Tag: comb binding

Binding 101: Quick Binding Tips

Regarding document management, choosing the right binding method is vital for professional presentation and efficient organization. Whether it’s for business reports, academic papers, or personal projects, mastering binding techniques can significantly improve the impact and durability of your documents. This article will explore some essential tips for common binding methods such as coil, comb, thermal, and wire binding. Understanding these techniques and implementing practical tips will enhance the quality of your bound documents and streamline your workflow, regardless of your expertise level.

Quick Overview of Different Binding Methods

Selecting the right binding method is crucial for document presentation. Here’s a brief overview of 6 common binding techniques:

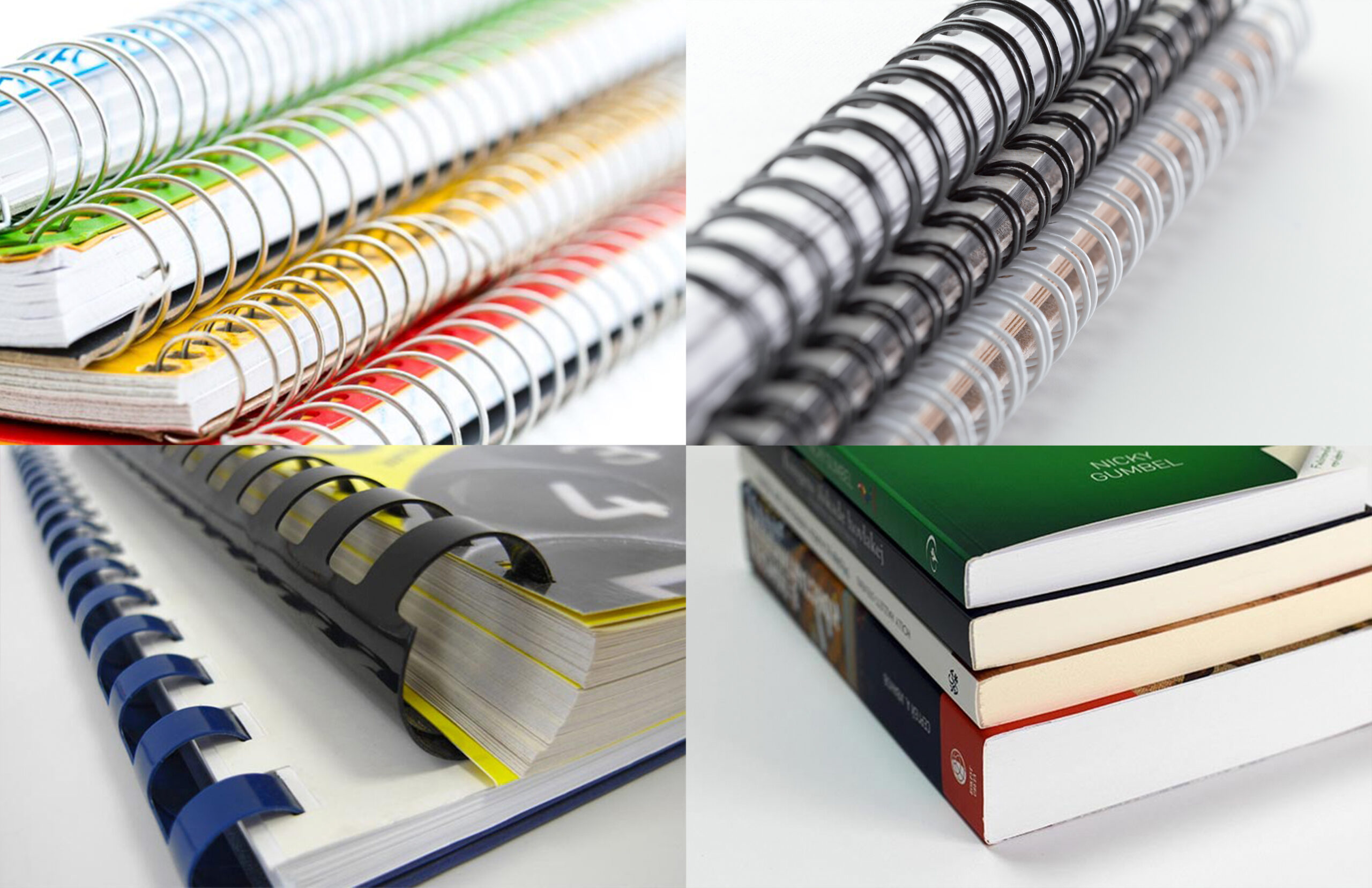

- Coil or Spiral Binding: Uses a plastic coil for documents that need to lay flat when opened.

