Tag: printing tips

Printing 101: Beginner’s Guide to Printer Calibration

Regular printer maintenance is the unsung hero behind smooth and efficient printing operations. Whether you’re in the realm of home office printing or managing a large-scale commercial print shop, keeping your printer in optimal condition is essential. It ensures consistent print quality, extends the lifespan of your equipment, and minimizes costly breakdowns. However, amid the various aspects of printer maintenance, one step stands out as a linchpin for achieving pristine prints: printer calibration.

Printer calibration is needed across a spectrum of industries and sectors, ranging from professional photographers and graphic designers striving for colour accuracy and precision in their prints, to commercial printing companies ensuring consistent quality in their output. It’s invaluable for businesses engaged in marketing and branding, where colour fidelity is vital for maintaining a consistent brand identity. Moreover, it’s crucial in fields like architecture and engineering, where accurate reproductions of technical drawings and blueprints are essential. In essence, printer calibration is a fundamental practice for anyone seeking top-tier print quality, from creative professionals to businesses relying on visual communication.

This beginner’s guide unravels the complexities of this crucial process, shedding light on its significance, methods, and the difference it can make in the quality of your printed materials. Whether you’re a seasoned print professional or a novice looking to optimize your printer’s performance, you’ll discover valuable insights to keep your equipment running like a well-oiled machine.

First, What is Printer Maintenance?

