Tag: binding tips

Benefits of Using Perfect Binding

Regarding document presentation, perfect binding emerges as a premier method, offering a seamless blend of elegance and functionality. This article delves into the intricacies of perfect binding, exploring its benefits and applications in various settings. From corporate reports to literary works, perfect binding provides a polished finish that commands attention and conveys professionalism. As we navigate the advantages of perfect binding, we’ll uncover how this technique elevates the quality of bound documents, enhances durability, and offers a sophisticated aesthetic appeal. Whether you’re a business professional, a student, or a creative enthusiast, understanding the benefits of perfect binding is essential for achieving standout results in your projects.

What is a Perfect Binding Method?

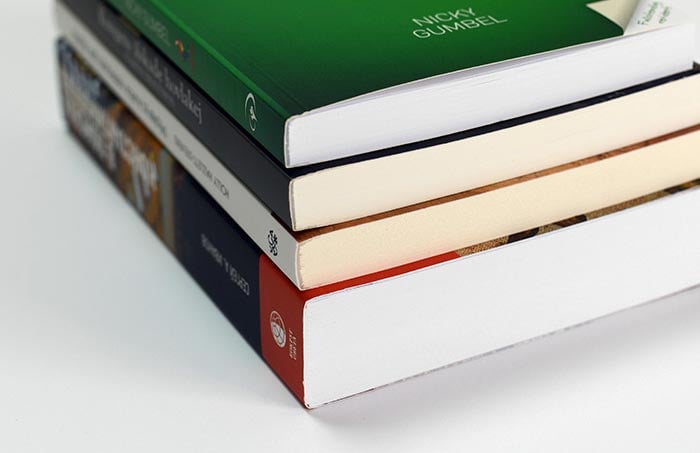

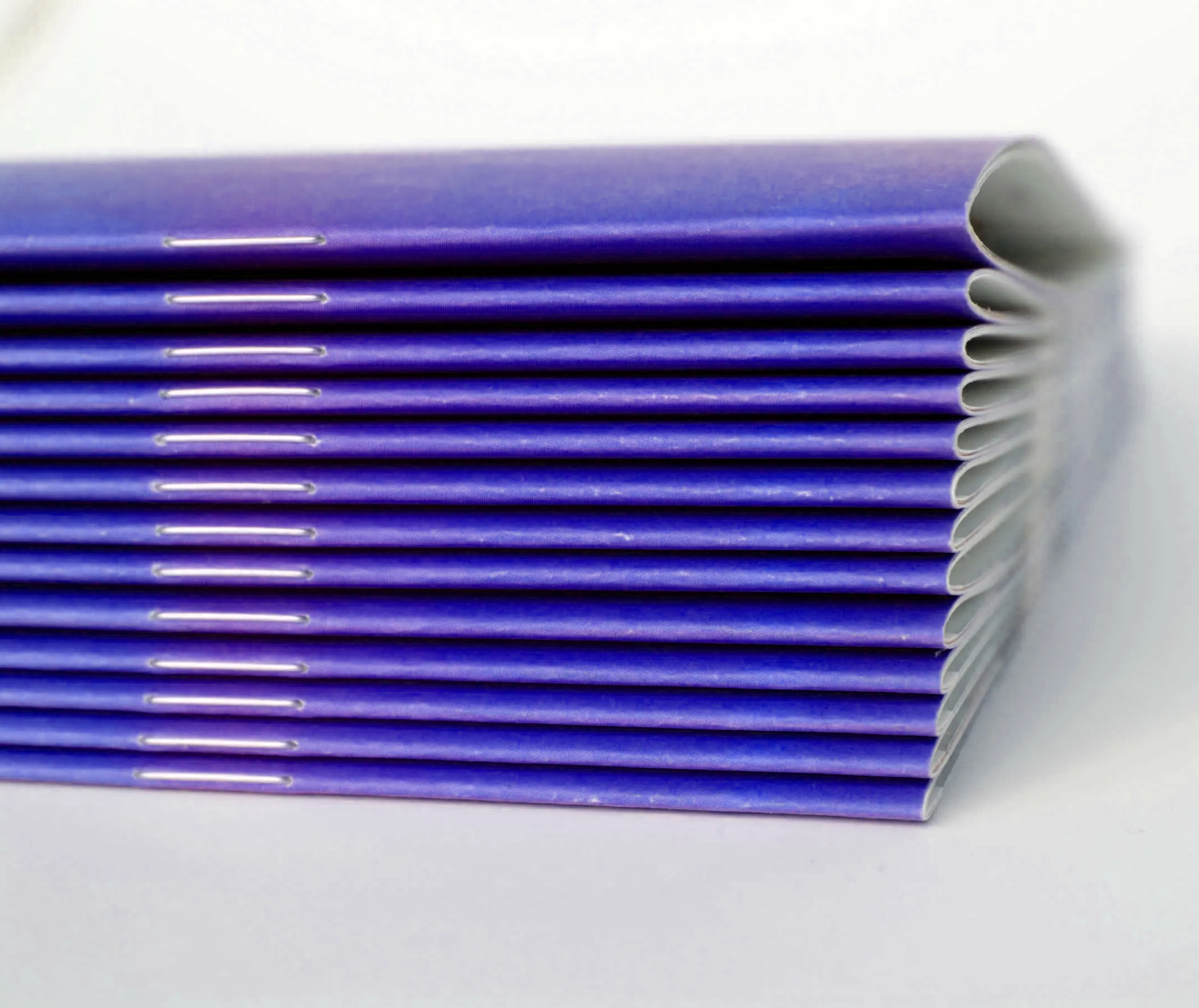

Perfect binding is a widely used bookbinding method that involves securing the pages of a document to a wrap-around cover using adhesive. This method is commonly used for paperback books, magazines, catalogues, and other publications. During the perfect binding process, the pages are stacked together and then trimmed to ensure uniform edges. A flexible adhesive is applied to the spine edge of the pages, and they are then attached to the cover, creating a seamless and professional-looking finish. Perfect binding provides a clean and polished appearance, making it a popular choice for a wide range of printed materials.

Benefits of Using Perfect Binding

Perfect binding offers several benefits that make it a popular choice for binding various types of documents:

- Professional Appearance: Perfect binding provides a clean and polished finish, giving documents a professional and upscale look. This makes it ideal for business reports, marketing materials, and publications where presentation is key.

- Durable and Long-lasting: The adhesive used in perfect binding creates a strong and durable bond between the pages and the cover, ensuring that the document withstands frequent handling and lasts longer compared to other binding methods.