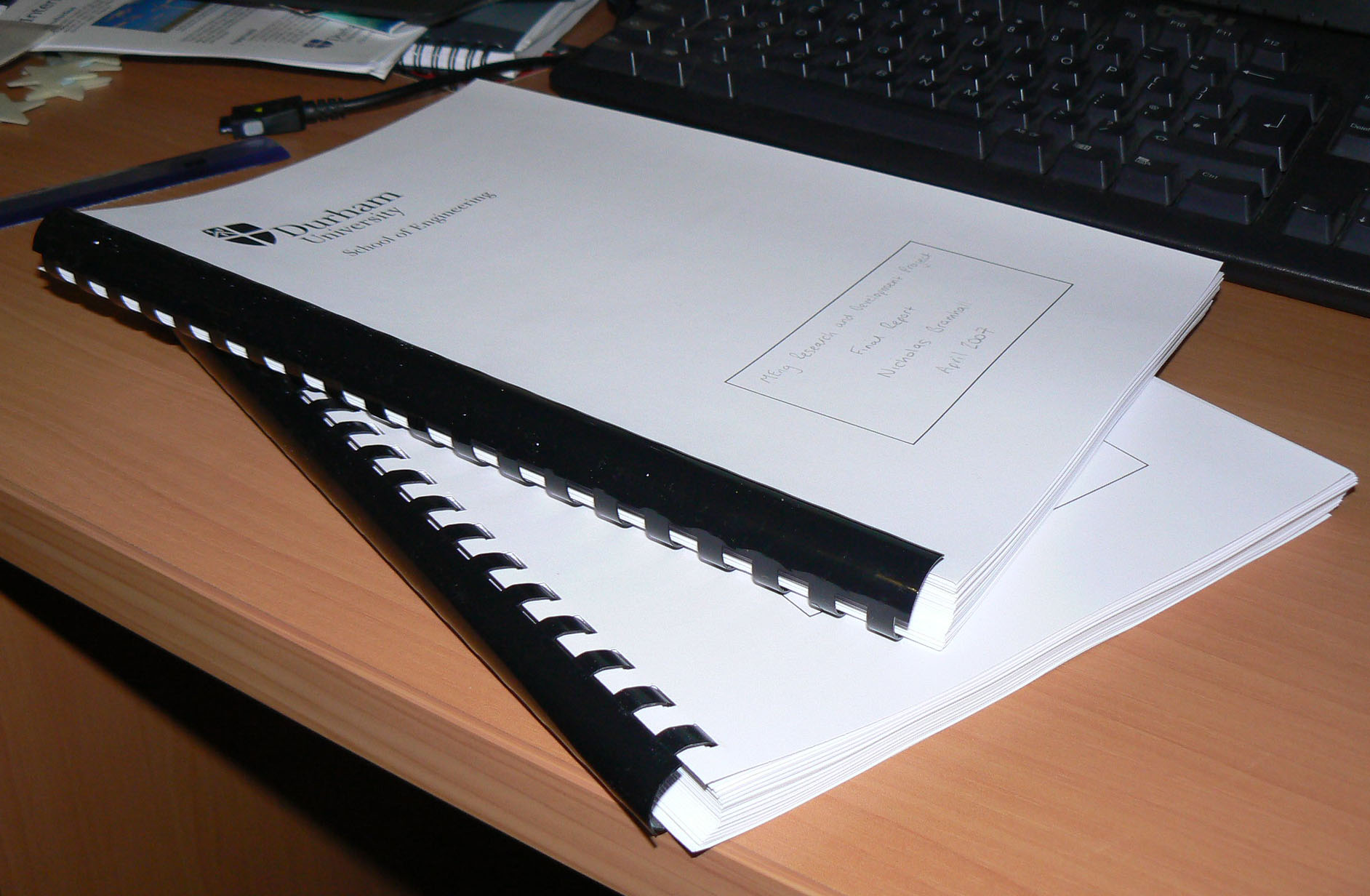

- Comb or Cerlox Binding: Offers easy editing with plastic combs and teeth to secure pages.

- Wire or Wire-O Binding: Provides durability and a professional appearance with metal wires.

- Saddle Stitching: Suitable for booklets and magazines, involves stapling sheets along the fold line.

- Perfect or Soft Cover Binding: Glues pages to a wrap-around cover, often used for paperback books.

- Case or Hard Cover Binding: Ensures durability and a polished finish with pages attached to a rigid cover, common in hardcover books and dissertations.

Understanding these methods helps you choose the best one for your document needs.

Some Binding Tips to Remember

Without further ado, here are some quick binding tips to keep in mind:

- Plan ahead: Determine the type of document, its purpose, and the number of pages before choosing a binding method.

