Tag: direct-to-garment

14 Most Frequently Asked Questions About DTG Printing

When it comes to garment printing, direct-to-garment (DTG) printing stands out as a cutting-edge technology revolutionizing the industry. In this article, we delve into the frequently asked questions (FAQs) surrounding DTG printing, exploring its intricacies, advantages, and challenges. From understanding the process itself to delving into the nuances of material compatibility and design intricacies, we aim to provide a comprehensive guide for both beginners and seasoned professionals navigating the realm of DTG printing. Join us as we unravel the mysteries and unveil the potential of this innovative printing technique.

1. What is Direct-to-Garment Printing?

Direct-to-garment (DTG) printing is a modern digital printing technique that enables high-quality, full-colour designs to be printed directly onto garments such as T-shirts, hoodies, and tote bags. Unlike traditional printing methods like screen printing, which involves creating stencils and applying layers of ink, DTG printing works more like a regular inkjet printer but on fabric.

The process involves loading the garment onto a specialized printer equipped with textile inks. The printer then directly applies the ink onto the fabric, following the digital design file provided. This allows for intricate designs, vibrant colours, and detailed graphics to be reproduced accurately and efficiently.

DTG printing is highly versatile and suitable for both small and large production runs. It offers advantages such as quick turnaround times, the ability to print complex designs with gradients and fine details, and the capability to produce custom prints without the need for setup costs or minimum order quantities.

2. DTG vs Traditional Screen Printing

DTG printing excels in producing high-quality, full-color designs with intricate details and is well-suited for small to medium production runs. On the other hand, traditional screen printing is more efficient for large production runs of simple designs and offers excellent durability and colour vibrancy. The choice between the two methods depends on factors such as design complexity, production quantity, fabric type, and budget constraints.

Fabric Compatibility:

DTG Printing: Versatile and suitable for printing on various types of fabrics, including cotton, polyester, blends, and even some specialty fabrics.

Screen Printing: Works well on cotton and other natural fabrics but may not adhere as effectively to synthetic or textured fabrics.

Durability and Feel:

DTG Printing: Provides a soft feel and good durability when proper printing techniques and quality inks are used. The print becomes part of the fabric, resulting in a smooth finish.

Screen Printing: Offers excellent durability and vibrant colours. The ink sits on top of the fabric, providing a slightly raised texture and a more durable finish.

Complexity of Designs:

DTG Printing: Ideal for intricate designs, photographs, and designs with multiple colours and gradients. DTG printers can reproduce fine details accurately.

Screen Printing: Best suited for simple designs with fewer colours. Each colour in a design requires a separate screen, making it less efficient for complex designs.

3. Why Use DTG?

The combination of high-quality prints, versatility, quick turnaround times, and cost-effectiveness for small runs makes DTG printing a valuable tool for businesses, designers, and individuals seeking efficient and customizable garment decoration solutions.

4. Difference Between DTG and DTF Printing

DTG (Direct-to-Garment) printing and DTF (Direct-to-Film) printing are two distinct digital printing methods for garments. DTG printing involves directly printing ink onto fabric, resulting in vibrant, high-quality prints with intricate details and smooth gradients. On the other hand, DTF printing transfers a design from a film onto a garment using a heat press, allowing for printing on various fabrics, including cotton, polyester, and blends. While DTG printing is preferred for its versatility, ability to produce full-colour prints and soft feel, DTF printing offers advantages such as the ability to print on dark fabrics and textured surfaces, making it suitable for certain applications like personalized apparel and promotional items.

5. What Kinds of Graphics Can You Print with DTG Printing?

You can print nearly anything with DTG technology, ranging from portraits and logos to custom designs. The crucial factor lies in the quality of the graphic being printed. Graphics with good contrast, high resolution, and large bitmapped images reproduce exceptionally well, while vector images yield even better results! Here are some of the graphics you can print:

- Complex Designs: Intricate and detailed designs with fine lines, small text, and intricate patterns can be accurately printed using DTG technology.

- Photographic Prints: DTG printing excels at reproducing photographic images with high resolution and vibrant colours, making it suitable for printing portraits, landscapes, and other photographic artwork.

- Multicolour Designs: DTG printers can handle designs with multiple colours and gradients seamlessly, allowing for vibrant and dynamic prints without colour limitations.

- Logos and Branding: Company logos, branding elements, and promotional graphics can be printed onto garments with precision and clarity, helping businesses create branded apparel for marketing and promotional purposes.

