Tag: perfect binding machines

7 Things to Remember When Buying a Perfect Binding Machine

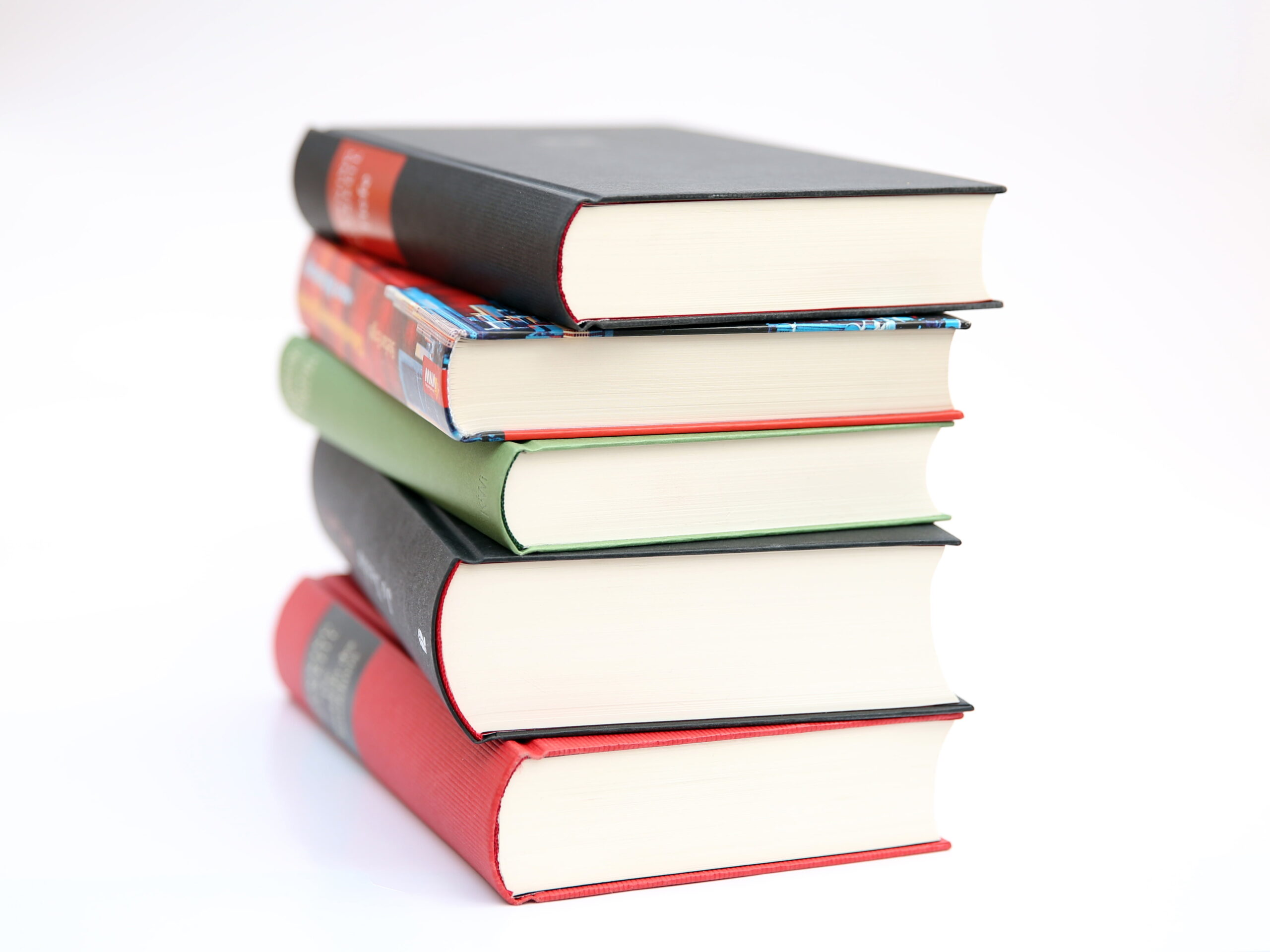

Perfect binding is a popular bookbinding method used to create a professional, durable, and polished finish for softcover books, magazines, catalogues, and manuals. It is commonly seen in publications like paperback books and corporate reports. The pages are bound together with adhesive along the spine, which is then attached to a cover, producing a sleek, flat-spined product.

For businesses, print shops, or individuals looking to invest in a perfect binding machine, there are several factors to consider before making a purchase. Perfect binding machines vary in size, capabilities, and costs, so choosing the right one for your needs is essential. This article will outline key factors to remember when buying a perfect binding machine, ensuring you make a well-informed decision.

