Tag: guide for printing business

9 Benefits of Using Wire Binding Method

In today’s world, how you present your documents matters. Among various binding methods, wire binding stands out for its practical benefits. Understanding its advantages is important across industries. In this article, we’ll explore why wire binding matters, its relevance across sectors, and its many advantages. Let’s uncover why wire binding is preferred for professionals aiming to improve document presentation and organization.

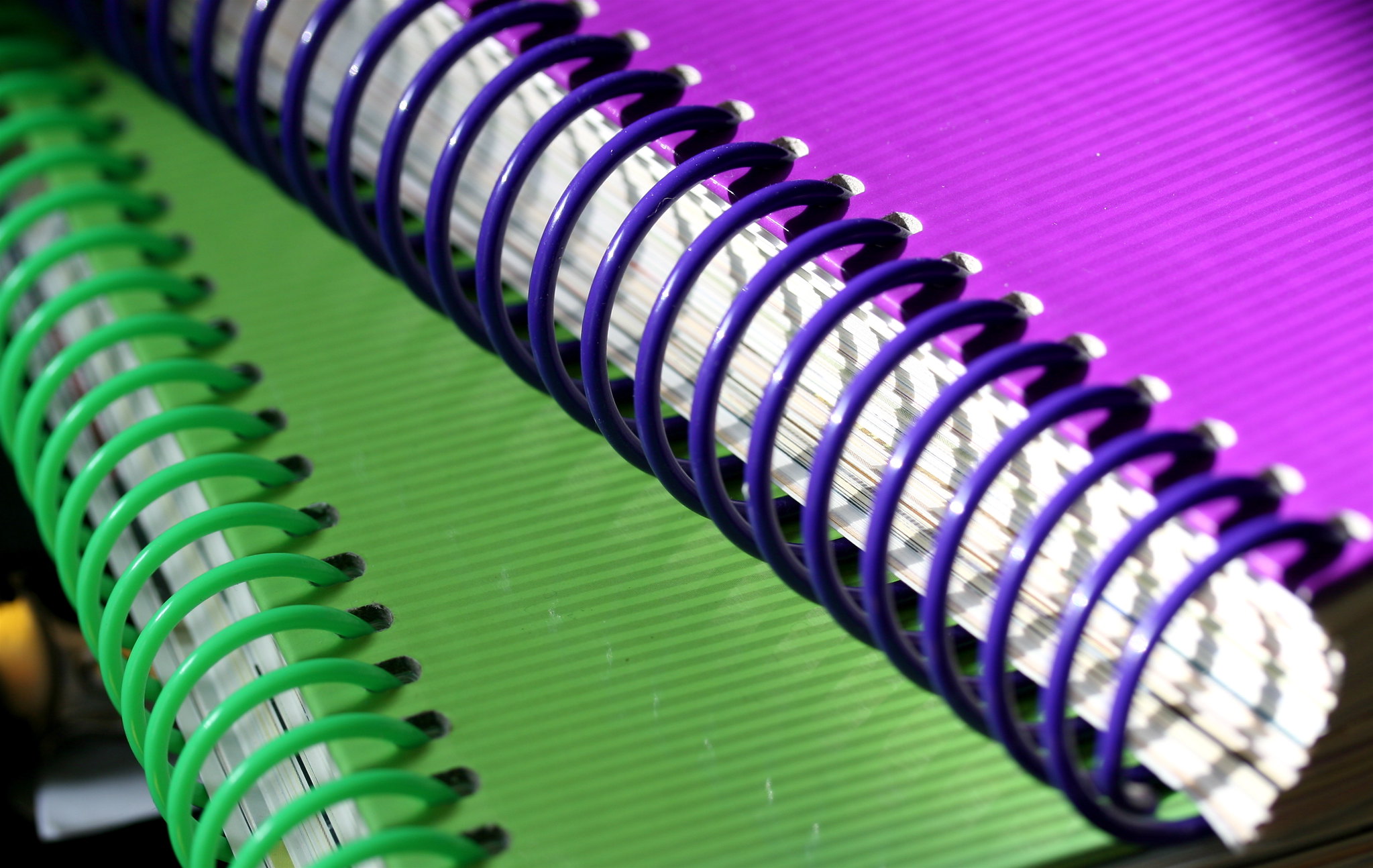

What is Wire Binding?

