Tag: binding machines

7 Advantages of Using Comb Binding

In the realm of document binding, choosing the right method is paramount to achieving a professional and organized presentation. Among the various binding options available, comb binding stands out as a versatile and user-friendly solution that offers a multitude of advantages. From its ease of use to the ability to accommodate various document sizes, comb binding is a popular choice for individuals and businesses alike. This article explores the myriad advantages of using comb binding, shedding light on how this simple yet effective method can enhance the functionality and visual appeal of your bound documents.

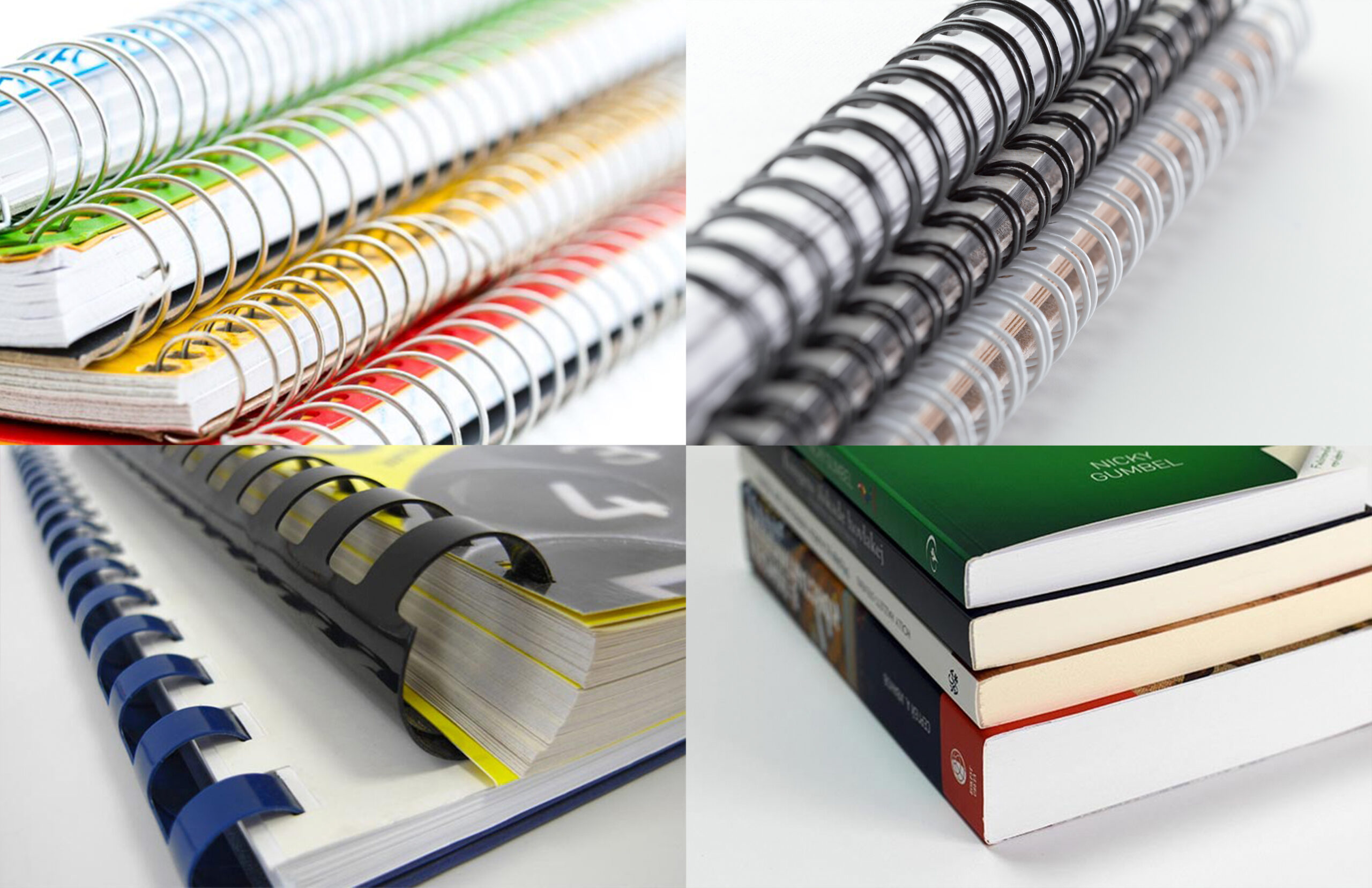

What is Comb Binding?

