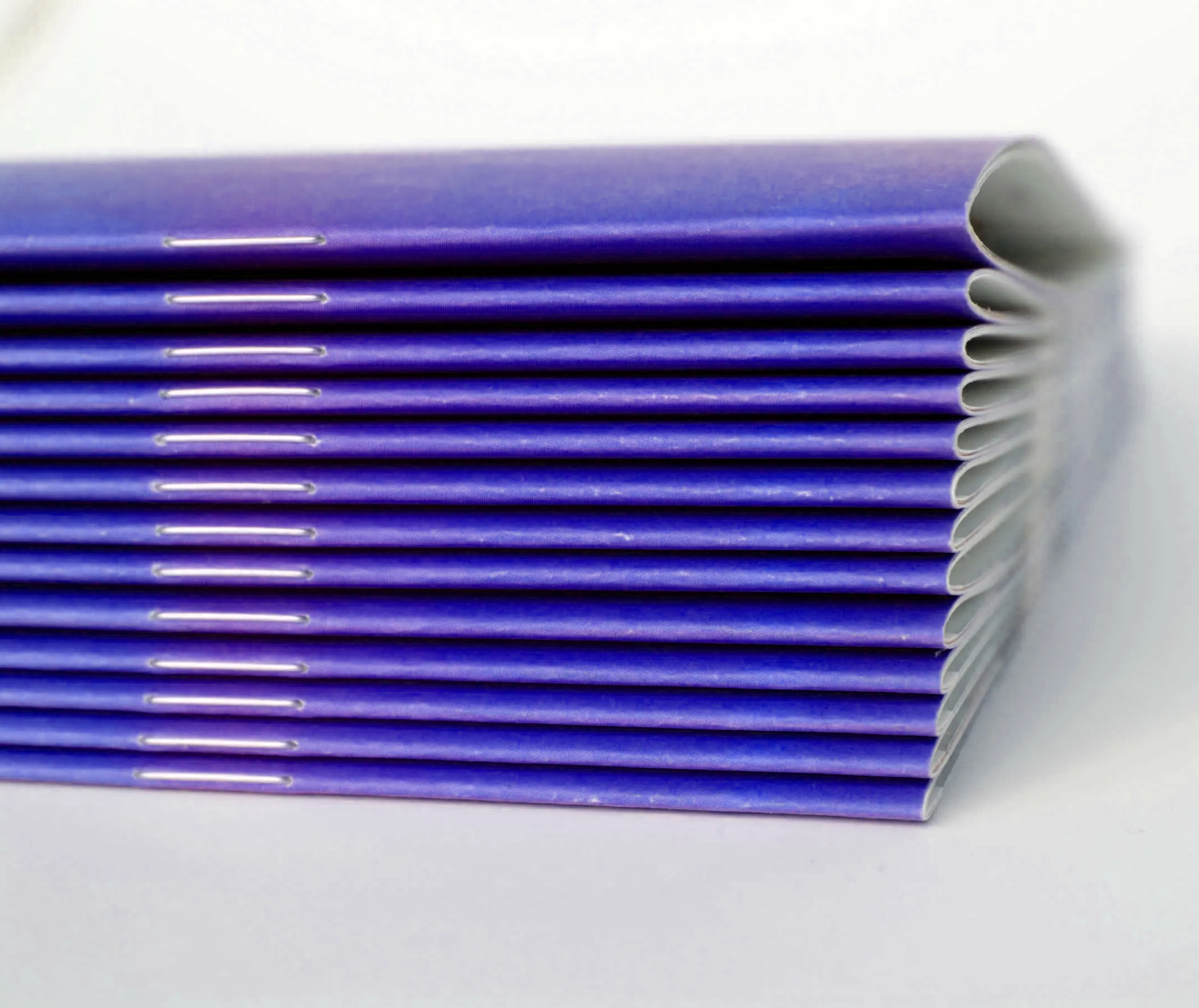

Tag: saddle stitching

10 Most FAQs About Saddle Stitching

Curious about saddle stitching? In this article, we’ll delve into the world of saddle stitching, addressing frequently asked questions and understanding this popular binding method. Whether you’re a seasoned print professional or a newcomer to the industry, understanding the ins and outs of saddle stitching is crucial for producing high-quality booklets, brochures, magazines, and more. From its process and benefits to common concerns and troubleshooting tips, we’ve got you covered. So, let’s saddle up and explore everything you need to know about saddle stitching.

1. What is Saddle Stitching?

Saddle stitching is a popular binding method used to assemble booklets, brochures, magazines, and other printed materials. In this process, folded sheets are gathered together and stapled along the fold line, creating a spineless binding. The term “saddle stitching” originates from the method of placing the folded sheets over a saddle-like apparatus during the stapling process. This simple yet effective technique is widely utilized due to its cost-effectiveness, quick production turnaround, and suitability for a wide range of print projects. Saddle stitching produces professional-looking publications with a flat opening, making it easy for readers to view the content seamlessly across pages.

2. Are there Different Types of Saddle Stitching?

Saddle-stitched books can be categorized into two types: “Self-Cover” and “Plus Cover.”

A Self-Cover book utilizes the same type and weight of paper for both the outer cover and the interior pages, resulting in the entire book, cover, and pages, being printed on identical paper. This approach offers cost savings as it eliminates the need for separate production runs for the cover and pages.