- Prepare your materials: Organize your pages correctly and ensure they’re properly aligned before binding.

- Test your machine settings: Adjust the settings on your binding machine according to the thickness of your document to ensure a secure bind without damaging the pages.

- Leave a margin: Leave a small margin around the edges of your pages to prevent text or images from being cut off during the binding process.

- Use high-quality supplies: Invest in durable binding covers, spines, and paper to enhance the overall appearance and longevity of your bound documents.

- Practice safety precautions: Familiarize yourself with the operation of your binding machine and follow safety guidelines to avoid accidents or injuries.

- Experiment with different techniques: Explore various binding methods and techniques to find the one that best suits your needs and preferences.

- Take your time: Rushing through the binding process can lead to mistakes or uneven binds, so take your time and work carefully to achieve professional results.

- Seek guidance if needed: Don’t hesitate to consult instructional materials or seek help from experienced users if you encounter difficulties or need advice on binding techniques.

- Choose the best and most appropriate binding machine: Each binding method works best if being paired/used with the appropriate binding machine.

Best Binding Machines:

Depending on the binding methods you’ll choose, here are some of the best binding machines to consider:

Coil Binding Machine

- Akiles Duo Mac 321

A versatile and user-friendly coil binding machine, designed to streamline the binding process for businesses and organizations. With its efficient electric punching and binding capabilities, it empowers users to create professionally bound documents with ease and precision. - CoilBind S25A Spiral Coil Binding Machine

A versatile and user-friendly solution for schools and small offices. It boasts a robust punch capacity of up to 20 sheets (20# paper) and features a full handlebar that accommodates left-handed, right-handed, or two-handed operations, ensuring ease of use. - SUPU PC360E Electric Coil Binding Machine 14″

With its electric punching and binding capabilities, it streamlines the coil binding process, allowing for the efficient production of professional-quality documents and presentations.

Comb Binding Machine

- C-12 Comb Binding Machine

A heavy-duty, manual comb binding machine that’s perfect for binding letter-size, A4, A5, or smaller office documents. Its lightweight and portable design makes it an excellent addition to school or small office environments, offering convenience and versatility for document binding needs. This user-friendly machine includes plastic comb-style binder spines, making it an ideal choice for creating professionally-bound documents with ease. - Akiles Duo Mac 321

A heavy-duty, multi-functional, and user-friendly binding machine that offers both money and space-saving benefits. With the ability to perform two different types of binding in one single machine, it provides versatility and efficiency for businesses and individuals looking to streamline their document binding processes while optimizing both cost and workspace. - CombBind C20A Comb Binding Machine

Your go-to solution for creating professional presentations with a high-quality, cost-effective alternative. This user-friendly machine can bind documents up to 2 inches thick (approximately 425 sheets) and can punch up to 20 sheets at once, making it the ideal choice for binding letter-size pages or smaller documents, perfect for

Wire Binding Machine

- WireBind W20A Wire Binding Machine

- Supu CW430E Electric Wire-o Punching Machine with Manual Closer

- WireMac-E31 Akiles Electric Punch Manual Wire

- Akiles WBM532 Modular Wire Binding Machine

- Akiles FlexiCloser 2 Wire Binding Machine

Perfect Binding Machine

- Boway Perfect Binder BW-JB2

- Boway Perfect Binder BW-920V

- Sysform 50A Professional Perfect Binding Machine

- Sysform 50B Professional Perfect Binding Machine

Saddle Stitching Machine

- Sysform 106E Electric Stapler Flat Saddle

- Salco Rapid 106 R106E Electric Stapler

- DeLuxe Book Stitchers M17-AST

- MBM stitchmaster wire stitcher

- BM-35 Tabletop Booklet Maker with Square Back Feature

- SQ-70 Square Back Maker

Incorporating these binding tips into your workflow can significantly improve the quality and efficiency of your document binding process. By planning ahead, preparing materials properly, and utilizing high-quality supplies, you can achieve professional results with ease. Remember to take your time, practice safety precautions, and explore different techniques to find what works best for you. Whether you’re binding reports for work, presentations for school, or personal projects, mastering these quick tips will ensure your documents are well-organized, durable, and visually appealing. With a little practice and attention to detail, you’ll become a binding pro in no time.

If you’re a business owner in the office, binding, printing or publishing industry, and you’re seeking the best binding machines to enhance your operations, look no further. Our selection of high-quality binding machines is designed to meet your specific needs. Whether you require the durability of case binding, the versatility of perfect binding, or the cost-effective benefits of saddle stitching, we have the right binding solution for you. Contact us today to explore our range of binding machines and take your business to the next level.