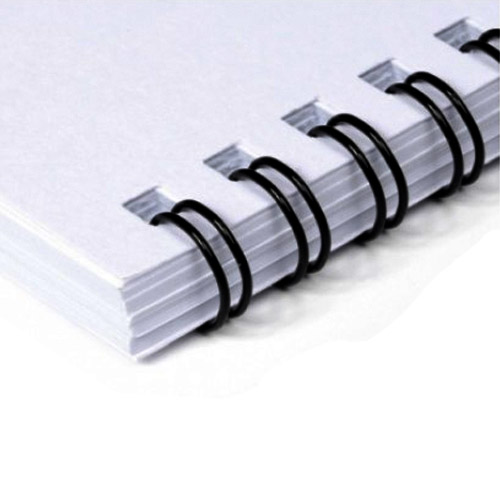

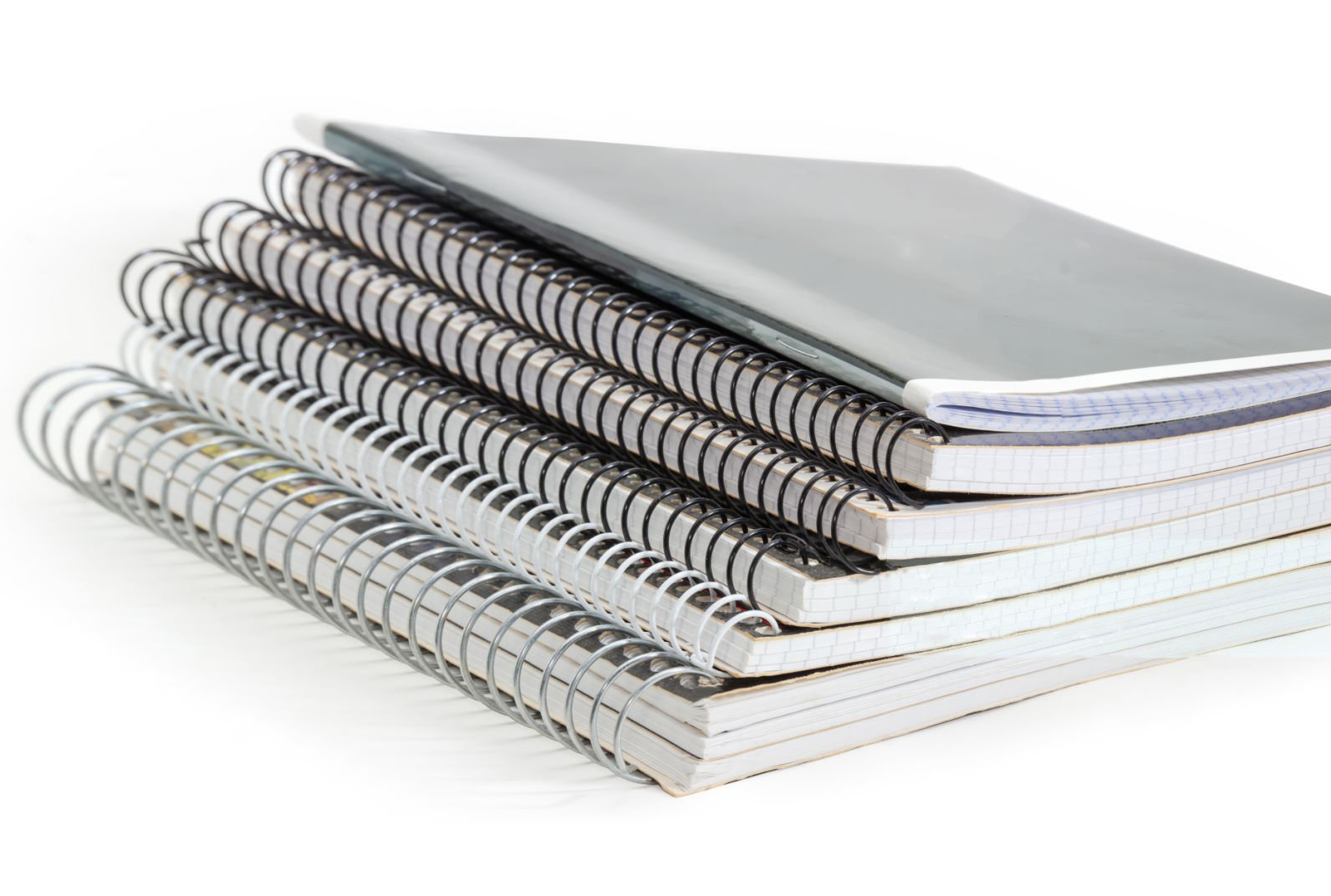

Wire binding, or Wire-O binding, is a method used to secure the pages of a document together by threading a metal wire or coil through small holes along the edge of the pages. This creates a sturdy spine that holds the pages in place, allowing the document to be opened flat or folded back on itself for easy reading and referencing. Wire binding is commonly used for reports, presentations, manuals, notebooks, and other documents where durability, professional appearance, and ease of use are important factors.

