Tag: coil binding

How Medical Offices Benefit with Proper Binding Systems

Medical offices manage large volumes of paperwork daily, including patient records, prescriptions, insurance forms, and treatment reports. Keeping these documents organized is crucial for smooth workflow, patient safety, and compliance with health regulations. A proper binding system helps medical offices secure and manage their documents efficiently. It ensures records remain intact, easy to access, and professionally presented. This article explains what a binding system is, explores the different types of binding systems applicable in medical offices, and highlights the benefits of using them for daily operations.

About Binding System

A binding system is a method or machine that assembles multiple sheets of paper into a single organized document. In medical offices, binding systems make records easy to manage, protect, and store.

Binding systems improve workflow by keeping documents neat and accessible. They reduce errors, prevent pages from getting lost, and ensure patient records remain complete. Binding also supports compliance with health regulations, such as HIPAA, by helping secure sensitive information.

Medical offices can choose from mechanical or thermal binding methods. Mechanical systems, like comb, wire, and spiral binding, allow staff to add or remove pages as needed. Thermal or perfect binding produces durable, professional-looking reports suitable for finalized medical files.

Using a binding system also saves space and time. Instead of loose sheets scattered across desks, medical staff can handle consolidated, organized documents efficiently. Proper binding ensures fast retrieval, which is critical during consultations or emergencies.

Quick Rundown of Different Binding Systems

Medical offices can select from several binding methods based on their specific needs. Each system has advantages for different types of documents, frequency of use, and presentation requirements.

