Tag: printing business tips

FAQs About Perfect Binding

Perfect binding is a widely chosen method for creating sleek and professional-looking documents. As businesses and individuals strive for efficient and aesthetically pleasing ways to present their materials, perfect binding emerges as a straightforward solution. Whether assembling reports, manuals, brochures, or books, understanding perfect binding’s fundamentals can aid in making informed binding decisions. In this article, we explore frequently asked questions about perfect binding, covering its process, advantages, applications, and considerations, providing comprehensive insights into this versatile binding method.

What is Perfect Binding?

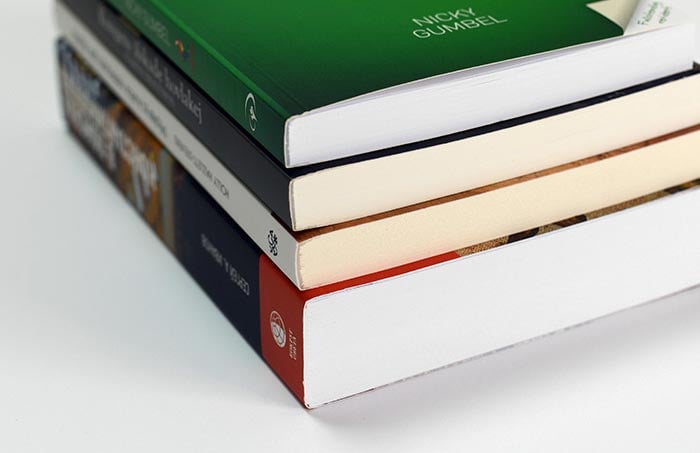

Perfect binding is a bookbinding method commonly used to produce paperback books, magazines, catalogues, and other printed materials. In this binding process, individual sheets of paper are glued together along the spine edge, creating a flat and seamless binding. The cover of the document is usually made from heavier paper or cardstock, which is then glued to the spine and wrapped around the entire book, providing durability and a professional finish. Perfect binding is a popular choice for its clean and modern appearance, making it suitable for a wide range of printed materials.

Other Terms for Perfect Binding

Other terms for perfect binding include:

- Softcover binding

- Paperback binding

- Square spine binding

- Adhesive binding

- Glue binding

These terms are often used interchangeably to refer to the process of binding books or documents using adhesive along the spine edge to create a flat and seamless finish.

What are the Advantages of Perfect Binding?

One of the primary advantages of perfect binding is its professional appearance, making it ideal for creating sleek and polished documents. This binding method allows for the creation of books and other printed materials with a flat spine edge, resembling those found in traditional paperback books. Perfect binding also offers versatility regarding the size and thickness of the documents it can bind, accommodating various paper weights and sheet counts. Additionally, perfect binding is a cost-effective option for producing medium to large print runs, as it can be automated for efficiency. With its clean and modern aesthetic and ability to handle a wide range of materials and quantities, perfect binding is a preferred choice for many printing projects.

What Types of Projects Can Be Perfectly bound?

Perfect binding is a versatile binding method suitable for a wide range of projects across various industries. Some common projects that can be perfect bound include:

- Books: Perfect binding is commonly used for paperback books, including novels, textbooks, manuals, and reference books.

- Magazines and Catalogs: Many magazines and catalogues are perfectly bound due to the professional appearance and durability they provide.

- Brochures and Reports: Perfect binding is often chosen for corporate brochures, annual reports, product catalogues, and marketing materials.

- Journals and Notebooks: Many journals, planners, and notebooks are perfect bound for a sleek and modern look.

- Cookbooks and Recipe Books: Perfect binding is popular for cookbooks and recipe books, allowing them to lay flat for easy use in the kitchen.

- Photo Albums: Perfect binding is suitable for creating photo albums and scrapbooks, providing a clean and professional finish.

- Thesis and Dissertations: Many academic documents, including theses and dissertations, are perfectly bound for a polished appearance.