What Is Perfect Binding

Perfect binding is a popular bookbinding method where the pages of a book are glued together at the spine with a strong adhesive and then attached to a soft cover. Unlike saddle stitching or spiral binding, which uses staples or coils, perfect binding results in a flat, professional-looking spine, making it ideal for paperback books, magazines, catalogues, and other multi-page publications. This method is commonly used for producing higher-quality, longer-lasting documents with a sleek appearance, offering a durable yet cost-effective solution for medium to large-sized print projects.

Tips When Buying a Perfect Binding Machine

1. Understand Your Production Volume

The first and most important factor to consider when buying a perfect binding machine is the volume of production. Understanding your printing needs will help determine the type of machine you require. Perfect binding machines come in various models that cater to different production levels, from low-volume machines for small print shops to high-capacity machines used by large-scale commercial printers.

2. Machine Size and Space Requirements

Perfect binding machines vary significantly in size, so it’s important to consider the available space in your print shop or office. Larger machines are often required for high-volume production, but they can take up considerable floor space. Before purchasing, ensure you have enough room to accommodate the machine and allow for ease of operation, maintenance, and material handling.

Additionally, consider the machine’s mobility. Some perfect binding machines are designed with casters for easy movement, which can be useful if you need to reconfigure your workspace or store the machine when not in use. On the other hand, larger machines are often stationary and require a permanent location.

3. Binding Capacity

Another crucial factor to consider is the binding capacity of the machine. Binding capacity refers to the maximum number of pages the machine can bind in a single book or the thickness of the book it can handle. The number of pages bound can vary significantly between different machines, so it’s important to choose a machine that matches your typical project requirements.

4. Binding Speed

The speed at which a perfect binding machine operates is another important consideration, especially for businesses with high production demands. Binding speed refers to the number of books or documents the machine can bind per hour. If your business requires fast turnaround times for large print runs, you’ll need a machine that offers high-speed binding.

Assess your production deadlines and the speed at which you need to complete projects to determine the appropriate machine for your business.

5. Adhesive Types and Quality

The quality of the adhesive used in perfect binding is critical to the durability and appearance of the finished product. Most perfect binding machines use hot melt glue, which provides a strong bond for softcover books. When selecting a machine, consider whether it supports different types of adhesives and how easy it is to switch between them.

- Hot Melt Adhesive: The most common adhesive used in perfect binding. It heats up quickly and cools rapidly, allowing for fast production. Hot melt glue is ideal for most standard binding projects.

- PUR Adhesive: Polyurethane Reactive (PUR) adhesive offers a stronger, more flexible bond than traditional hot melt glue. It is ideal for projects that require extra durabilities, such as high-use manuals or catalogues. However, PUR adhesive machines tend to be more expensive and may require additional maintenance.

Choose a machine that works with the adhesive type best suited for your projects and clients’ needs. If you require more durability and flexibility, a machine that supports PUR adhesive may be worth the investment.

6. Ease of Use and Automation Features

Ease of use is an important consideration, especially if your business has multiple operators using the machine. Look for machines with intuitive controls, clear displays, and straightforward setup processes. Many modern perfect binding machines come equipped with automation features that simplify the binding process, reduce human error, and improve efficiency.

When evaluating ease of use, consider the level of experience your operators have and whether the machine offers training features or requires specialized knowledge.

7. Maintenance and Durability

Investing in a high-quality perfect binding machine that is durable and easy to maintain will save your business time and money in the long run. Machines that require frequent repairs or part replacements can slow down production and increase operational costs. Look for machines with a solid reputation for reliability and minimal maintenance needs.

It’s also important to consider the availability of parts and customer support. Choose a machine from a reputable manufacturer that offers a strong warranty, readily available replacement parts, and responsive customer service. Regular maintenance, such as cleaning and lubrication, will help keep your machine running smoothly and extend its lifespan.

Best Perfect Binding Machines in 2024

Here are some of the best perfect binding machines:

- Boway Perfect Binder BW-JB2

- Boway Perfect Binder BW-920V

- Sysform 50A Professional Perfect Binding Machine

- Sysform 50B Professional Perfect Binding Machine

When buying a perfect binding machine, it’s essential to carefully consider your production volume, binding capacity, adhesive quality, machine size, speed, and ease of use. By understanding your specific needs and the capabilities of different machines, you can make an informed decision that aligns with your business goals. With the right perfect binding machine, you’ll be able to produce professional-quality books and documents that meet the demands of your clients and projects.

Are you a business owner seeking to elevate the presentation of your publications, from catalogues to manuals and beyond? Transform the way you showcase your content with the efficiency and professionalism of perfect binding machines. Take the next step in enhancing the quality and durability of your printed materials. Explore our range of perfect binding solutions today and invest in the tools that will set your business apart. Contact us today to discuss how our perfect binding solutions can meet your unique needs.