Tag: guide for printing business

How to Start a Digital Printing Business

In the digital age, personalized and on-demand printing is more in demand than ever before. From business cards and brochures to custom T-shirts, mugs, and banners, digital printing services are sought by businesses, events, and individuals alike. Starting a digital printing business can be a profitable venture, provided you plan wisely and execute effectively. Here’s a comprehensive guide to help you get started.

What is Digital Printing

Digital printing is a modern method of printing that transfers digital images directly onto various media surfaces without the need for traditional printing plates. Unlike offset printing, which involves a more complex setup, digital printing uses advanced inkjet or laser printers to produce high-quality prints quickly and efficiently. This technology is ideal for short runs, customized designs, and on-demand production, making it popular for printing everything from business cards and flyers to custom apparel, packaging, and promotional materials. Its speed, flexibility, and cost-effectiveness make digital printing a cornerstone of today’s print industry.

Key Steps to Launch Your Digital Printing Business

Starting a digital printing business requires more than just owning a printer—it involves thoughtful planning, the right equipment, and a clear strategy. Before diving into production, it’s important to lay a strong foundation by understanding your market, defining your services, and preparing your workspace and materials. Here are the essential steps to help you get started on the right foot.

1. Understand the Market

Before diving in, it’s essential to understand the digital printing industry. Research current trends, target audiences, and key service demands in your area. Are local businesses in need of marketing materials? Is there a market for custom apparel or merchandise? Will you cater to walk-in customers, businesses, or online shoppers?

Identify your niche early—corporate branding, event merchandise, personalized gifts, or marketing materials. Choosing a niche allows you to tailor your services and marketing strategies effectively.

2. Create a Business Plan

Every successful business starts with a solid plan. Your digital printing business plan should cover:

- Business name and structure (sole proprietorship, LLC, etc.)

- Services offered (e.g., T-shirt printing, flyers, posters, banners)

- Target market

- Pricing strategy

- Startup and operating costs

- Marketing and sales strategies

- Revenue projections

A clear plan helps secure financing, keeps you focused, and guides your business development.

3. Choose the Right Equipment

Your equipment determines your service range and quality. Here are the common tools and machines you’ll need:

- Digital printers (inkjet or laser for paper materials)