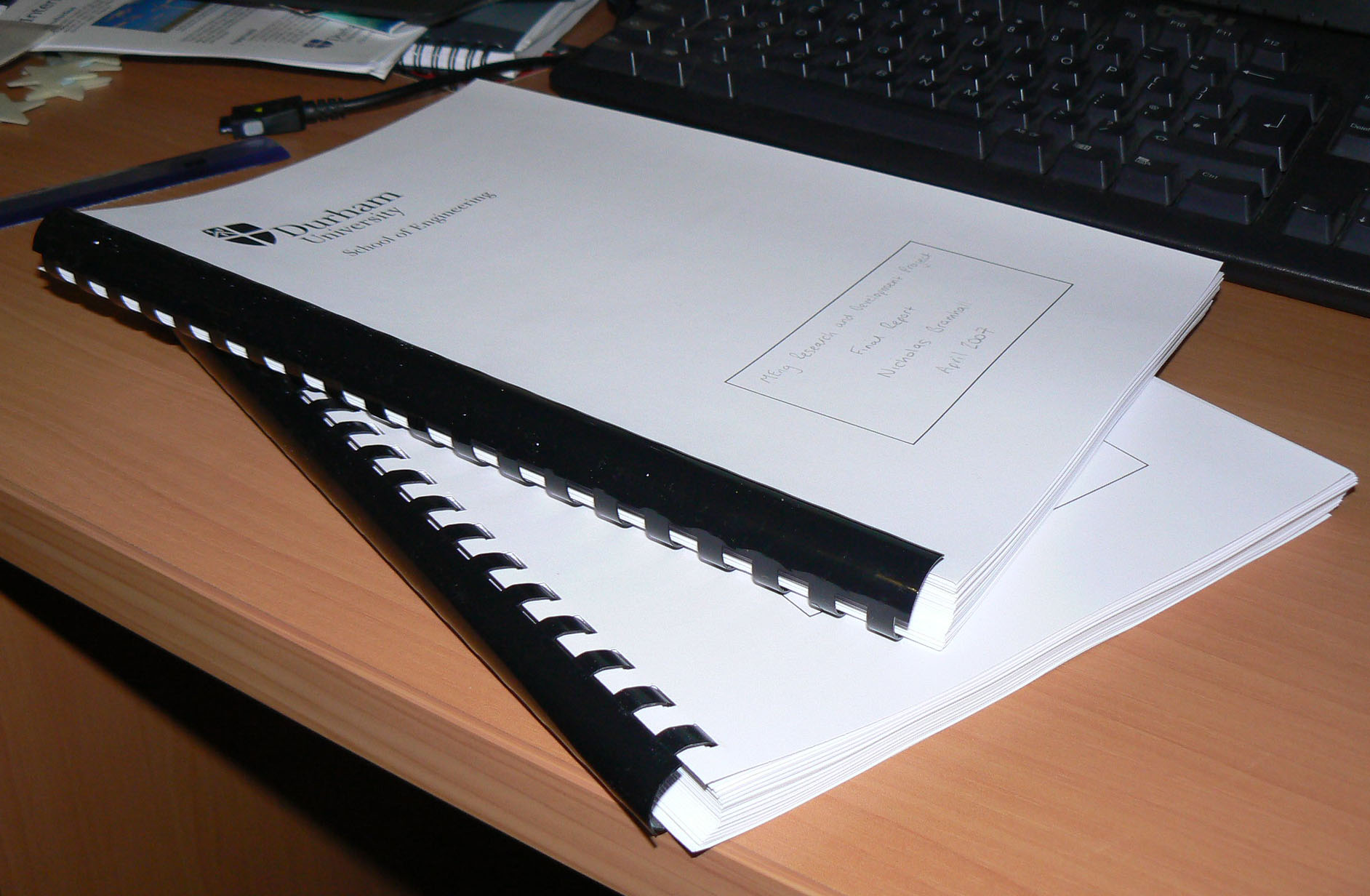

Comb binding is a popular method of document binding that involves using a plastic comb-like spine to secure the pages of a document. This binding technique is widely used for reports, presentations, manuals, and other multi-page documents. The process typically involves punching evenly spaced holes along the edge of the document and then threading a plastic comb through these holes. Once the comb is in place, it is opened, and the document pages are inserted onto the comb’s teeth. Finally, the comb is closed, securing the pages in place. Comb binding is known for its simplicity, affordability, and the ability to easily add or remove pages, making it a versatile choice for various types of documents.