Benefits of Using Wire Binding Method

1. Durability and Longevity

Wire binding, often using metal wire, provides exceptional durability. The sturdy wire spine ensures that the pages remain securely bound even with frequent handling and transportation. Unlike traditional binding methods like staples or glue, wire binding prevents pages from falling out or getting detached over time. This durability ensures that documents retain their integrity, making wire binding an ideal choice for materials meant for long-term use.

2. Lay-Flat Design

One of the significant advantages of wire binding is its ability to allow documents to lay completely flat when opened. This feature is particularly beneficial for presentations, manuals, or instructional materials where ease of reading and writing is crucial. Whether it’s a training manual on a workbench or a recipe book in the kitchen, wire-bound documents offer unmatched convenience, making them practical for various applications.

3. Professional Appearance

Wire binding exudes a professional appearance that instantly elevates the presentation of any document. The clean and sleek finish provided by the wire spine adds a touch of sophistication, making wire-bound documents suitable for business reports, proposals, and client presentations. The customizable covers and spines further enhance the professional look, allowing users to tailor the appearance to suit their branding or personal preferences.

4. Easy Editing and Revising

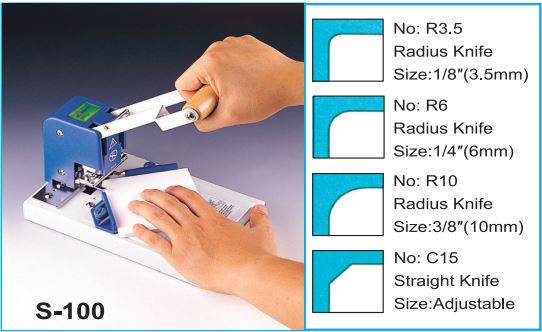

Unlike other binding methods that require cutting or heating to remove or add pages, wire binding offers effortless editing and revising capabilities. Users can easily open the wire spine, remove or insert pages as needed, and then close it back without damaging the document. This flexibility is invaluable for documents that require frequent updates, such as training manuals or product catalogues, saving time and resources in the long run.

5. Versatility

Wire binding accommodates a wide range of document sizes, from small booklets to large presentations. Whether binding a few pages or a thick volume, wire binding can easily handle various thicknesses, providing flexibility and versatility for different projects. Additionally, wire binding supports both landscape and portrait orientations, allowing users to customize the layout according to their preferences or requirements.

6. Cost-Effectiveness

In comparison to alternative binding methods, wire binding offers excellent value for money. The initial investment in a wire binding machine is relatively affordable, and the ongoing cost of wire spines is budget-friendly. Moreover, the durability of wire-bound documents reduces the need for reprints or replacements, resulting in long-term cost savings for businesses and organizations.

7. Eco-Friendly Option

Wire binding aligns with sustainability goals as it allows for the easy recycling of documents. Unlike some binding methods that involve adhesives or laminates, wire binding uses metal wires that are recyclable. Additionally, the longevity of wire-bound documents reduces paper waste, making it an environmentally responsible choice for businesses and individuals striving to minimize their ecological footprint.

8. Enhanced Branding Opportunities

Wire binding offers ample opportunities for branding and customization. From personalized covers featuring company logos to custom-printed spines with titles or dates, wire-bound documents can be tailored to reinforce brand identity and messaging. This branding potential extends to various marketing materials, including brochures, presentations, and promotional booklets, allowing businesses to make a lasting impression on clients and stakeholders.

9. Secure Document Preservation

Wire binding provides a secure and tamper-resistant method of document preservation. The wire spine tightly binds the pages together, minimizing the risk of unauthorized access or alterations. This feature is particularly valuable for sensitive documents, such as legal contracts, financial reports, or confidential proposals, where data security and integrity are paramount.

Further reading: 10 FAQs About Wire Binding

Best Wire Binding Machines

Here are some of the best wire-binding machines:

- WireBind W20A Wire Binding Machine

- Supu CW430E Electric Wire-o Punching Machine with Manual Closer

- WireMac-E31 Akiles Electric Punch Manual Wire

- Akiles WBM532 Modular Wire Binding Machine

- Akiles FlexiCloser 2 Wire Binding Machine

Other Types of Binding Method

Other types of binding methods include:

- Comb binding, or cerlox binding, uses plastic combs with teeth to secure the pages.