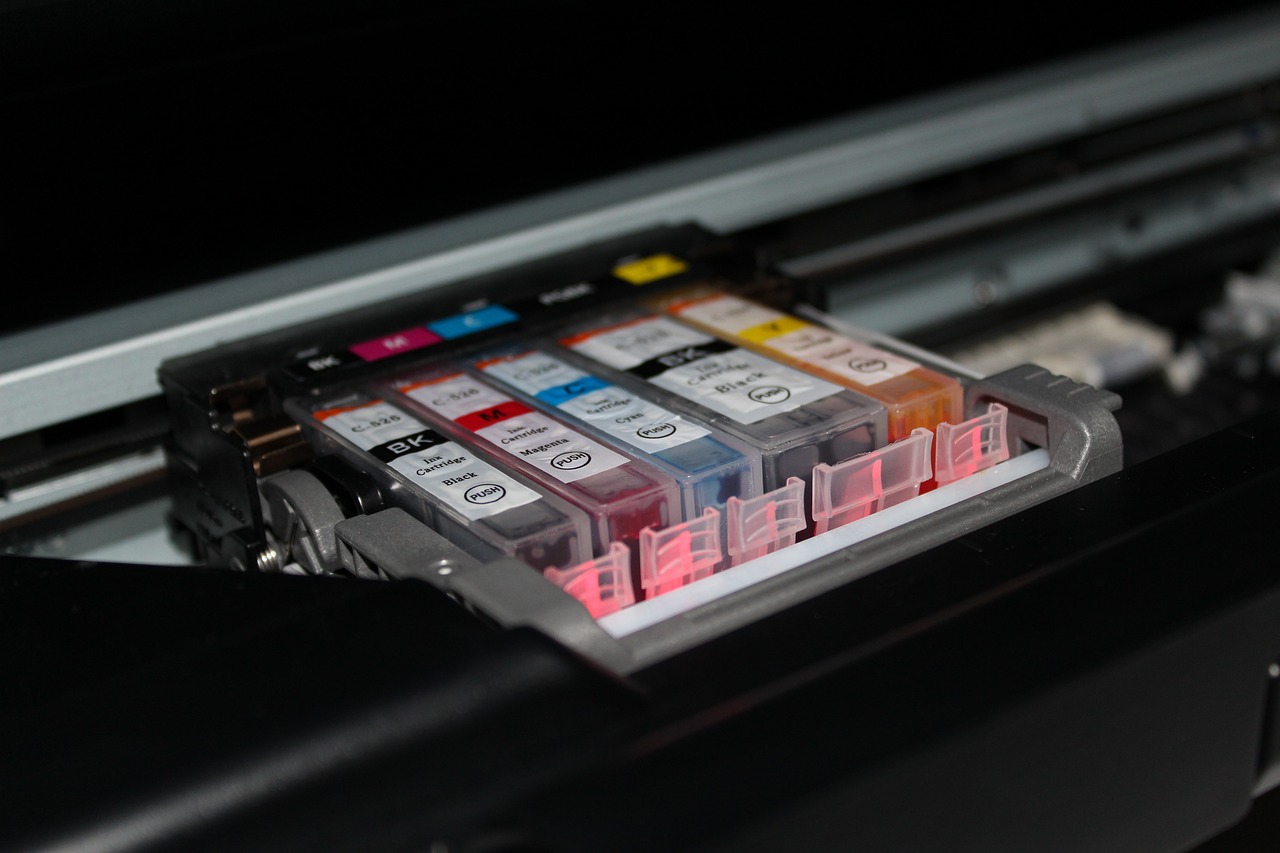

Printer maintenance encompasses a series of routine tasks and practices designed to keep a printer in optimal working condition. It involves a range of activities, from cleaning and inspecting various printer components to ensuring that the machine operates at peak efficiency. Maintenance not only helps prevent breakdowns and costly repairs but also plays a crucial role in maintaining consistent print quality. It includes tasks like cleaning the printheads, inspecting and replacing worn-out parts, checking for and removing paper jams, and calibrating the printer for accurate colour reproduction. By regularly performing these maintenance tasks, printer owners can prolong the lifespan of their equipment, reduce downtime, and ensure that prints remain sharp and true to colour.

What is Printer Calibration?

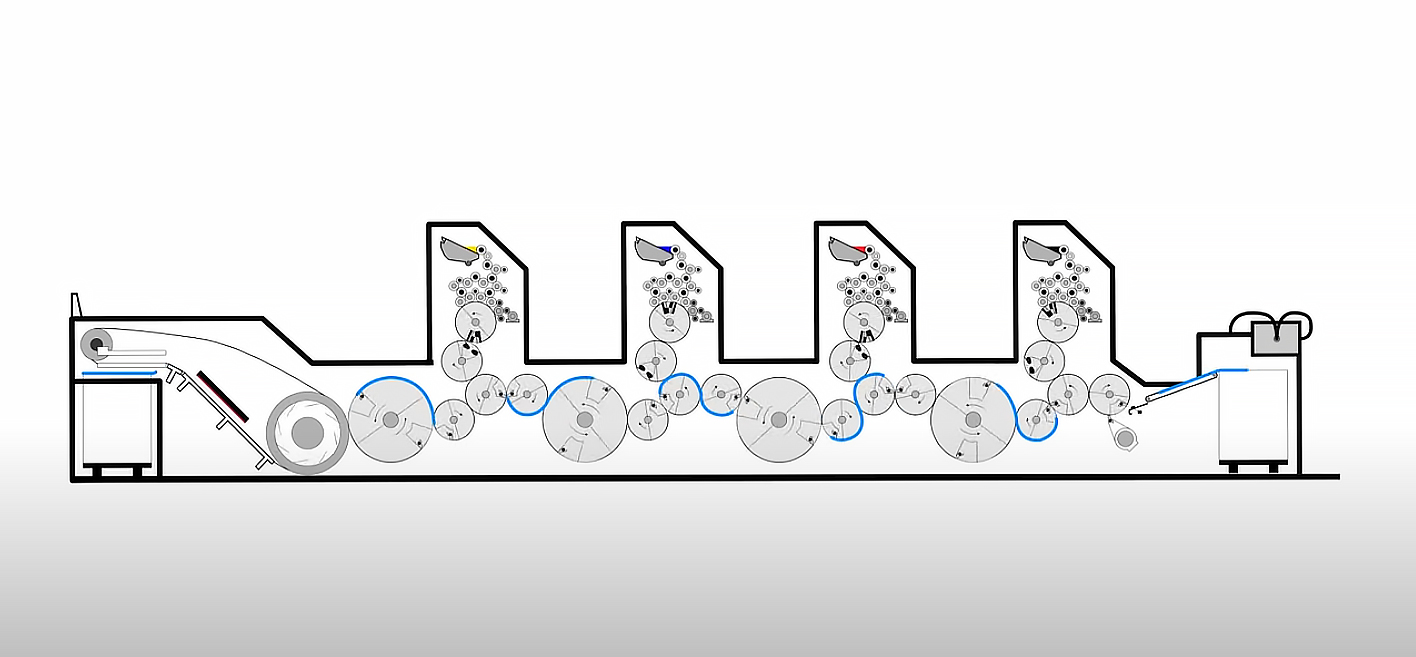

Printer calibration is a vital process in the printing industry that involves adjusting a printer’s settings and colour output to ensure accurate and consistent results. It aims to align the printer’s colours with established standards and correct any deviations that may occur over time due to factors like ink variations and wear and tear. Calibration helps achieve precise colour matching, which is critical for industries like graphic design, photography, and printing, where colour accuracy is paramount. By fine-tuning the printer’s settings through calibration, users can produce high-quality prints that faithfully reproduce colours as intended, resulting in professional and consistent output.

