Tag: print finish

How to Start a Print Finishing Business

The printing industry keeps growing as more businesses and individuals need professional printed materials. Printing alone does not complete the process. Customers want products that look sharp, feel premium, and last longer. This is where print finishing plays a vital role. A print finishing business adds value by protecting, enhancing, and refining printed materials. Starting such a business can be rewarding if you understand the process, the equipment, and the market.

What Is Print Finishing

Print finishing refers to the steps done after printing. These steps improve durability, function, and appearance. Finishing turns simple prints into polished products that stand out. It also ensures that printed items withstand frequent handling and maintain a professional appearance. Without finishing, most printed items would wear out quickly or fail to make an impression.

Examples include a laminated menu that resists spills or a bound catalogue that stays intact after heavy use. Print finishing adds that final touch which makes a product complete.

Why Print Finishing Matters

Every business wants its printed materials to reflect quality. Brochures, business cards, packaging, and manuals all represent a brand. If the finish is poor, the brand looks careless. Good finishing ensures the printed piece looks premium and reliable.

Finishing also protects against wear and tear. It keeps prints from fading, tearing, or smudging. For businesses, this means fewer reprints and higher customer trust. For individuals, it means treasured prints, such as invitations or photo books, last longer.

Types of Print Finishing

There are many print finishing methods. Each adds a unique benefit. Understanding these types will help shape your business services.

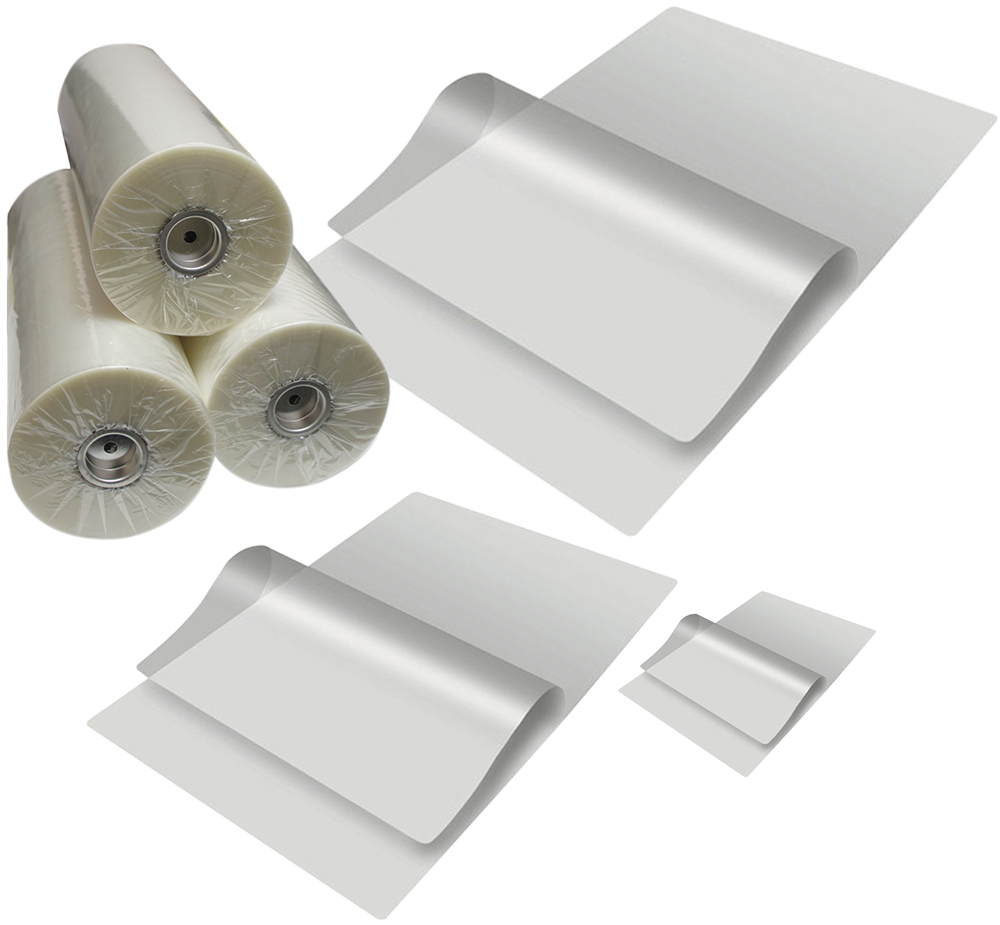

- Lamination: A plastic film applied to protect surfaces. It enhances colours and adds gloss, matte, or soft-touch effects.

