Tag: print finish

Introducing Roland VersaSTUDIO BD-12 UV Flatbed Printer

UV printing has become a vital solution for businesses seeking to enhance their visual presence with high-quality graphics on a wide range of surfaces. Flatbed printers, in particular, offer the flexibility to print directly onto objects of different shapes, sizes, and materials, making them ideal for custom products, signage, packaging, and more. As demand continues to grow for compact, user-friendly UV printing solutions, Roland DG responds with the latest addition to its expanding lineup in the BD Series.

Roland DG remains a trusted name in flatbed printing, known for delivering high-quality, reliable solutions that meet the needs of businesses across a wide range of industries. With a strong track record of innovation and precision, their printers are valued for their exceptional performance, versatility, and consistent print quality. As the company expands its lineup once again, it reinforces its position as a leader in flatbed printing technology.

What is a UV Flatbed Printer

A UV flatbed printer is a type of digital printer that uses ultraviolet (UV) light to instantly cure or dry specially formulated UV inks as they are printed directly onto the surface of various materials. Unlike traditional printers, a flatbed UV printer features a stationary, flat printing bed that accommodates a wide range of rigid and flexible substrates such as plastic, wood, metal, glass, leather, and acrylic. This technology allows for high-resolution, full-colour printing with excellent durability and adhesion, making it ideal for producing customized promotional items, signage, packaging prototypes, and industrial parts with sharp detail and vibrant colour.

Roland VersaSTUDIO BD-12 UV Flatbed Printer

The demand for compact, versatile printing solutions continues to grow, especially among small businesses, retailers, and creators looking to add value through customization. Roland DG addresses this need with the introduction of the VersaSTUDIO BD-12—an easy-to-use UV flatbed printer that brings professional-quality results to desktops and small workspaces. Designed to handle a wide range of applications, the BD-12 makes it simple to create vibrant, detailed prints directly onto various objects or through UV DTF transfers, opening new possibilities for on-demand personalization.

Notable Features:

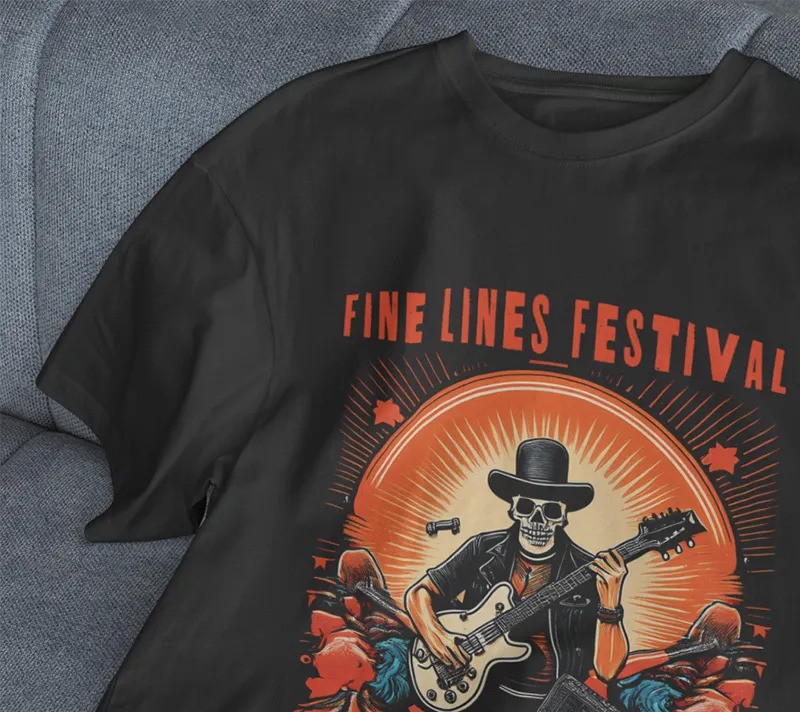

- 3D Object Customization – Enables high-margin personalization on a wide variety of in-demand products.

- Professional-Quality Output – Produces sharp, vibrant prints that meet industry standards and exceed customer expectations.

- User-Friendly Operation – Simplifies production and minimizes training time, making it accessible even to first-time users.

- Space-Saving Design – Compact form factor fits easily in home offices, studios, or retail spaces with limited room.

- Built-In Safety Features – Designed for safe use in shared or enclosed environments, ensuring peace of mind during operation.

- Entry-Level Affordability – Offers new businesses a cost-effective way to start printing and earning right away.