Why is Binding Important?

Binding is a crucial aspect of document organization and presentation, offering a means to assemble and secure loose pages into a cohesive and professional format. Whether for business reports, academic projects, or marketing materials, binding not only enhances the visual appeal of documents but also ensures durability and ease of handling. By securely fastening pages together, binding methods such as spiral binding, comb binding, or thermal binding contribute to a polished and organized presentation, allowing individuals and businesses to convey information effectively. Binding also facilitates easy reference and maintains the integrity of the document over time, making it a fundamental element in creating a lasting and impactful impression.

Advantages of Using Comb Binding

Comb binding offers several advantages, making it a popular choice for various document binding needs:

- Ease of Use: Comb binding is known for its simplicity, making it user-friendly even for individuals without extensive binding experience. The process involves punching holes in the document and threading a plastic comb through the holes, allowing for quick and straightforward assembly.

- Affordability: Comb binding is a cost-effective binding solution, making it accessible for individuals, small businesses, and organizations with budget constraints. The plastic combs used in this method are economical, contributing to overall cost savings.

- Versatility: Comb binding can accommodate a wide range of document sizes, from small booklets to larger reports. This flexibility makes it suitable for various applications, including presentations, training materials, manuals, and reports.

- Easy Editing: One notable advantage of comb binding is the ability to add or remove pages easily. This makes it convenient to update and edit documents without the need for specialized equipment or extensive re-binding.

- Lay-Flat Design: Comb-bound documents lay flat when opened, providing a convenient reading and presentation experience. This feature is particularly useful during meetings, presentations, or when referencing materials, as the pages remain open and easily readable.

- Customization: Plastic combs come in various colours and sizes, allowing users to customize the appearance of their bound documents. This can contribute to branding efforts and enhance the overall aesthetic appeal of the finished product.

- Accessibility: The plastic combs used in comb binding are readily available, making it easy to find replacement combs or additional supplies as needed. This accessibility contributes to the convenience of using comb binding for ongoing document binding requirements.

In summary, comb binding combines simplicity, affordability, and versatility, making it a practical choice for individuals and organizations looking for an efficient and accessible method to bind their documents.

Best Comb Binding Machines

The best comb binding machines combine ease of use, durability, versatility, and safety features to facilitate efficient and secure document binding. Here are some of the best comb binding machines:

- C-12 Comb Binding Machine

A heavy-duty, manual comb binding machine that’s perfect for binding letter-size, A4, A5, or smaller office documents. Its lightweight and portable design makes it an excellent addition to school or small office environments, offering convenience and versatility for document binding needs. This user-friendly machine includes plastic comb-style binder spines, making it an ideal choice for creating professionally-bound documents with ease. - Akiles Duo Mac 321

A heavy-duty, multi-functional, and user-friendly binding machine that offers both money and space-saving benefits. With the ability to perform two different types of binding in one single machine, it provides versatility and efficiency for businesses and individuals looking to streamline their document binding processes while optimizing both cost and workspace. - CombBind C20A Comb Binding Machine

Your go-to solution for creating professional presentations with a high-quality, cost-effective alternative. This user-friendly machine can bind documents up to 2 inches thick (approximately 425 sheets) and can punch up to 20 sheets at once, making it the ideal choice for binding letter-size pages or smaller documents, perfect for school or small office environments.

Are you a business owner seeking to enhance your document organization and presentation capabilities? Consider the efficiency and professionalism that comb binding machines can bring to your operations. Contact us today to explore a range of comb binding solutions tailored to your specific needs, and elevate the way you present documents in your business.