity and overall output.

You further check our most frequently asked questions about wire binding.

Best Wire Binding Machines in 2024

Here are some of the best wire-binding machines:

- WireBind W20A Wire Binding Machine

- Supu CW430E Electric Wire-o Punching Machine with Manual Closer

- WireMac-E31 Akiles Electric Punch Manual Wire

- Akiles WBM532 Modular Wire Binding Machine

- Akiles FlexiCloser 2 Wire Binding Machine

In conclusion, proper maintenance of a wire binding machine is essential for ensuring its optimal performance and longevity. By adhering to the maintenance tips outlined in this article, users can minimize downtime, reduce the risk of malfunctions, and prolong the lifespan of their equipment. Regular cleaning, lubrication, inspection, and calibration are key practices that can help keep wire binding machines in top working condition. Additionally, prioritizing safety, investing in professional servicing when needed, and following manufacturer recommendations for use are essential aspects of effective maintenance. By incorporating these maintenance tips into their routine, users can maximize the efficiency, reliability, and lifespan of their wire-binding machines, ultimately contributing to a more productive and successful document-binding process.

If you’re a business owner in need of the best binding machines to enhance your document organization and presentation, look no further. Our comprehensive range of high-quality binding equipment is designed to meet your specific needs, whether you run an office, a binding business, or a printing venture. Streamline your operations, impress clients, and leave a lasting impression with our top-notch binding solutions. Contact us today to explore the perfect binding machine that aligns with your requirements, and take the first step toward optimizing your document management and presentation capabilities.