Where Creativity Meets Opportunity

Bringing your ideas to life is easier than ever with the BD Series. These printers allow you to print vivid graphics and crisp text directly onto 3D objects, making it simple to personalize products for customers or create custom-branded items for your business. Whether you’re starting a side hustle or building a full product line, the BD Series helps turn your creativity into profit.

Designed to Fit a Variety of Users and Applications

The BD Series is built to support a range of creative and business needs, making it an ideal choice for different users and environments.

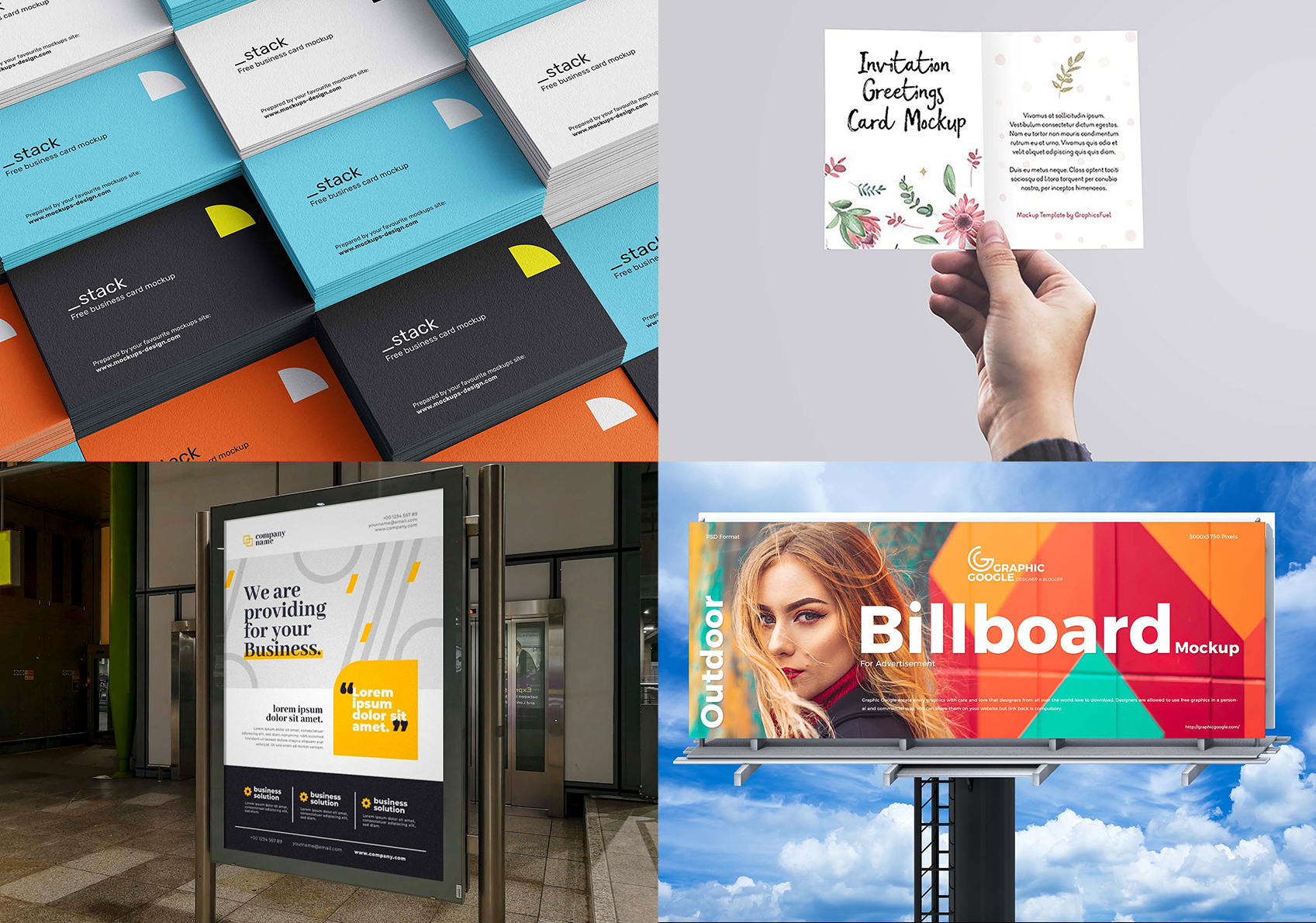

- Perfect for Retailers – Expand your offerings with a wide range of customized, branded products that create new revenue opportunities.

- Ideal for Makers & Small Businesses – Easily craft unique, personalized items tailored to your customers or to represent your brand.

