Tag: lamination

How Lamination Works

In the world of commercial and professional printing, appearance, protection, and durability are just as important as design and colour accuracy. One way to achieve these qualities is through lamination, a widely used print finishing method that enhances the look and life of printed materials. Lamination helps businesses and organizations deliver polished, long-lasting products that can withstand frequent handling, environmental exposure, and general wear. This article explores how lamination fits into the broader category of print finishing techniques and its common applications across industries.

First, What is Print Finishing?

Print finishing refers to the final steps in the printing process that improve the physical appearance, texture, and functionality of printed pieces. These techniques help turn a standard print job into a refined, professional product. Some common print finishing options include binding, varnishing, embossing and debossing, die-cutting, spot UV, and foil stamping. Among these, lamination remains one of the most effective solutions for enhancing both protection and presentation.

While other finishing techniques may serve decorative or structural purposes, lamination provides a balanced combination of visual appeal and durability. This makes it a practical and essential step for printed materials that face frequent use, such as menus, business cards, book covers, ID cards, and instructional signage.

What Is Lamination in Printing

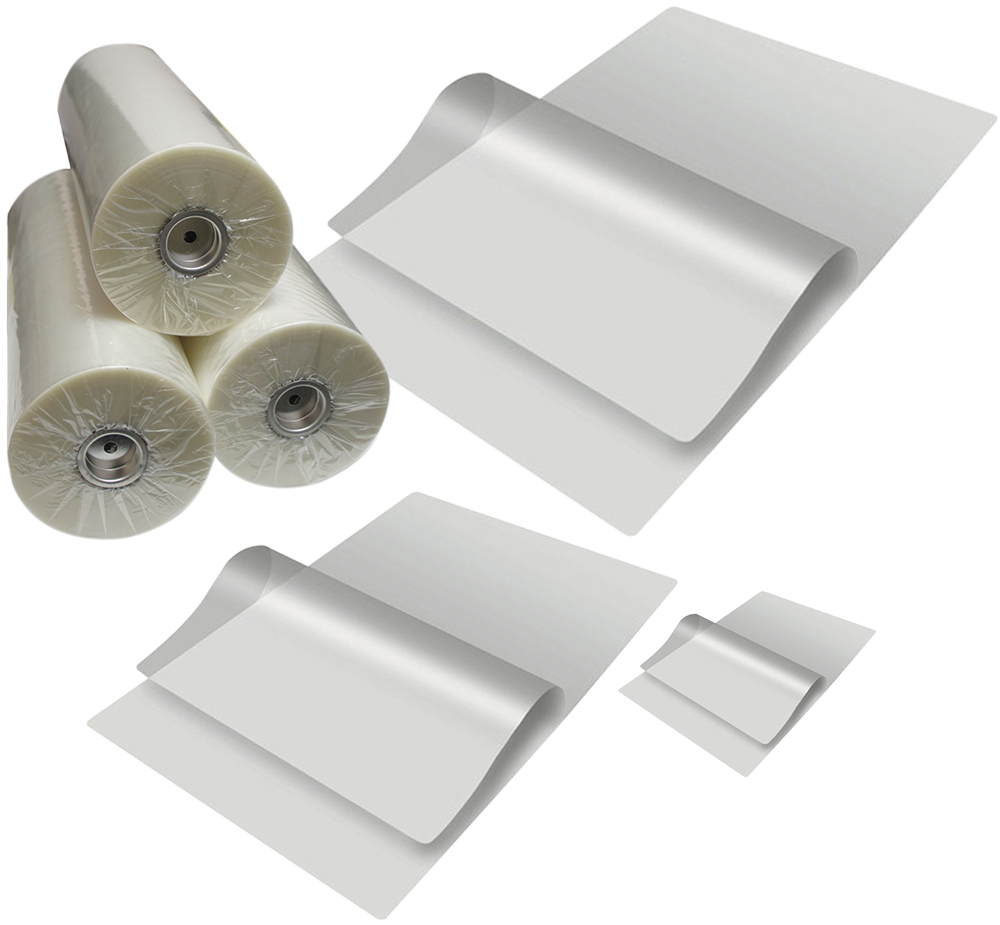

Lamination in printing involves applying a thin layer of plastic film over the surface of a printed sheet. This film acts as a protective barrier against moisture, smudges, dirt, scratches, and other environmental or physical damage. Lamination can also add a desired finish—glossy for vibrant colour enhancement, matte for a muted and elegant effect, or soft-touch for a premium, velvet-like texture.