- Customizable Covers: Perfect binding allows for customization of the cover design, including the use of full-color graphics, images, and text. This flexibility enables businesses to create branded materials that effectively communicate their message and identity.

- Suitable for Large Documents: Perfect binding can accommodate documents with a large number of pages, making it suitable for thick books, manuals, and catalogues. It provides a professional-looking solution for organizing and presenting extensive content.

- Lay-flat Design: Once bound, perfect-bound documents can lay flat when opened, allowing for easy reading and referencing. This feature enhances user experience and convenience, particularly for instructional manuals, textbooks, and cookbooks.

- Cost-effective for Large Print Runs: While perfect binding may have higher upfront costs compared to some other binding methods, it becomes more cost-effective for large print runs due to its efficiency in production and durability over time.

- Versatility: Perfect binding can be used for a wide range of document types, including magazines, brochures, novels, annual reports, and more. Its versatility makes it a versatile solution for various industries and applications.

Overall, perfect binding offers a combination of professional appearance, durability, customization options, and versatility, making it an excellent choice for creating high-quality bound documents.

Best Perfect Binding Machines in 2024

Here are some of the best perfect binding machines:

- Boway Perfect Binder BW-JB2

- Boway Perfect Binder BW-920V

- Sysform 50A Professional Perfect Binding Machine

- Sysform 50B Professional Perfect Binding Machine

Other Common Types of Binding Methods

Here are some other types of binding methods aside from perfect binding:

- Saddle Stitching: This method involves folding sheets of paper and stapling them together along the fold line. Saddle stitching is commonly used for booklets, brochures, and magazines.