Why is Printer Calibration Important?

In the digital age, where images and designs span across screens and paper, ensuring that what you envision is precisely what you get on the printed page is vital. Printer calibration is the secret sauce that bridges the gap between your digital creations and their physical manifestations. It’s the process of fine-tuning your printer’s performance to produce colors, tones, and details that mirror your original designs. Without proper calibration, colors may appear distorted, images might lack detail, and your prints may fall short of your expectations. In this guide, we’ll demystify the calibration process, providing you with the knowledge and tools to unleash the full potential of your printer and achieve stunning, true-to-life prints.

How to Do Printer Calibration

Performing printer calibration is a crucial step to ensure accurate and consistent colour output from your printer. Here’s a step-by-step guide on how to do printer calibration:

- Gather Essential Tools and Materials:

Ensure you have access to your printer, computer, and the software used for calibration. You may also need calibration test patterns or colour management tools. - Prepare the Environment:

Make sure the area where your printer is located has consistent lighting conditions, as variations in light can affect colour perception. - Update Printer Drivers:

Ensure your printer drivers are up-to-date. Visit the manufacturer’s website to download the latest drivers if needed. - Calibration Software:

Use colour calibration software or tools designed for your specific printer model. - Clean Your Printer:

Ensure your printer is clean, free from dust, and in good working condition. This prevents any interference during calibration. - Load Manufacturer Calibrated Media:

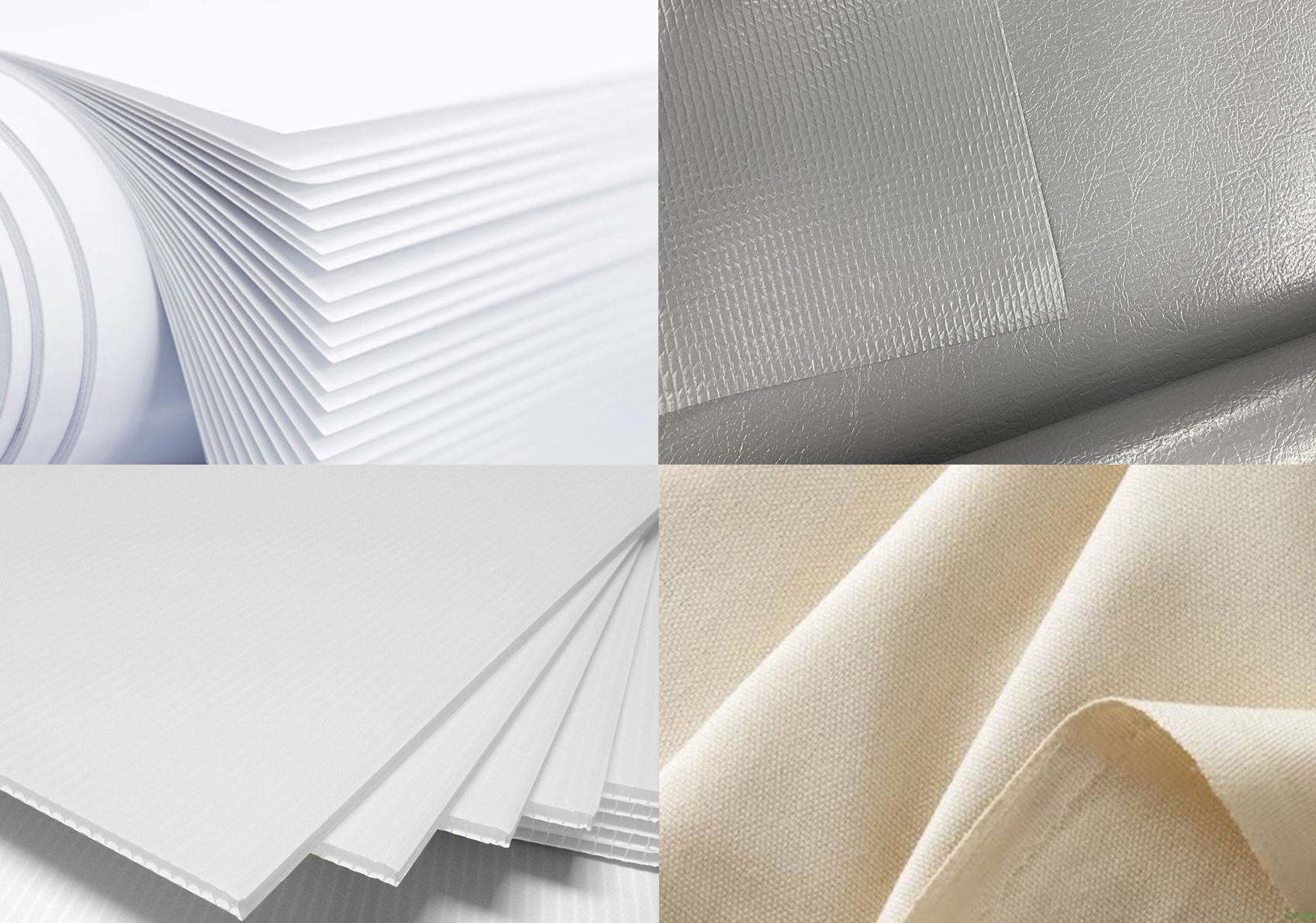

Use high-quality, colour-calibrated media that is designed for your printer type. - Print Calibration Test Patterns:

Follow the instructions provided by the calibration software to print test patterns. These patterns typically include colour patches and grayscale gradients. - Measure Colour Accuracy:

Use a colorimeter or spectrophotometer to measure the colour accuracy of the printed test patterns. These devices analyze the colours produced by the printer and compare them to reference values. - Adjust Printer Settings:

Make sure you are using calibrated profiles for your rip/ink/media configuration to ensure accurate colour production. For example, Roland DG wide format printers have calibrated profiles for many rip/ink/media at www.rolandprofilecenter.us. It’s free to create an account and download and install the appropriate profile. - Repeat the Process:

Depending on your calibration software, you may need to repeat the process multiple times until you achieve the desired colour accuracy. - Save Calibration Profile:

Save the calibration profile within your printer settings or colour management software. This profile will help maintain consistent colour output for future print jobs. - Regular Maintenance:

Perform regular maintenance checks and recalibrate your printer as needed to account for changes over time.

By following these steps, you can ensure that your printer produces accurate and consistent colours, which is essential for various industries like graphic design, photography, and professional printing. Calibration helps you achieve reliable and high-quality prints that match your intended colour output.

Tips and Reminders When Doing Printer Maintenance

Here are quick and simple tips for printer maintenance:

- Regular Cleaning: Keep your printer clean by dusting and wiping down surfaces.

- Use Quality Printer Supplies: Use genuine ink or toner cartridges and high-quality paper.

- Update Drivers: Keep printer drivers and firmware updated for optimal performance.

- Check Connections: Ensure all cables and connections are secure.

- Clear Paper Jams: Promptly remove any paper jams to prevent damage.

- Storage: Store paper and supplies in a cool, dry place to avoid issues.

- Scheduled Printer Maintenance: Follow manufacturer-recommended maintenance schedules.

- Test Prints: Periodically print test pages to check for issues.

- Professional Service: When needed, consult a professional technician for repairs.

These simple steps can extend your printer’s lifespan and maintain print quality.

In conclusion, printer calibration is a fundamental process that ensures your prints remain accurate, vibrant, and true to your vision. By following the steps outlined in this guide and regularly calibrating your printer, you can achieve consistent and professional results. Remember that calibration is not a one-time task; it’s an ongoing practice that pays off in the form of stunning prints and reduced frustration. So, take the time to calibrate your printer

If you’re a business owner looking to maintain the peak performance of your printers or considering upgrades, we’re here to assist you every step of the way. Our team specializes in printer parts replacement and upgrades, ensuring your equipment runs smoothly and efficiently. Whether it’s a replacement part or an entire upgrade, we provide top-quality solutions tailored to your needs. Don’t wait until your printers face critical issues; take proactive steps to keep your operations running smoothly. Contact us today, and let’s discuss how we can optimize your printing infrastructure for maximum productivity.