Print Finishing 101: What is Lamination

In the printing world, creating visually appealing and long-lasting materials goes beyond high-quality design and vibrant ink. A key part of achieving that premium finish lies in the post-print stage, specifically in the finishing processes. Among these, lamination stands out as one of the most widely used and effective methods for enhancing both the look and durability of printed items. From business cards and book covers to menus and product packaging, lamination is crucial in protecting print from everyday wear and giving it a professional edge. This article explores lamination as a print finishing process—what it is, how it works, its benefits, and its broad applications.

What Is Lamination?

Lamination is the process of applying a thin layer of plastic film over printed materials to protect and enhance their surface. The film acts as a barrier that shields the ink and paper from moisture, dirt, grease, fingerprints, and physical wear such as scratches or tears. It also adds a smooth, often glossy or matte finish that enhances colour depth and overall presentation.

Lamination is available in several finishes:

- Gloss: Offers a shiny, reflective look that makes colours appear more vibrant.

- Matte: Provides a soft, non-reflective finish that reduces glare and gives a modern, elegant appearance.

- Soft-touch: Delivers a velvety texture that adds a tactile, luxurious feel to the printed material.

The choice of laminate depends on both aesthetic preference and functional need, making it a versatile option for a wide variety of print projects.

How Lamination Works

The lamination process typically involves heat or pressure (or both) to bond the plastic film to the printed surface. There are two main types:

- Thermal Lamination: The most common method, where the plastic film is coated with heat-activated adhesive. As the film passes through heated rollers, it melts slightly and adheres firmly to the paper.

- Pressure-Sensitive (Cold) Lamination: This method uses films with adhesive that bonds to the paper without heat, often used for heat-sensitive materials or quick-turnaround projects.

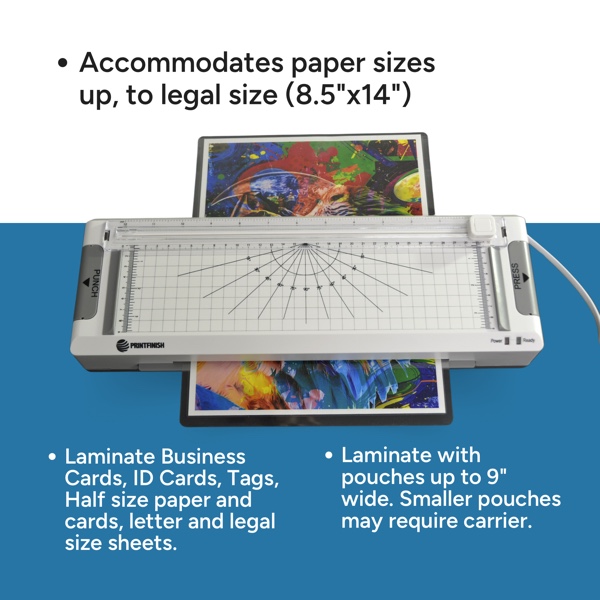

The laminating film comes in different thicknesses, usually measured in microns or mils. Thicker films provide greater protection and rigidity, while thinner films are more flexible and cost-effective. These films are applied using a laminator, a machine that uses precise heat and pressure to ensure an even, bubble-free finish across the material.

Benefits of Lamination

Lamination offers a range of practical and aesthetic advantages that make it a popular choice for enhancing printed materials. Below are some of the key benefits:

1. Durability and Protection

The primary purpose of lamination is to protect printed materials from physical and environmental damage. Laminated items resist tearing, creasing, and smudging and are less susceptible to water or chemical spills. This makes lamination ideal for materials that are frequently handled, displayed outdoors, or exposed to challenging environments, such as restaurant menus, ID cards, instruction manuals, and product labels.

2. Improved Appearance

Lamination enhances visual appeal by intensifying colours, adding contrast, and giving the material a sleek finish. Glossy lamination brings out the vibrancy of colours and images, while matte finishes offer a subtle, high-end look. Soft-touch lamination, often used for luxury packaging and business cards, gives a unique tactile quality that adds sophistication and memorability.

3. Professionalism and Brand Perception

Professionally laminated materials convey quality and attention to detail. Whether it’s a business presentation folder, a product brochure, or a corporate ID badge, the smooth, protected surface signals that the content is valuable and the brand behind it is professional. For businesses, this small upgrade can help influence customer perceptions and boost brand credibility.

4. Water and Stain Resistance

Laminated materials are easier to clean and maintain. A quick wipe with a damp cloth can remove smudges, fingerprints, or food stains, making lamination ideal for items used in hospitality, retail, and healthcare industries.

5. Longevity and Cost Efficiency

While lamination adds to the initial cost of a print job, it can save money over time by reducing the need for reprints. Laminated materials have a much longer lifespan, maintaining their quality and integrity even after repeated use.

Common Applications of Lamination

Lamination is used across a wide range of industries and for various purposes. Some common applications include:

- Business cards: Adds a premium finish and protects against edge wear.

- Menus: Ensures resistance to spills and daily handling.

- Instructional materials: Protect documents used in schools, workshops, or industrial settings.

- Book covers and catalogues: Extends the life of printed materials with frequent use.

- Posters and signage: Make visuals more durable for indoor and outdoor use.

- Packaging: Provides a professional finish and barrier for product labels and cartons.

- Certificates and IDs: Ensures security and longevity for official documents.

Laminated items can be produced using a wide variety of laminating pouches & rolls, depending on the size, thickness, and type of finish required.

Best Lamintors in 2025

If you’re looking for reliable equipment to support your lamination needs, here are some top options to consider:

- Sysform All-in-One Digital Laminator & Foiler FL-360

- SUPU FM-480 Roll Laminator 19″

- Akiles ProLam Plus 330 13″ Pouch Laminator

- Sigmont 55H/65H Roll Laminator

- Royal Sovereign RSL 2702S

Things to Consider

Although lamination offers many advantages, there are a few considerations to keep in mind:

- Laminated paper is more difficult to recycle due to the plastic film, so it may not be the best option for sustainability-focused projects unless biodegradable laminates are used.

- While relatively affordable, lamination does add to production costs. For large volumes or limited-use items, it may not be necessary.

- Dark, solid colours or metallic inks can sometimes show imperfections more clearly after lamination, so designs should be tested beforehand.

Lamination is a highly effective print finishing process that protects printed materials and elevates their visual and tactile appeal. Whether you need to enhance durability, improve appearance, or create a more professional presentation, lamination offers a practical and versatile solution. With multiple finishes and thicknesses to choose from, it can be tailored to suit a variety of needs, from rugged instruction manuals to high-end product packaging. While it may add to the cost, the added value, longevity, and brand impact often make lamination a worthwhile investment in any quality print project.

If you’re a business owner in the office, binding, printing or publishing industry, and you’re seeking the best print-finishing machine to enhance your operations, look no further. Our selection of high-quality equipment is designed to meet your specific needs. Whether you require the durability of binding, the versatility of cutters, or the cost-effective benefits of large-format printers, we have the right binding solution for you. Contact us today to explore our range of binding machines and take your business to the next level.