- Artwork and Illustrations: DTG printing is ideal for printing artwork and illustrations with intricate details, bold colours, and shading, enabling artists and designers to showcase their creativity on garments.

- Text and Typography: DTG technology can print text and typography in various fonts, sizes, and styles, making it suitable for printing slogans, quotes, and custom text-based designs on garments.

- Custom and Personalized Designs: DTG printing allows for easy customization of garments with personalized designs, names, initials, and messages, making it popular for creating unique and one-of-a-kind apparel items.

6. 2 Common Terminologies to Know in DTG Printing

-

Bitmapped Images

Refers to a graphic that is composed of individual pixels, each assigned a specific colour value. These images are also known as raster images. In contrast to vector graphics, which are defined by mathematical formulas and scalable without loss of quality, bitmapped images have a fixed resolution and may lose clarity when scaled up. Common examples of bitmapped images include photographs, digital paintings, and scanned artwork. When printing with DTG technology, bitmapped images are suitable for achieving detailed and realistic prints, especially when they have high resolution and good contrast. All scanned images are bitmaps, and all images from digital cameras are bitmaps. Common bitmap formats include bmp, jpg, tiff, gif, png, and psd.

-

Vector Images

Graphics are created using mathematical formulas to define lines, shapes, and colors. Unlike bitmapped images, which are composed of pixels and have a fixed resolution, vector images are resolution-independent, meaning they can be scaled to any size without loss of quality. Common file formats for vector images include SVG (Scalable Vector Graphics), AI (Adobe Illustrator), and EPS (Encapsulated PostScript). Vector images are highly versatile and suitable for DTG printing because they allow for crisp, clean lines and shapes, making them ideal for logos, text, and graphics with solid colours and well-defined edges. Additionally, vector images typically result in smaller file sizes compared to bitmapped images, making them easier to manage and manipulate. Common vector formats include cdr (CorelDRAW), ai (Adobe Illustrator) and eps.

7. Can You Interchangeably Use or Convert Bitmapped Images to Vector Images (and vice-versa)?

Yes. You can use both images in using Direct to Garment printesr.

As for converting from one to another, through the use of software, you can convert one image type to another:

Converting Bitmapped to Vector Images:

There are software tools available that can attempt to automatically convert bitmapped images to vector format. However, the results may vary depending on the complexity of the image and the quality of the conversion algorithm. Simple images with clear edges and distinct colors tend to convert more successfully.

Converting Vector to Bitmapped Images:

Vector images can be exported or rasterized into bitmapped formats like JPEG, PNG, or TIFF at a specified resolution. When exporting, consider the intended use and ensure the resolution is sufficient for the desired output size to avoid loss of quality. Some vector graphics software allows for applying bitmap effects to vector objects, simulating a bitmapped appearance. This can be useful for creating artistic effects or adding texture to vector artwork.

8. Can You Just Scan an Image and Print it on a Shirt Using a DTG Printer?

Yes, you can scan an image and print it on a shirt using a DTG (Direct-to-Garment) printer. Ensure that the image possesses adequate size and contrast for optimal scanning results, and scan it at a resolution of 300 dpi or higher. Keep in mind that scanned images are bitmap-based and altering their size can result in quality loss. While slight resizing may be feasible with minimal quality degradation, significant resizing will likely lead to noticeable loss of quality.

9. How Many Colours Do DTG Printers Produce?

DTG (Direct-to-Garment) printers are capable of producing a wide range of colors, typically exceeding the limitations of traditional screen printing methods. They can reproduce full-color designs with virtually unlimited color options, including gradients, shades, and complex color combinations. While the exact number of colors a DTG printer can produce is not strictly defined, it can effectively replicate millions of colors by mixing primary ink colors (cyan, magenta, yellow, and black) in various proportions. This versatility allows for vibrant and detailed prints with rich color accuracy, making DTG printing suitable for reproducing intricate artwork, photographs, and designs with multicolor elements.

10. Are There Differences When Printing in a White Garment vs Black/Darker Garments in DTG Printing?

Yes, there are significant differences when printing on white garments compared to black or darker garments in DTG (Direct-to-Garment) printing:

Printing on white garments is relatively straightforward since the fabric color is already light. Colors appear vibrant and true to the original design. Whereas printing on black or darker garments requires a white underbase layer to be printed first. This white layer acts as a base for the colors in the design to ensure opacity and vibrancy. The white underbase layer is essential for preventing the dark fabric color from showing through the printed colors, maintaining the integrity of the design. Colors may appear slightly muted or less vibrant compared to printing on white garments due to the layering of inks. Additional care is needed during the printing process to ensure proper curing of the white underbase and colors, as well as to prevent bleeding or smudging on dark fabrics.