- Great for Educators – An excellent hands-on learning tool that helps bring creative concepts to life through real-world design applications.

Versatile Printing on a Wide Range of Surfaces

The BD Series offers exceptional material compatibility, giving users the flexibility to print high-quality designs on many different types of surfaces and objects.

- Print on a Variety of Materials – Compatible with plastics, paper, leather, wood, and more—even glass and metal with the use of onboard primer ink.

- Handles Complex Surfaces – Easily print on convex, concave, and irregular surfaces with precision.

- Supports 3D Object Printing – Ideal for adding graphics to curved or uniquely shaped items.

- Create Gloss Effects – Add eye-catching gloss finishes to enhance texture and visual appeal.

- Works on Textured Surfaces – Achieve sharp, vibrant results even on uneven or textured materials.

- Multi-Surface Capability – Confidently print on glass, wood, metal, plastic, and a wide range of other substrates.

More Key Features of the BD Series

The BD Series offers a range of standout capabilities that combine professional performance, ease of use, and space-saving design—ideal for creative entrepreneurs, educators, and small businesses.

UV DTF Printing Capabilities

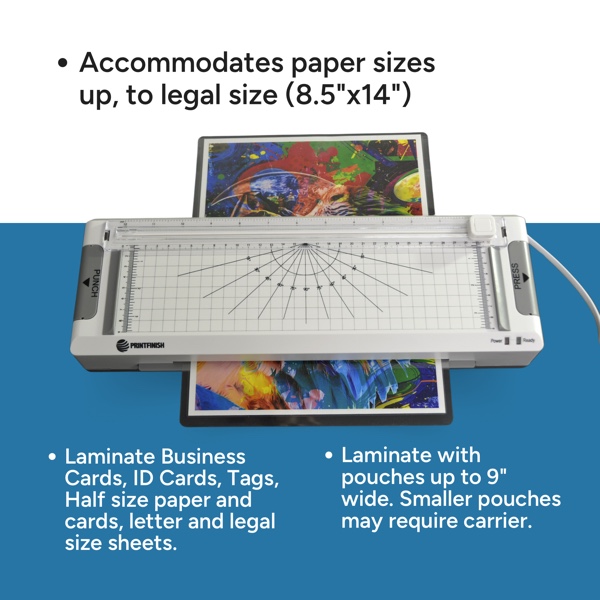

Easily produce UV DTF decals for applying detailed designs to various surfaces and shapes without weeding. Perfect for customizing plastics, metal, wood, acrylic, glass, and more with vibrant prints for items like tech gadgets, accessories, and event merchandise.

Professional Results Made Simple

Achieve sharp, vibrant output with ease using True Rich Colour settings and a range of print modes optimized for different surfaces—no prior print experience required.

Print Light Colours on Dark Surfaces

White ink support allows for bright, opaque designs on dark materials, while onboard Primer ink enables reliable printing on textured surfaces like glass and metal.

High Performance, Compact Size

With a desktop-friendly design and front-access operation, BD Series printers save space and fit seamlessly into tight work areas. Built-in fume extraction, GREENGUARD Gold certified inks, and a protective UV light cover ensure safe and clean operation.

Affordable and Scalable

Designed with startups and small businesses in mind, BD Series printers offer professional output at a budget-friendly price. They include user-friendly design and output software, and a built-in fume extractor eliminates the need for costly external systems.

Rotary Printing Option

Expand your capabilities with an optional rotary accessory that enables 360° printing on round or curved objects up to 2 inches in diameter, such as pens, jars, and small bottles.

Simplified Maintenance

Keep your printer in top condition with automatic printhead cleaning and intuitive maintenance tools. The BD Series is ready to use right out of the box, with responsive support just a click or call away.

The Roland VersaSTUDIO BD Series offers an ideal combination of professional-grade print quality, user-friendly features, and space-saving design—making it the perfect choice for small businesses, creatives, educators, and entrepreneurs looking to expand their product offerings. With its ability to print on a wide variety of materials and objects, along with options like UV DTF and rotary printing, the BD Series opens up endless possibilities for customization. Whether you’re starting out or scaling up, the BD Series provides the tools, flexibility, and reliability you need to grow your business with confidence.

If you are a potential business owner looking to print promotional products, PRINTFINISH is your ultimate partner for success. Our comprehensive range of cutting-edge printing and finishing solutions, coupled with our expertise and exceptional customer support, will empower your business to thrive in the competitive market. Contact us today and unlock the full potential of your printing business with PRINTFINISH as your trusted partner.