On the other hand, a Plus Cover book features a distinct paper type for the cover compared to the interior pages. Typically, a Plus Cover book uses a heavier paper for the cover and a lighter paper for the pages. Additionally, it’s common for the cover to have a coated stock while the inside pages remain uncoated. In both instances, the paper stock for the cover differs from that of the pages, hence earning the designation “Plus Cover” books.

3. Minimum Page Counts for Saddle Stitching

The minimum page count for saddle stitching typically depends on factors such as the thickness of the paper used and the binding equipment’s capabilities. However, a common rule of thumb is that saddle stitching is most effective for booklets with minimum page counts of 8 pages. Booklets with fewer than 8 pages may not provide enough surface area for stable stapling.

4. Maximum Page Counts for Saddle Stitching

The maximum page count for saddle stitching depends on various factors such as the thickness of the paper, the capabilities of the binding equipment, and the desired quality of the finished product. However, as a general guideline, saddle stitching is typically suitable for booklets with page counts ranging from 64 to 100 pages.

Beyond this range, the spine of the booklet may become too bulky, causing it not to lie flat or compromising the integrity of the staples. For thicker publications, alternative binding methods such as perfect binding or spiral binding may be more appropriate to ensure a professional finish and durability. It’s advisable to consult with your printing provider or equipment manufacturer to determine the maximum page count feasible for saddle stitching based on your specific project requirements.

It’s essential to consult with your printing provider or equipment manufacturer to determine the optimal page count for your specific project and materials.

5. Can You Use Saddle Stitching for Landscape Books?

Yes, saddle stitching can be used for landscape-oriented books, although there are some considerations to keep in mind. Since saddle stitching typically involves stapling along the spine of the booklet, the orientation of the pages may affect the stability of the binding. In landscape-oriented books, the spine is typically along the shorter edge of the pages, which may result in less surface area for stapling compared to portrait-oriented books.

To ensure the stability of saddle stitching for landscape books, it’s important to adjust the placement of the staples accordingly. Additionally, using a thicker paper stock for the cover and interior pages can provide additional support and stability to the binding. Consulting with your printing provider or equipment manufacturer can help determine the best approach for saddle stitching landscape-oriented books based on your specific project requirements.

6. Can You Include Printed Text on the Spine for Saddle Stitched Books?

As saddle-stitched books are formed by folding sheets, the resulting spine is essentially a narrow folded edge. Due to this structure, there is no space available on the spine for printing.

7. What Types of Books/Projects Can Be Saddle Stitched?

Saddle stitching is a versatile binding method suitable for various types of books and projects. Common examples include:

- Booklets and brochures: Saddle stitching is ideal for producing booklets, brochures, pamphlets, and catalogues, especially those with a moderate page count.

- Magazines and newsletters: Many magazines and newsletters are saddle stitched due to its cost-effectiveness and ability to lay flat when opened, providing ease of reading.

- Programs and guides: Programs for events such as weddings, concerts, or conferences, as well as instructional guides and manuals, can benefit from saddle stitching for a professional finish.

- Comics and zines: Saddle stitching is often used for smaller publications such as comics, zines, and chapbooks, providing a simple yet effective binding method.

- Calendars and planners: Saddle stitching is commonly used for calendars and planners, allowing them to lay flat when open for easy viewing and organization.

These are just a few examples, but in general, saddle stitching is suitable for projects with moderate page counts that require a professional finish and the ability to lay flat when opened.

8. Main Benefits of Saddle Stitching

The main benefits of saddle stitching include:

- Cost-effectiveness: Saddle stitching is a relatively inexpensive binding method, making it an economical choice for projects with moderate page counts.

- Lay-flat capability: Saddle-stitched books lay flat when opened, allowing for easy viewing and reading without the pages flipping shut.

- Quick production turnaround: Saddle stitching is a fast and efficient binding method, resulting in shorter production times compared to other binding methods.

- Versatility: Saddle stitching can accommodate a wide range of paper sizes and types, as well as various project types such as booklets, brochures, magazines, and more.

- Professional appearance: Saddle-stitched books have a clean and professional appearance, making them suitable for a variety of applications including marketing materials, instructional guides, and event programs.

Overall, saddle stitching offers a combination of affordability, functionality, and versatility, making it a popular choice for many printing projects.

9. Best Machine for Saddle Stitching

Here are some of the best saddle stitching machines:

- Sysform 106E Electric Stapler Flat Saddle

- Salco Rapid 106 R106E Electric Stapler

- DeLuxe Book Stitchers M17-AST

- MBM stitchmaster wire stitcher

- BM-35 Tabletop Booklet Maker with Square Back Feature

- SQ-70 Square Back Maker

10. Is Saddle Stitching Affordable?

Yes, saddle stitching is generally considered to be an affordable binding method. Compared to other binding techniques such as perfect binding or hardcover binding, saddle stitching typically requires less labor and materials, resulting in lower production costs. Additionally, saddle stitching is well-suited for projects with moderate page counts, making it a cost-effective choice for booklets, brochures, magazines, and other printed materials.

However, the cost of saddle stitching can vary depending on factors such as the size of the project, the complexity of the design, the type of paper used, and the printing provider’s pricing structure. It’s always a good idea to obtain quotes from multiple printing providers to ensure you’re getting the best value for your specific project requirements.

Are you a business owner in search of reliable saddle stitching machines to streamline your document-binding needs? Look no further. Contact us now to find the ideal coil binding machine that meets your specific requirements and witness the difference it can make for your business.