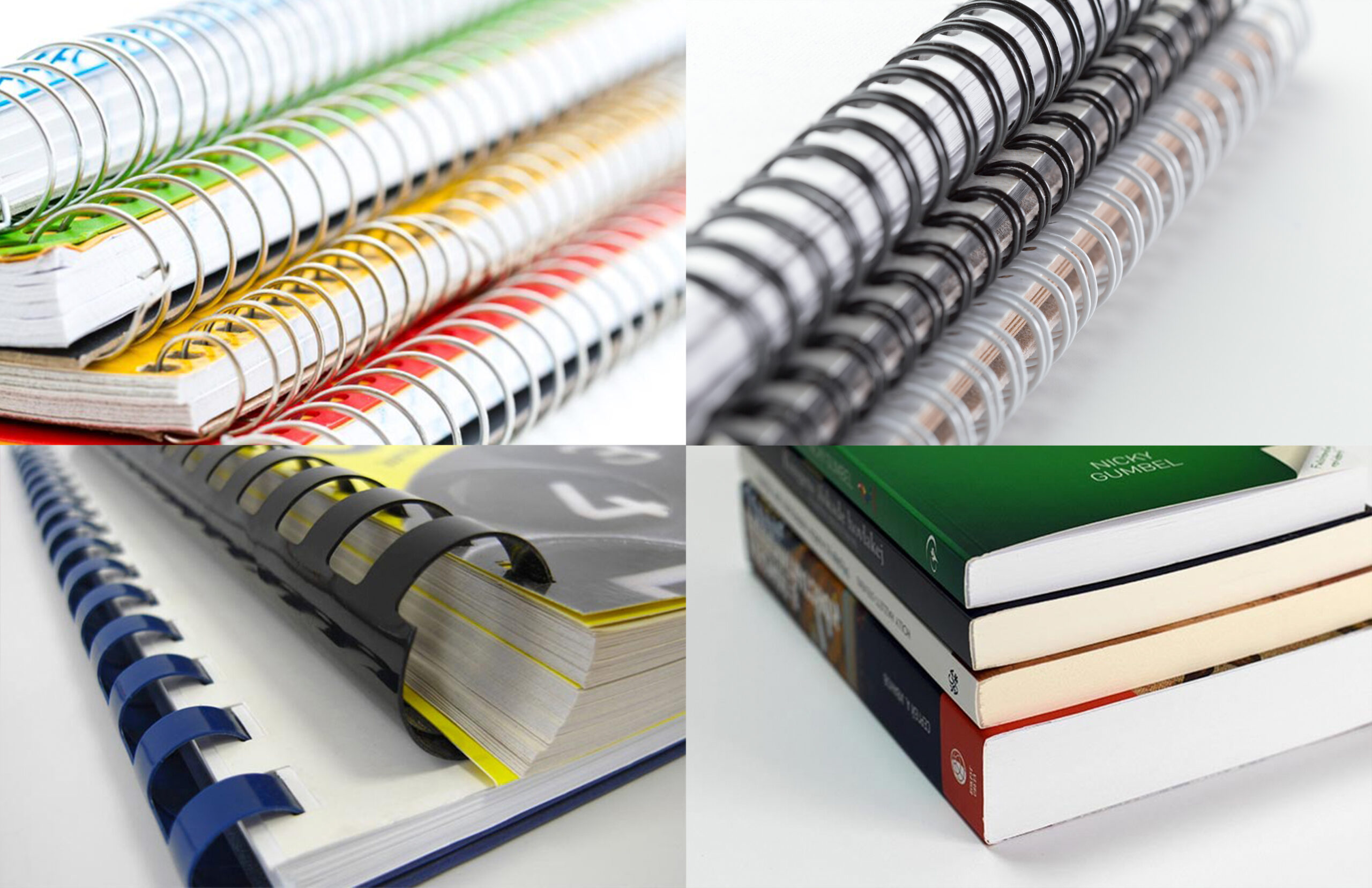

- Spiral Binding: Also known as coil binding, spiral binding uses a coil or wire to hold the pages together. This method allows the document to lay flat and is often used for notebooks, calendars, and presentations.

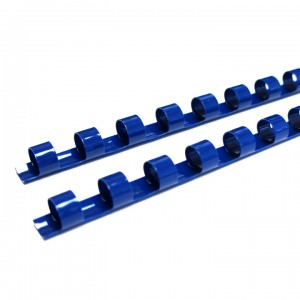

- Comb Binding: Comb binding utilizes plastic combs with teeth that fit into rectangular holes punched along the edge of the pages. It allows for easy editing by opening and closing the comb. Comb binding is popular for reports, manuals, and presentations.

- Wire-O Binding: Similar to spiral binding, Wire-O binding uses a double-loop wire to hold the pages together. It provides a more professional appearance and allows for easy page-turning. Wire-O binding is commonly used for presentations, reports, and calendars.

- Hardcover Binding: Hardcover binding involves attaching the pages to a rigid board cover. This method provides durability and a polished finish, making it suitable for books, journals, and special editions.

Each of these binding methods has its advantages and is suitable for different documents and purposes.

In conclusion, the perfect binding method stands out as a versatile and practical solution for a wide range of document binding needs. Its professional appearance, durability, and ability to accommodate large publications make it a preferred choice for businesses, publishers, and individuals alike. With customizable covers, lay-flat design, and suitability for various document types, perfect binding offers unparalleled versatility and aesthetic appeal. Whether it’s for reports, books, catalogues, or marketing materials, perfect binding ensures that documents are not only well-organized and durable but also visually impressive. Embracing the benefits of perfect binding can elevate the quality and impact of bound documents, leaving a lasting impression on readers and users alike.

Are you a business owner seeking to elevate the presentation of your publications, from catalogues to manuals and beyond? Transform the way you showcase your content with the efficiency and professionalism of perfect binding machines. Take the next step in enhancing the quality and durability of your printed materials. Explore our range of perfect binding solutions today and invest in the tools that will set your business apart. Contact us today to discuss how our perfect binding solutions can meet your unique needs.