Tag: printing business tips

Top 10 Benefits of Investing in High-Quality Commercial Printers

Investing in high-quality commercial printers can be a game-changer for businesses across various industries, from retail and manufacturing to education and healthcare. Even for a printing business, having a dependable, top-tier printer can provide more than just basic functionality; it can enhance productivity, reduce costs, and support business growth. Here’s a look at the top 10 benefits of investing in a high-quality commercial printer.

1. Superior Print Quality

High-quality commercial printers are designed to produce sharp, vibrant prints with precise colour accuracy and clear detail. This level of quality is essential for professional documents, presentations, marketing materials, and branded communications. With advanced printing technology, commercial printers ensure that every print job meets high standards, enhancing the business’s image and professionalism.

2. Improved Efficiency and Speed

Commercial printers are built to handle high print volumes rapidly, significantly reducing the time spent waiting for print jobs. These printers are equipped with faster processing speeds and robust paper-handling capabilities, allowing businesses to maintain productivity even during peak times. Faster print speeds also mean that employees can spend more time focusing on core tasks, rather than managing print queues.

3. Cost Savings Over Time

While high-quality commercial printers may have a higher initial investment, they often result in long-term cost savings. With more durable components and lower failure rates, these printers minimize the need for frequent repairs or replacements. Additionally, many commercial printers offer features that help reduce ink and toner consumption, saving money on supplies.

4. Enhanced Security Features

Data security is crucial for any business, especially in sensitive information sectors. Many high-quality commercial printers come with built-in security features, such as user authentication, encryption, and secure print release. These features help protect confidential documents, prevent unauthorized access, and comply with industry regulations for data privacy.