These are just a few examples of the types of projects that can benefit from perfect binding. With its versatility, durability, and professional appearance, perfect binding is a popular choice for a wide range of printed materials.

Can Any Book be Perfectly Bound?

While perfect binding is suitable for many types of books, not all books are ideal candidates for this binding method. Perfect binding works best for books with a sufficient page count and thickness to create a stable spine. Books with too few pages may not have a thick enough spine to securely hold the adhesive, leading to potential durability issues. Additionally, books with extremely heavy or glossy paper stock may not adhere well with the adhesive used in perfect binding. Therefore, while many books can be perfectly bound, it’s essential to consider factors such as page count, paperweight, and intended use when determining the most suitable binding method for a particular book.

What is the Minimum Page Count for Perfect Binding?

The minimum page count for perfect binding typically depends on the thickness of the paper used and the desired thickness of the spine. Generally, perfect binding is most effective and visually appealing for documents with a minimum of around 40 to 60 pages. This page count ensures that the spine has enough thickness to accommodate the adhesive and maintain durability. However, some factors, such as paper weight and thickness, can influence the minimum page count. It’s essential to consult with a printing professional to determine the optimal page count for your specific project.

What is the Maximum Page Count for Perfect Binding?

The maximum page count for perfect binding depends on several factors, including the thickness of the paper used, the desired thickness of the final product, and the capabilities of the binding equipment. Generally, perfect binding is most effective for documents with a maximum page count of around 300 to 400 pages. Beyond this range, the thickness of the spine may become too bulky, compromising the durability and aesthetics of the finished product. However, some perfect binding machines can handle thicker documents, so it’s essential to consult with a printing professional to determine the maximum page count feasible for your specific project.

Can Perfect Bound Books Have Text Printed on the Spine?

Yes, perfect-bound books can have text printed on the spine. Printing on the spine of a perfectly bound book is common practice, especially for books with titles, author names, or other identifying information. This printing can be done using various methods, including offset printing, digital printing, or even foil stamping for a more decorative effect. Printing on the spine adds visibility and professionalism to the book, making it easier to identify when shelved or displayed. However, it’s essential to consider the thickness of the spine and the size of the text to ensure it is legible and visually appealing.

What Type of Glue is Used in Perfect Binding?

The type of glue used in perfect binding is typically a hot melt adhesive or PUR (polyurethane reactive) adhesive. Hot melt adhesive is a thermoplastic glue that is heated and applied to the spine edge of the book, where it quickly cools and solidifies, bonding the pages together. PUR adhesive, on the other hand, is a reactive adhesive that cures chemically when exposed to moisture in the air. PUR adhesive offers superior flexibility and durability compared to hot melt adhesive, making it ideal for binding books with heavy or coated paper stocks or books that will be subjected to extreme temperature and humidity conditions. Ultimately, the choice of adhesive depends on factors such as the type of paper used, the intended use of the book, and the desired level of durability.

Is it Expensive to Perfectly Bound Books?

The cost of perfect binding books can vary depending on several factors, including the size of the book, the paper quality, the number of pages, and the quantity being produced. Generally, perfect binding is more cost-effective for medium to large print runs compared to short runs due to setup costs. However, perfect binding can still be an affordable option for smaller quantities, especially when compared to other binding methods like hardcover binding. Additionally, advancements in printing technology have made perfect binding more efficient and economical, further reducing costs. Overall, while perfect binding may have upfront setup costs, it can be a cost-effective option for producing professional-looking books in larger quantities.

Best Perfect Binding Machines

Here are some of the best perfect binding machines:

- Boway Perfect Binder BW-JB2

- Boway Perfect Binder BW-920V

- Sysform 50A Professional Perfect Binding Machine

- Sysform 50B Professional Perfect Binding Machine

Are you a business owner seeking to enhance your document organization and presentation capabilities? Consider the efficiency and professionalism that perfect binding machines can bring to your operations. Contact us today to explore a range of comb binding solutions tailored to your specific needs, and elevate the way you present documents in your business.