What is Thermal Binding?

Thermal binding is a popular document finishing method used to create professional-looking books and reports without the need for punching holes or using mechanical fasteners. This technique relies on heat to activate a pre-applied glue inside a binding cover, which securely holds the pages in place. Corporate, educational, and professional settings widely use it when a clean, polished presentation is important. Understanding how thermal binding works, its benefits, and where it’s best applied can help individuals and businesses choose the right binding method for their needs.

How Thermal Binding Works

Thermal binding uses a specially designed cover that has a spine pre-coated with a heat-activated adhesive. The process involves placing loose sheets of paper into the cover, aligning them properly, and then inserting the entire document into a thermal binding machine. The machine heats the spine to melt the adhesive, which then seeps into the paper edges. After a brief cooling period, the glue hardens, locking the pages in place and creating a secure, permanent bind.

Most thermal binding machines are designed to work with standard thermal binding covers, which are available in various sizes and thicknesses. Some machines can bind multiple documents at once, making them efficient for office environments with higher volume needs.

Thermal binding differs from other types of binding methods, like comb, wire, or spiral binding, in that it uses heat-activated glue to secure pages within a cover, creating a clean, book-like spine without punching holes. While methods like comb or spiral allow documents to lie flat and be edited easily, thermal binding offers a more polished, permanent finish ideal for reports, proposals, and books.

Types of Thermal Binding Covers

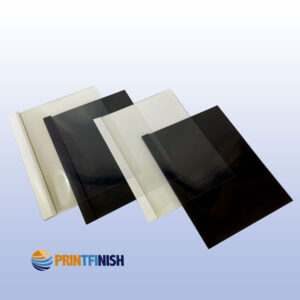

Thermal binding covers come in several formats:

- Clear front covers with solid back covers – Often used for presentations and reports, these provide a professional look while allowing the title page to be visible.

- Hardcovers – Used for books, manuals, or high-end presentations, they offer a more durable and formal appearance.

- Softcovers – Suitable for everyday reports or manuals, providing flexibility and a polished finish.

The spine width of the cover must match the document thickness for a secure bind. Manufacturers typically offer covers to fit a range of document sizes, usually up to 500 sheets.

6 Advantages of Thermal Binding

Thermal binding offers several advantages that make it an appealing choice for many users:

- Professional Appearance – The smooth, glue-bound spine gives documents a clean, book-like finish. It’s ideal for reports, proposals, manuals, and self-published books.

- No Hole Punching Required – Unlike comb or wire binding, thermal binding does not require punching holes through the paper, preserving the integrity of the pages.

- Time Efficiency – Thermal binding machines are fast and easy to use, often requiring less manual effort than mechanical binding systems.

- Batch Processing – Some machines can bind several books at once, improving productivity in office settings.

- Durability – Once cooled, the adhesive forms a strong bond that holds up well under regular use, provided the correct spine size is used.

- Customizability – Thermal binding covers can be branded or printed with logos, titles, and graphics, offering great flexibility for corporate identity or presentation purposes.

Limitations of Thermal Binding

While thermal binding is efficient and attractive, it does come with a few limitations:

- Once a document is bound, it’s difficult to add or remove pages without reheating and potentially damaging the spine.

- For a neat finish, pages must be properly aligned in the cover before binding. Misalignment can lead to uneven results.

- Users must use the correct spine width for the number of pages; using the wrong size may lead to weak binding or glue overflow.

- Unlike spiral or comb binding, thermal-bound documents do not lie flat when opened, which can be inconvenient for some uses, such as manuals or notebooks.

Common Uses of Thermal Binding

Thermal binding is ideal for a variety of applications across multiple industries. Some common uses include:

- Business Reports and Proposals – Impress clients and stakeholders with polished, professionally bound documents.

- Educational Materials – Universities and schools often use thermal binding for theses, dissertations, and coursework.

- Self-Publishing – Authors and creators can use thermal binding for small runs of books or booklets without the expense of professional bookbinding services.

- Instruction Manuals – Companies often use thermal binding for product manuals and training materials due to its clean look and durability.

- Marketing Collateral – Presentations, catalogues, and promotional booklets can be enhanced with thermal binding to make a lasting impression.

Choosing the Right Thermal Binding Machine

When choosing a thermal binding machine, it’s important to consider the binding capacity. Think about how many pages and how many documents you typically need to bind at one time. Selecting a machine that matches your usual workload will ensure efficiency and prevent overuse or limitations during busy periods.

Another factor is the heating time. Different machines vary in how quickly they heat up and complete a binding cycle. If you’re in a fast-paced environment, a machine with a short warm-up and binding time can help you stay productive.

Cooling features also play a role in the overall binding process. Some thermal binding machines come with built-in cooling racks or trays that allow documents to cool properly after binding, helping to set the glue and preserve the quality of the bind.

The user interface of the machine can affect ease of use. Basic models may have manual controls, while more advanced ones offer digital displays, automatic timers, and safety features like auto shut-off, which can be beneficial for frequent use.

Lastly, consider the size and portability of the machine. A compact model is ideal if space is limited or if the machine needs to be moved frequently. A larger, more robust unit may be the better choice for higher-volume needs or dedicated print areas.

Best Thermal Binding Machine

The Thermal Binding Machine – TB-200 stands out as one of the best thermal binding options in 2025, offering fast, reliable, and professional document finishing for offices, schools, and print shops. The TB-200 offers quick, user-friendly binding and fits various cover sizes, making it ideal for efficient, high-quality results.

Maintenance and Care

Thermal binding machines are generally low-maintenance, but regular care is essential to keep them running efficiently. Regularly clean the glue tray and heating element to prevent buildup and maintain performance.

It’s also important to avoid overloading the machine or using covers that aren’t compatible with your specific model. Doing so can strain the machine and lead to poor binding results.

Store thermal binding covers in a cool, dry place. This helps maintain the quality of the adhesive inside the covers, ensuring a strong, secure bind when used.

With routine checks and proper maintenance, your thermal binding machine will perform consistently and last longer, saving time and money in the long run.

Thermal binding provides a simple, professional way to create sleek documents without punching or complex setups. Its speed, ease, and clean finish make it ideal for offices, schools, and small publishers. Despite some limitations, it excels in presentation and efficiency. Whether for proposals, theses, or books, thermal binding ensures consistent, polished results.

Are you a business owner seeking to enhance your document organization and presentation capabilities? Consider the efficiency and professionalism that comb binding machines can bring to your operations. Contact us today to explore a range of comb binding solutions tailored to your specific needs, and elevate the way you present documents in your business.