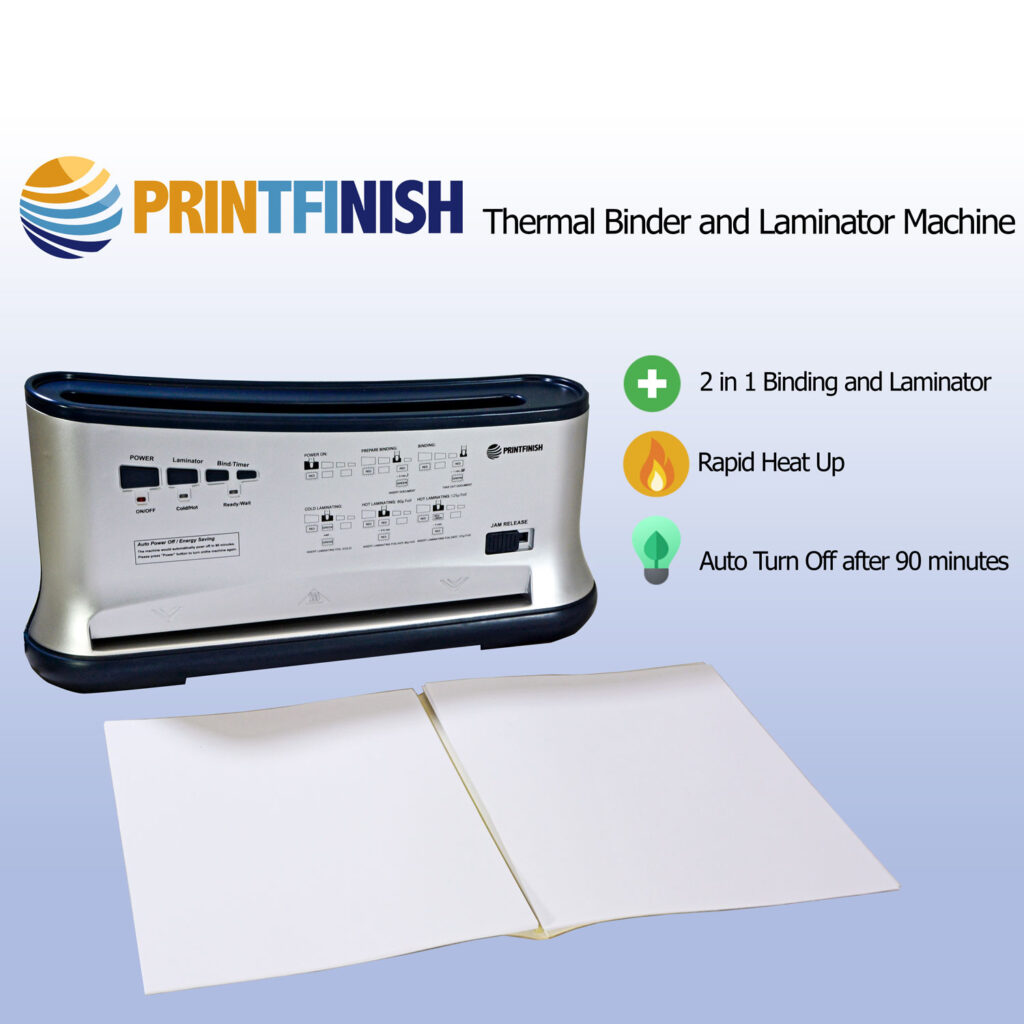

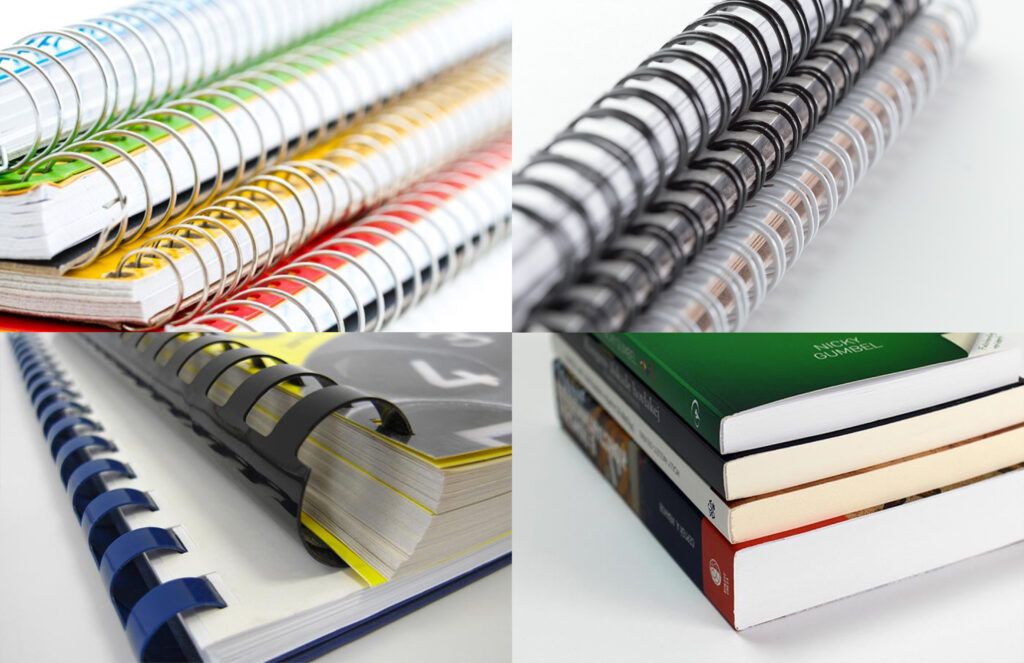

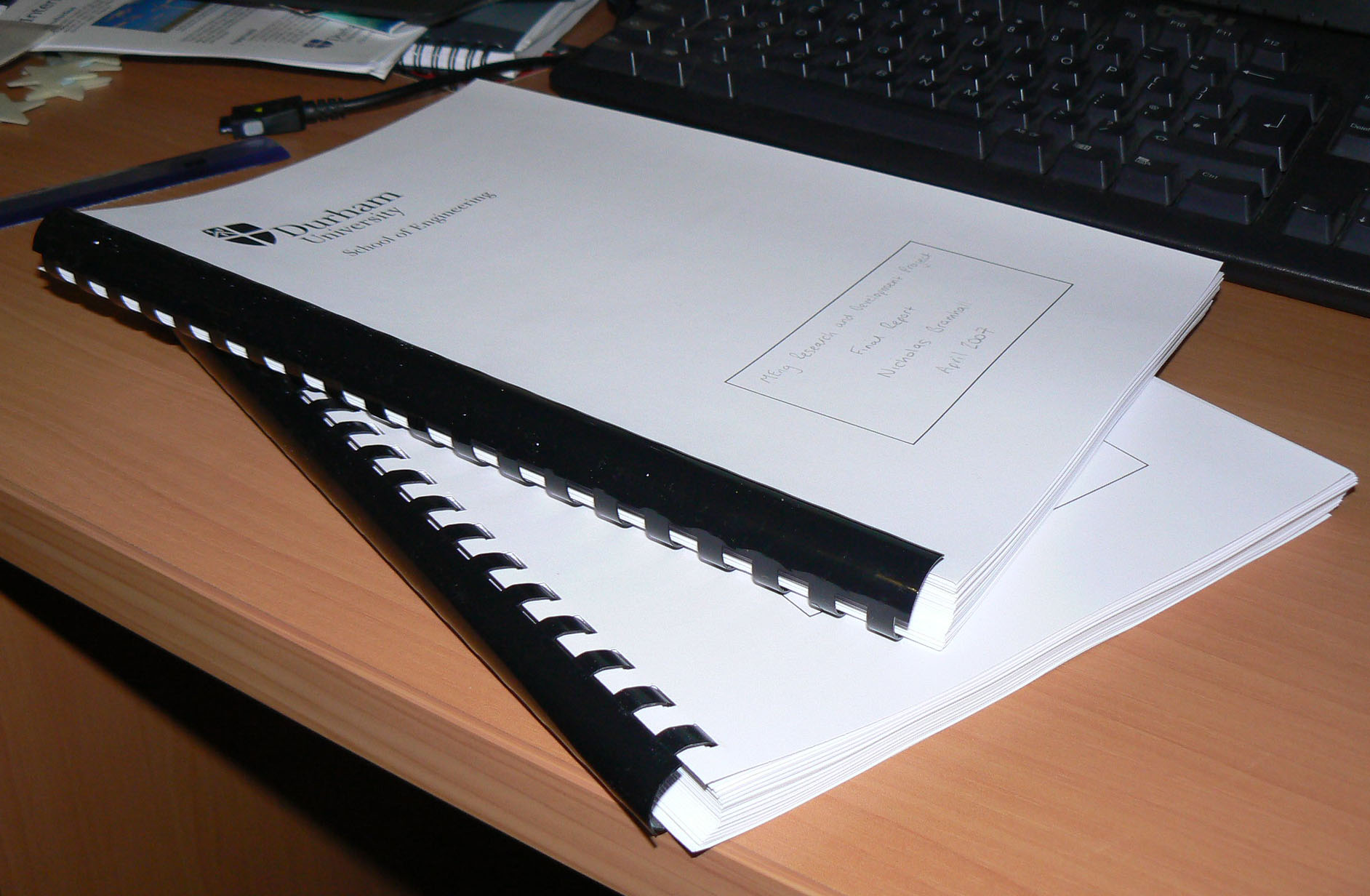

5. Greater Customization and Functionality

Commercial printers offer a wide range of customization options that allow businesses to adapt printing capabilities to their specific needs. Many models support multiple paper sizes, specialty finishes, and complex layouts. Advanced features like duplex printing, stapling, folding, and binding enable businesses to produce professional-quality documents in-house, reducing the need to outsource printing projects.

6. Reduced Downtime and Maintenance Costs

High-quality commercial printers are designed for durability and reliability, meaning they are less likely to break down or require constant repairs. These printers have components made to withstand frequent use, so they last longer and perform better under demanding conditions. Reduced downtime translates to more productivity and fewer interruptions, helping businesses meet deadlines and keep operations running smoothly.

7. Environmentally Friendly Options

Many commercial printers now have eco-friendly options, such as energy-saving modes, recyclable toner cartridges, and reduced power consumption. This is particularly beneficial for businesses looking to reduce their environmental impact. Additionally, features like duplex printing help conserve paper, and newer ink technologies can produce high-quality prints with less waste, supporting sustainability efforts.

8. Scalability to Meet Business Growth

As businesses grow, their printing needs often expand as well. High-quality commercial printers are built to accommodate increasing print demands, with some models able to support high monthly print volumes without performance degradation. This scalability ensures that businesses won’t need to replace their printer frequently, making it a valuable long-term investment.

9. Versatile Printing Capabilities