Lamination not only preserves the integrity of the print but also enhances its tactile quality and colour contrast. The final product appears more vibrant, smooth, and professionally finished. This dual function of protection and visual improvement makes lamination a popular choice for both everyday and specialty printed items.

How It Works

The lamination process involves bonding plastic film to a printed sheet using either heat, pressure, or a combination of both. There are two main types of lamination:

Thermal lamination uses heat-activated adhesive on the film. As the material passes through heated rollers, the adhesive melts slightly and securely bonds to the surface of the print. This method is ideal for larger production runs and produces a consistent, high-quality finish.

Pressure-sensitive lamination, also known as cold lamination, uses adhesive film that sticks to the print when pressure is applied. This process is suitable for materials sensitive to heat or for projects requiring fast turnaround without additional curing time.

Lamination films vary in thickness and finish. Thicker films provide greater rigidity and protection, while thinner films are more flexible and economical. For added convenience, small-scale projects may use a laminating pouch, which consists of a pre-sealed film sheet designed for quick, individual lamination.

Common Applications of Lamination

Lamination enhances the performance and lifespan of printed materials across different sectors. Some of the most common uses include:

- Menus and restaurant materials: Lamination protects menus from spills, stains, and frequent handling. It also allows for easy cleaning without damaging the print.

- Business cards: A laminated finish gives business cards a more premium feel while protecting them from creases and smudges.

- Book covers and catalogues: Lamination extends the durability of frequently handled publications, helping them maintain their appearance over time.

- Posters and signs: Laminated signs are more resistant to fading and damage, especially when displayed outdoors or in high-traffic areas.

- ID cards and badges: Lamination adds rigidity and resistance to wear for cards that are used daily or require scanning.

- Instructional and safety materials: Laminated guides and signage last longer in environments like factories, classrooms, or construction sites.

- Packaging and labels: Lamination provides an attractive and protective surface for branded packaging, improving shelf appeal and resistance to misture or abrasion.

