Binding 101: What Is A Perfect Binding?

Perfect binding is a sophisticated and widely employed bookbinding technique that adds a touch of professionalism to a diverse range of printed materials. Whether you’re crafting a novel, magazine, or corporate report, perfect binding offers a sleek and seamless finish that captivates both visually and tactually. This method involves securely gluing together the pages of a publication to a flat spine and attaching a cover, resulting in a clean and polished appearance that not only elevates the aesthetics of the printed piece but also ensures durability. Let’s delve into the intricacies of perfect binding, unravelling the artistry behind its creation and its applications in high-quality printed products.

What is a Perfect Binding?

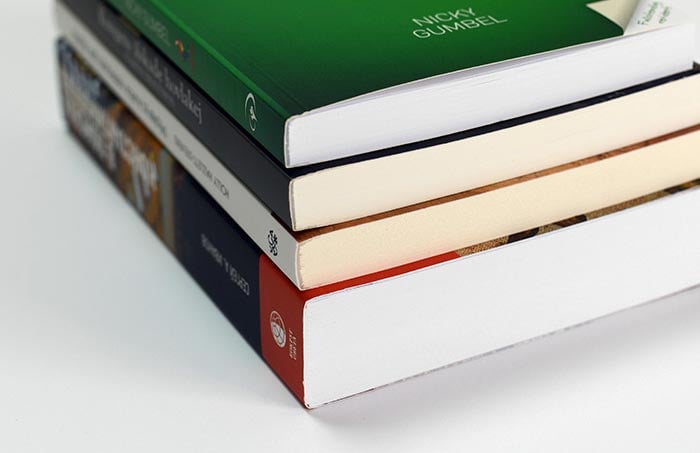

Perfect binding is a sophisticated bookbinding method commonly used for creating paperback books, magazines, catalogues, and other printed materials with a professional finish. In the perfect binding process, individual pages or signatures are stacked together, and a flexible adhesive is applied to the spine edge. The pages are then attached to a cover, creating a square spine. This method results in a sleek and streamlined appearance, making it a popular choice for publications where a polished and refined look is desired.

One distinctive feature of perfect binding is the absence of staples or stitching along the spine, contributing to a clean and uninterrupted surface. This binding technique accommodates larger page counts compared to saddle stitching and is suitable for a variety of project sizes, from thin booklets to thick volumes. Perfect binding not only enhances the visual appeal of printed materials but also provides a durable and professional solution for a range of publishing needs.

Why is Binding Important?

Binding is an important aspect of the printing process that serves both practical and aesthetic purposes. Structurally, it imparts integrity to a collection of pages, ensuring they remain organized and in sequence. This enhances the durability of printed materials, protecting them from wear and tear during handling and transportation. Beyond functionality, binding contributes to the aesthetic appeal of a publication, influencing its perceived quality and professionalism. The choice of binding method also aligns with the intended use of the material, with different methods offering specific advantages, such as the ease of page-turning or the ability to lie flat for note-taking. Ultimately, binding plays a pivotal role in creating visually appealing, well-organized, and durable printed materials that effectively convey information to readers.

How Does Perfect Binding Work?

Best Perfect Binding Machines

Here are some of the best perfect binding machines:

- Boway Perfect Binder BW-JB2

- Boway Perfect Binder BW-920V

- Sysform 50A Professional Perfect Binding Machine

- Sysform 50B Professional Perfect Binding Machine

In conclusion, perfect binding emerges as a versatile and cost-effective method for creating professionally bound paperback books, magazines, and other publications. The process results in a sleek, flat-spined finished product. While perfect binding may not offer the same durability as certain alternatives like sewn or hardcover binding, its widespread use stems from its ability to provide a clean, organized, and visually appealing presentation at an accessible cost. Whether bringing novels to life or compiling informative catalogues, perfect binding stands as a practical and efficient choice in the world of bookbinding, combining functionality with a polished aesthetic.

Are you a business owner seeking to elevate the presentation of your publications, from catalogues to manuals and beyond? Transform the way you showcase your content with the efficiency and professionalism of perfect binding machines. Take the next step in enhancing the quality and durability of your printed materials. Explore our range of perfect binding solutions today and invest in the tools that will set your business apart. Contact us today to discuss how our perfect binding solutions can meet your unique needs.