- DTG (Direct-to-Garment) printer for custom apparel

- Heat press machine for transfer printing

- Cutting machines for stickers and decals

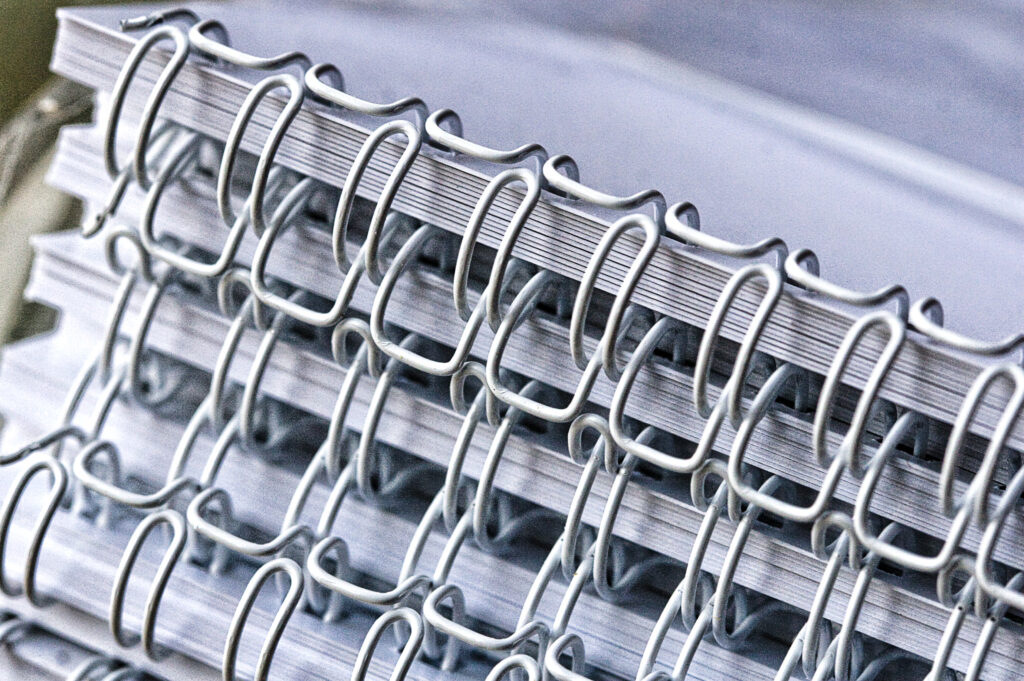

- Laminators and binding machines for finishing services

- A computer with design software like Adobe Illustrator or CorelDRAW

Invest in reliable, scalable equipment. If budget is a concern, consider buying refurbished machines or starting with a narrower range of services.

4. Set Up Your Workspace

Depending on your business model, you may work from a home studio, small office, or storefront. Your space should be:

- Well-ventilated, especially when using inks and heat presses

- Organized, with designated areas for printing, finishing, and packaging

- Accessible, if you plan to accept walk-in customers

Ensure you comply with local zoning and safety regulations, and get any necessary permits.

5. Source Quality Materials

The quality of your prints depends on the materials you use—paper, fabric, ink, and substrates. Work with reputable suppliers to ensure consistency. Some factors to consider:

- Paper weight and finish (glossy, matte, etc.)

- Ink compatibility with printers

- Fabric quality for apparel

- Specialty materials like vinyl, canvas, or plastic

Buy in bulk for cost efficiency, but test samples first to ensure compatibility with your equipment.

6. Build an Online Presence

In today’s market, having an online presence is essential. Develop a professional website where customers can view products, request quotes, and place orders. Include:

- A portfolio of past work

- Service descriptions

- An online store if offering e-commerce

- Contact details and customer service information

Social media is another powerful tool. Use platforms like Instagram, Facebook, and TikTok to showcase your work, share behind-the-scenes content, and engage with potential clients.

7. Market Your Services

Effective marketing can make or break a new business. Combine online and offline strategies:

- Local SEO and Google My Business listings

- Flyers and brochures for nearby businesses

- Email marketing to build customer loyalty

- Referral programs to encourage word-of-mouth

- Networking at trade shows, fairs, and business events

Tailor your marketing to your niche. If you’re targeting small businesses, emphasize fast turnaround, branding consistency, and bulk discounts.

8. Offer Excellent Customer Service

Customer satisfaction leads to repeat business and referrals. Ensure:

- Clear communication during order taking

- Timely delivery and accurate prints

- Responsive customer support

- Flexible customization options

Consider offering free design templates or small add-ons to enhance perceived value.

9. Keep Learning and Innovating

The digital printing industry evolves rapidly. Stay updated with:

- New printing technologies

- Design trends and colour theory

- Software updates

- Sustainability practices like eco-friendly inks and papers

Take feedback seriously and look for opportunities to improve. Innovation helps you stay ahead of the competition.

10. Scale at Your Own Pace

Once your business is running smoothly, explore ways to expand:

- Add new services like embroidery, laser engraving, or large-format printing

- Offer design services or partner with freelance designers

- Hire staff to increase output and customer handling

- Open additional locations or expand online

Make sure growth aligns with customer demand and your capacity to deliver quality consistently.

Starting a digital printing business combines creativity, technology, and entrepreneurship. With the right equipment, planning, and dedication, you can build a successful business that caters to a wide range of personal and professional printing needs. Focus on quality, stay customer-oriented, and continue learning to thrive in this dynamic industry.

Are you seeking cutting-edge digital printers that combine speed, precision, and versatility to meet the demands of today’s dynamic market? Look no further. Explore our range of state-of-the-art digital printers that promise not just efficiency but a transformative printing experience. Contact us today and discover how our advanced solutions can take your business to new heights.