- Binding: The process of securing pages together. Common methods include perfect binding, saddle stitching, and spiral binding.

- Embossing and Debossing: Techniques that create raised or recessed impressions for a tactile effect.

- Foiling: Adds metallic or holographic accents that make prints shine and look premium.

- Die-cutting: Cuts prints into shapes for creative designs, packaging, or labels.

- UV Coating: A glossy liquid finish cured with ultraviolet light. It gives prints a smooth and vibrant look.

- Varnishing: A clear layer applied to enhance shine or provide subtle protection.

Each technique serves different needs. Together, they open many opportunities for customer projects.

Notes to Remember Before Starting

Before starting your print finishing business, there are important details to keep in mind. These notes will guide your planning and decision-making.

First, identify your market. Small offices may only need simple lamination and binding. Publishers or corporate clients may demand premium finishes like foil stamping or embossing.

Second, study the cost of materials. Laminating film, binding wires, and coating supplies affect quality and profit. Low-cost materials can save money but may harm results.

Third, plan your pricing. Each finishing service has a cost in time, labour, and supplies. Prices must cover expenses while remaining competitive.

Fourth, invest in skilled staff. Finishing requires precision and practice. Mistakes can waste materials and delay delivery. Training is a key part of success.

Fifth, stay updated with technology. Machines improve each year and may save time and reduce waste. New techniques also attract clients looking for unique products.

Best Equipment to Use

The right equipment forms the backbone of your business. Each machine serves a different function. Choosing wisely will help you deliver reliable results.

Lamination machines apply protective film to printed sheets. They come in either a roll laminator or a pouch laminator. Laminating pouches are useful for small jobs, while laminating rolls handle bulk work.

Binding machines secure multiple pages into books, catalogues, or reports. Options include coil binders, comb binders, wire binders and thermal binders. The choice depends on project type and customer needs.

Paper cutting machines trim prints to precise sizes. Guillotine cutters handle large stacks, while smaller trimmers are best for low-volume jobs.

Shrink wrap sealers and heat tunnels package stacks of printed materials securely. They keep items safe during shipping and storage.

Embossing or foiling machines create premium finishes. They appeal to industries like luxury packaging, invitations, and branding materials.

Each machine requires investment and training. Start with the ones that match your target market and scale later.

Planning Your Print Finishing Business

Running a print finishing business requires clear planning. You need to think about more than machines and supplies.

Create a solid business plan. It should cover your services, target market, budget, and goals. Secure enough funding to cover equipment, materials, and staff. Find a location with enough space for machines and storage.

Also, focus on marketing. Build partnerships with local printers, publishers, and design agencies. They may outsource their finishing needs to your shop. A professional website and active social media can also attract clients.

Finally, focus on customer service. On-time delivery and consistent quality will earn trust and repeat business.

Challenges You May Face

Like any business, print finishing has challenges. Equipment maintenance can be costly. Machines need regular care to avoid breakdowns. Competition is another challenge. Many print shops offer finishing in-house, so you must stand out.

You may also face changing customer demands. Many clients now prefer eco-friendly materials. This may mean offering biodegradable laminates or recyclable packaging.

Managing deadlines can be stressful. Clients often need quick turnarounds. Strong planning and workflow management help meet these demands.

Opportunities for Growth

Despite challenges, opportunities are vast. Businesses always need marketing materials. Schools, offices, and publishers also need finishing services. You can offer specialty finishes like foiling or embossing for higher profits.

Packaging is another growth area. Brands want attractive, durable packaging to impress customers. Offering lamination, die-cutting, and foiling creates value for these businesses.

Digital printing continues to grow, and with it, the need for finishing. Print finishing businesses that adapt to trends will thrive.

Starting a print finishing business can be rewarding with the right plan and tools. Print finishing adds value, protection, and style to printed materials. It ensures products not only look professional but also last longer.

With many techniques to choose from, businesses can tailor services to different markets. By investing in reliable equipment and focusing on quality, a finishing business can grow steadily. Success comes from meeting customer needs, staying updated on trends, and delivering consistent results.

Print finishing transforms simple prints into lasting impressions. For entrepreneurs, it offers a solid path into a growing industry.

If you’re a business owner in the office, binding, printing or publishing industry, and you’re seeking the best binding machines to enhance your operations, look no further. Our selection of high-quality binding machines is designed to meet your specific needs. Whether you require the durability of case binding, the versatility of perfect binding, or the cost-effective benefits of saddle stitching, we have the right binding solution for you. Contact us today to explore our range of binding machines and take your business to the next level.