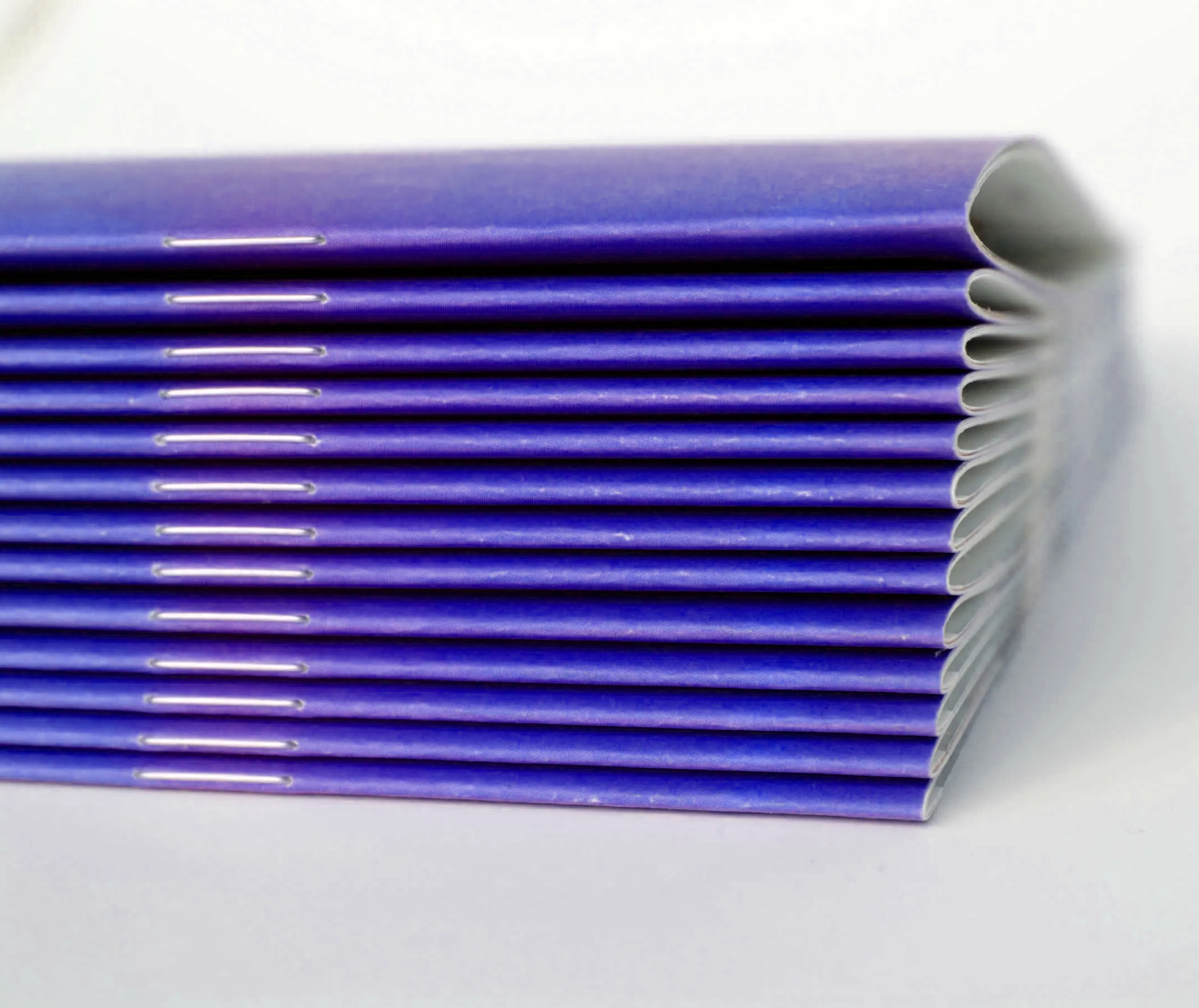

- Coil binding, also known as spiral binding, is similar to wire binding but uses a flexible plastic coil instead of metal wire.

- Thermal binding, where a heat-activated adhesive is used to bind the pages together.

- Saddle stitching, which involves stapling sheets along the fold line.

- Perfect binding, or soft cover binding, is characterized by the use of adhesive to bind the pages together.

- Case binding, or hardcover binding, is a bookbinding method used to create books with rigid and durable covers, typically made of thick cardboard or binder board.

Each binding method has its own advantages and suitability for different types of documents and purposes, ranging from cost-effectiveness and ease of use to aesthetic appeal and durability.

In conclusion, wire binding offers many benefits that make it a preferred choice for document binding and presentation. From its durability and lay-flat design to its professional appearance and editing flexibility, wire binding ticks all the boxes for functionality, aesthetics, and cost-effectiveness. Whether it’s for business, academic, or personal use, wire binding delivers unrivalled performance and versatility, making it a staple in the world of document organization and presentation.

If you’re a business owner in the office, binding, printing or publishing industry, and you’re seeking the best wire binding machines to enhance your operations, look no further. Our selection of high-quality binding machines is designed to meet your specific needs. Whether you require the durability of case binding, the versatility of perfect binding, or the cost-effective benefits of saddle stitching, we have the right binding solution for you. Contact us today to explore our range of binding machines and take your business to the next level.