11. Do I need to Treat the Garment After DTG Printing?

Yes, treating the garment after DTG (Direct-to-Garment) printing is typically necessary to ensure the longevity and durability of the print. The treatment process involves curing the ink using heat to bond it with the fabric fibers and improve wash fastness. The most common way is to use a heat press. This process helps set the ink into the fabric and enhances its durability and washability. The temperature and duration of heat application depend on the specific ink and fabric used.

12. Will the Ink from a DTG Printer Withstand Washing?

Yes, the ink used in DTG (Direct-to-Garment) printing is specifically formulated to withstand washing when properly cured and treated. After printing, the garment undergoes a curing process, typically with heat, to bond the ink with the fabric fibers. This curing process ensures that the ink becomes embedded into the fabric, resulting in durable prints that can withstand repeated wash cycles. Just make sure not to use bleach on any garments that went through a DTG printing.

13. What Type of Fabric Can I Print on Using a DTG Printer?

You can print on almost any fabric when using a DTG printer. It’s essential to consider the characteristics of the fabric, such as absorbency, texture, and composition, when choosing the appropriate DTG printing settings and techniques. Additionally, conducting tests and trials on different fabric types can help determine the optimal printing parameters for achieving high-quality and long-lasting prints.

14. Best DTG printer in 2024

Here are some of the best Direct to Garment printers available:

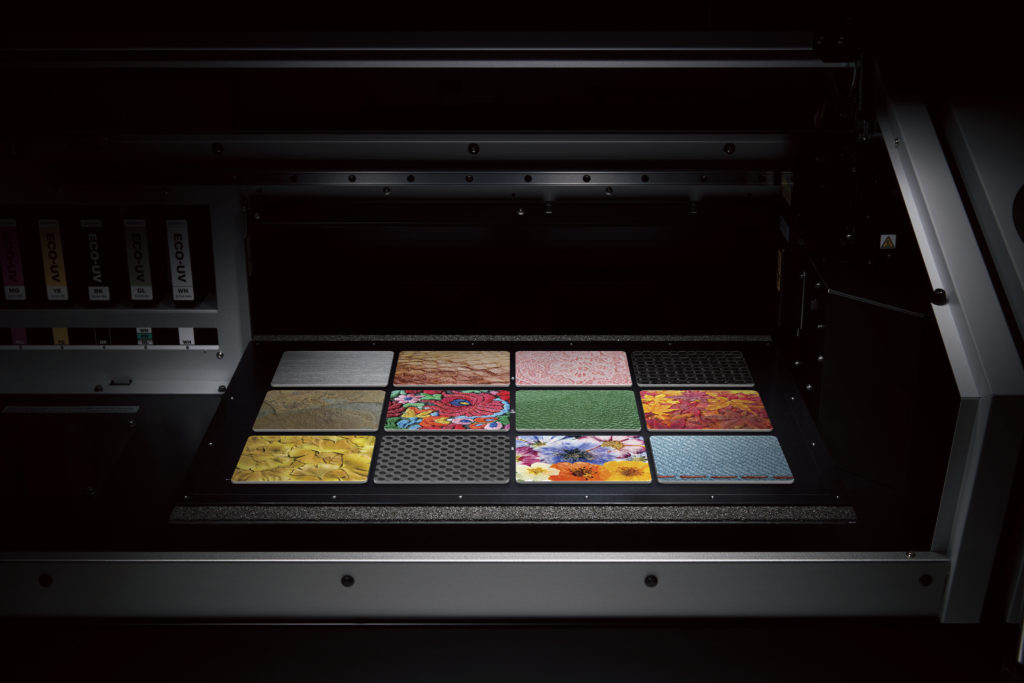

- Texart XT-640S DTG

Turns up the volume on t-shirts, apparel, and fabric accessory printing without the high-volume industrial price tag. - VersaStudio BN-20D Direct-to-Film Printer

The newest addition to the BN-20 Series of desktop printers. The BN-20D Direct-to-Film System complements Roland DGA’s existing family of compact, powerful VersaSTUDIO machines designed to help smaller home- or office-based print providers build their businesses.