Commercial printers provide businesses with versatile printing options, which is especially useful for industries that require various print formats, such as marketing agencies, schools, or graphic design firms. High-quality printers can handle everything from basic black-and-white documents to full-colour presentations, posters, banners, and other specialty materials. This versatility makes it easy to meet a wide range of business needs without relying on multiple devices.

10. Enhanced Employee Productivity

The combination of speed, efficiency, and reliability that commercial printers provide significantly boosts overall employee productivity. Instead of dealing with printer issues, waiting for jobs to complete, or struggling with low-quality prints, employees can quickly get their print jobs done and return to their primary responsibilities. Additionally, modern commercial printers often come with user-friendly interfaces and wireless printing capabilities, making it easier for employees to print from any device or location within the workplace.

Investing in a high-quality commercial printer brings a host of advantages that go beyond mere functionality. From enhanced print quality and security to cost savings and increased productivity, a dependable commercial printer can be a powerful asset to any business. While the initial investment may be higher than consumer-grade models, the long-term benefits—such as reliability, scalability, and operational efficiency—make it worthwhile. As businesses continue to seek ways to operate more efficiently, improve their professional image, and support environmental goals, investing in a top-tier commercial printer is an effective and strategic choice.

Are you in the process of starting or expanding your large format printing business and in need of expert guidance on purchasing the right printing machine? Look no further! Our team of industry experts is here to provide you with valuable insights and expert opinions to help you make the best decision for your business. With a deep understanding of the large format printing industry, we can assist you in selecting the ideal printing machine that meets your specific requirements and budget. Contact us today for a personalized consultation and let us help you make the right investment for your business’s growth and prosperity.