Best Laminators in 2025

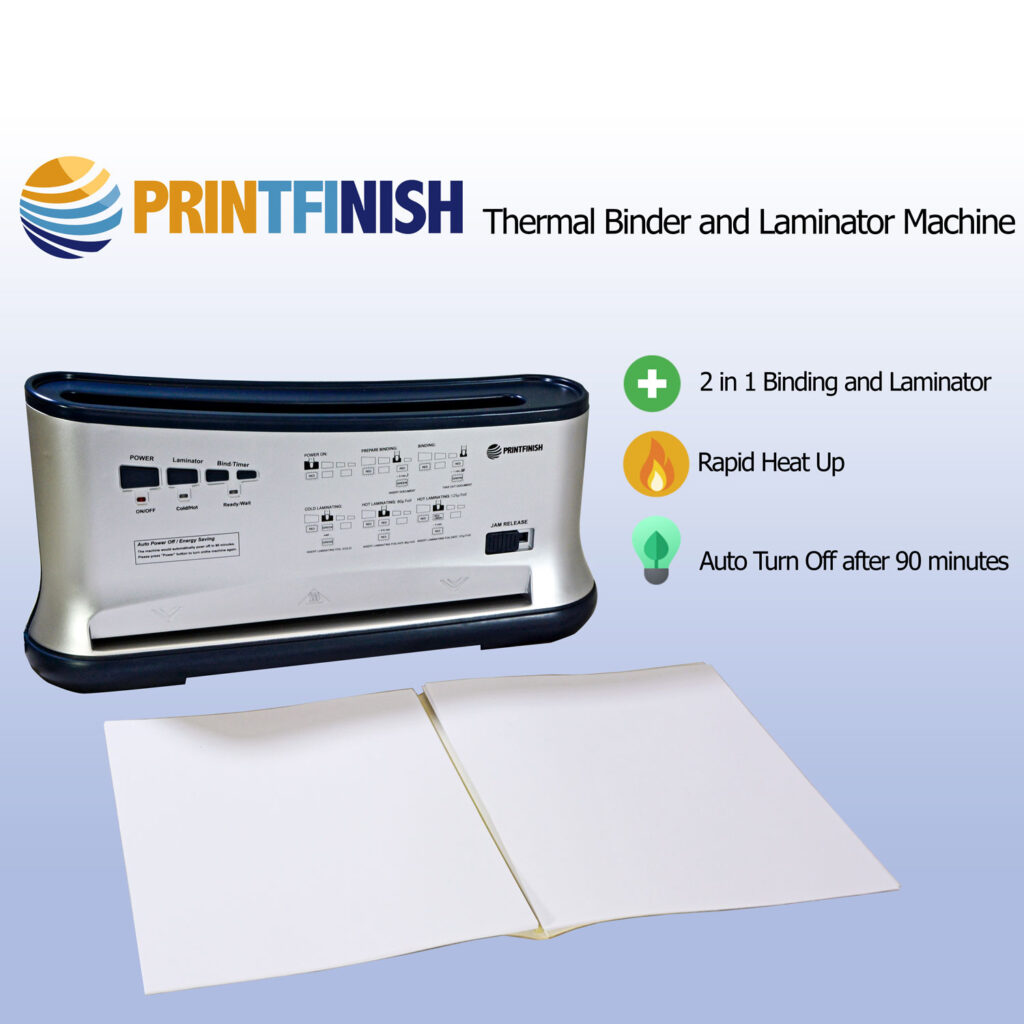

To apply lamination effectively, specific equipment is used depending on the scale and type of the project. A laminating machine uses heated or pressured rollers to apply film directly onto printed materials during the process.

Best Large Format Roll Laminators

For high-volume commercial printing, large-format roll laminators handle continuous sheets with speed and efficiency. These machines are ideal for posters, banners, and packaging applications that require consistent output and high durability.

- Sysform All-in-One Digital Laminator & Foiler FL-360

- SUPU FM-480 Roll Laminator 19″

- Thermal Binding with Laminator 12″ – LTB-200

- Sigmont 55H/65H Roll Laminator

- Royal Sovereign RSL 2702S

Best Pouch Laminators

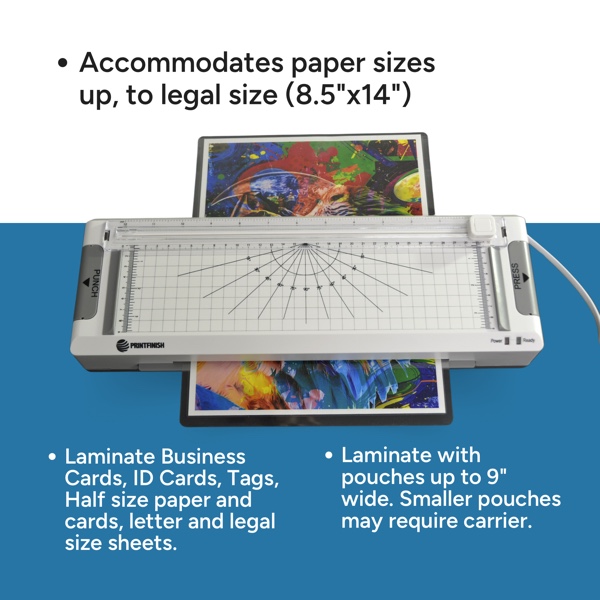

Smaller-scale operations often use pouch laminators, which are designed for individual sheets or small batches. These machines work with laminating pouches and are commonly used in offices, schools, and small print shops.

- Akiles ProLam Plus 330 13″ Pouch Laminator

- Akiles ProLam Photo 13″ Pouch Laminator

- Akiles ProLam Ultra Professional Photo Laminator

- Printfinish 4-in-1 Office Laminator LMTC402

Other commercial jobs may require laminating rolls, which feed long stretches of film into roll laminators for uninterrupted processing of large print runs. This method is especially useful for signage, maps, and packaging inserts.

Some advanced laminators feature adjustable temperature controls, multiple roller systems, and built-in cutters, supporting a wide range of film types and job requirements. Choosing the right laminating equipment depends on the size of the materials, the desired finish, and the volume of production.

Lamination plays a critical role in the print finishing process by adding a layer of durability and polish to printed materials. Lamination preserves the quality and professional appearance. As part of a broader suite of finishing techniques, it stands out for its versatility, effectiveness, and wide range of applications. Because it enhances both visual appeal and durability, lamination remains a smart and valuable choice for any business or individual.

If you’re a business owner in the office, binding, printing or publishing industry, and you’re seeking the best print-finishing machine to enhance your operations, look no further. Our selection of high-quality equipment is designed to meet your specific needs. Whether you require the durability of binding, the versatility of cutters, or the cost-effective benefits of large-format printers, we have the right binding solution for you. Contact us today to explore our range of binding machines and take your business to the next level.