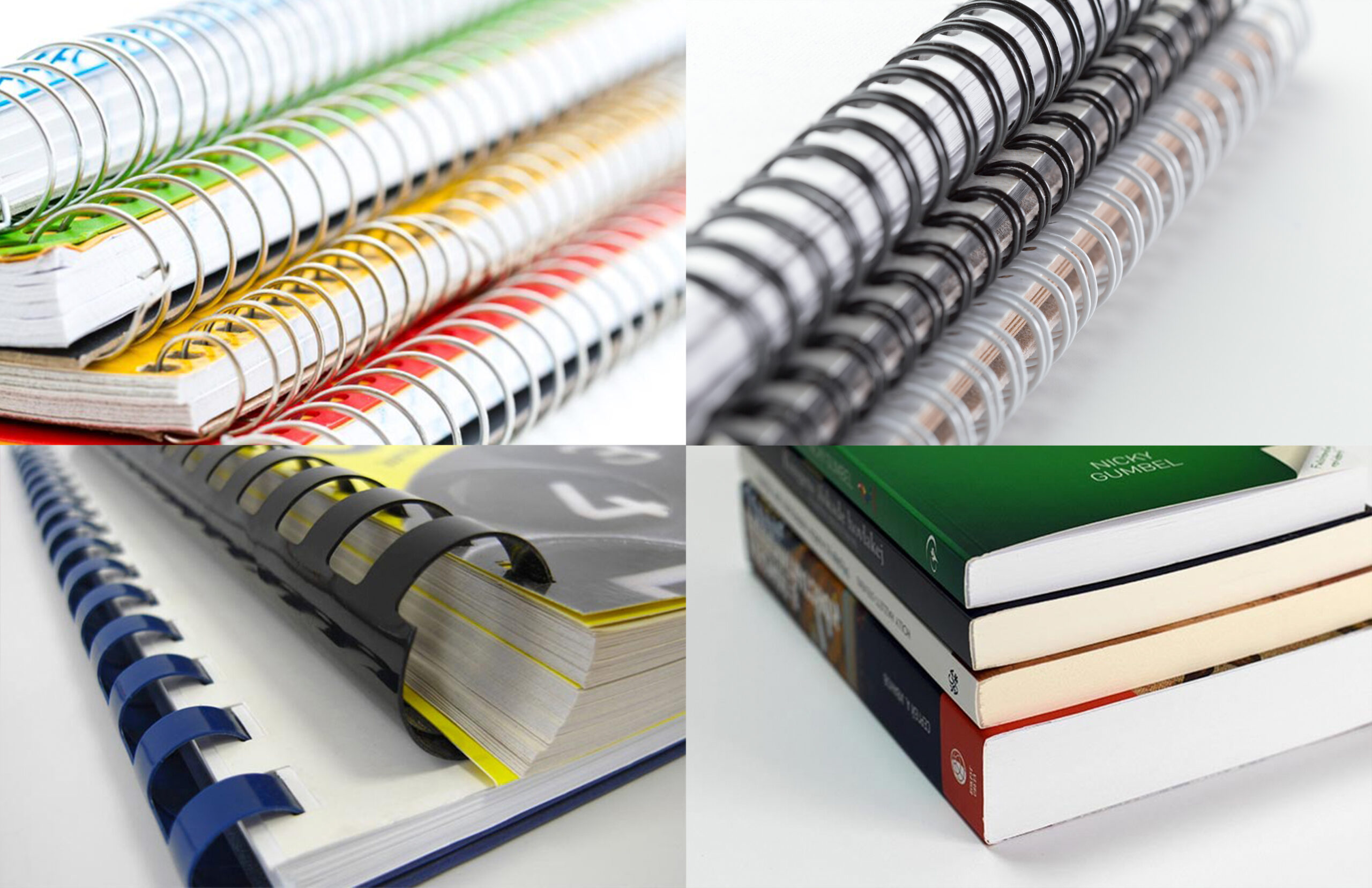

Wire Binding

Wire binding uses a metal wire loop to secure pages. It creates durable, professional documents. Pages rotate 360 degrees, making it easy to review and annotate. Ideal for medical reference guides and training manuals.

Comb Binding

Comb binding uses a plastic comb inserted into punched holes. Staff can easily add or remove pages. Best for forms, schedules, or patient intake documents that require frequent updates.

Coil or Spiral Binding

Coil or spiral binding uses a continuous plastic coil through punched holes. It is flexible and durable. Documents lie flat, making it suitable for logs, notes, or instructional manuals.

Thermal Binding

Thermal binding uses heat-activated adhesive applied to pre-glued covers. Pages are permanently bound. Ideal for finalized reports, policy manuals, and patient handbooks.

Perfect Binding

Perfect binding uses glue along the spine to hold pages together. It creates a professional book-like finish. Suitable for thick reports, annual records, or medical publications.

Benefits of Proper Binding Systems in Medical Offices

Using binding systems in a medical office provides multiple benefits, improving organization, efficiency, and professionalism.

1. Organized Records

Binding keeps documents neatly together and prevents loose pages. Patient files, treatment histories, and insurance claims stay complete and easy to reference.

2. Quick Retrieval

Bound documents are easier to find and sort. Staff can quickly access information during consultations, reducing waiting times and improving patient experience.

3. Professional Appearance

Binding gives files a polished, clean look. Reports, manuals, and patient guides look professional, reinforcing credibility and trust.

4. Improved Document Security

Binding systems secure sensitive information. Pages are less likely to be lost, misplaced, or damaged. Thermal or perfect binding adds an extra layer of tamper-resistance.

5. Durability and Longevity

Bound documents withstand frequent handling better than loose sheets. Wire, spiral, and thermal binding methods ensure long-lasting durability for critical medical records.

6. Easy Updates and Editing

Mechanical binding systems allow staff to add or remove pages as needed. This flexibility is ideal for forms or protocols that change over time.

7. Space Efficiency

Bound files are easier to store and stack. Shelving space is optimized, and filing cabinets remain organized.

8. Compliance Support

Properly bound files help offices maintain organized records in line with HIPAA and other healthcare regulations. Accurate record-keeping reduces legal and operational risks.

Binding Consumables in Medical Offices

Binding systems rely on printing consumables such as covers, wires, coils, combs, adhesives, and labels. These materials are essential for smooth operations and professional results.

- Covers: Provide protection and improve presentation. Options include clear plastic, cardstock, and laminated finishes.

- Wires and Coils: Required for wire or spiral binding, available in different sizes and colors.

- Combs: Plastic combs for comb binding, reusable and adjustable.

- Adhesives: For thermal and perfect binding, ensure strong, lasting bonds.

- Labels: For indexing, patient identification, or document categorization.

Keeping consumables in stock ensures uninterrupted operations. Medical offices can maintain high-quality results without delays.

Running Out of Consumables

Running out of printing consumables can disrupt operations in medical offices. Delays in binding reports, patient records, or manuals can affect workflow and patient care.

- Staff may spend extra time manually organizing loose documents.

- Documents may appear unprofessional or be less durable.

- Errors and misplaced pages can increase, creating compliance risks.

- Urgent patient files may become difficult to retrieve quickly.

To avoid these problems, offices should track consumable levels and reorder before running out. Maintaining a buffer stock prevents downtime and ensures continuous high-quality document management.

Best Practices for Using Binding Systems in Medical Offices

Medical offices can maximize benefits by following these best practices:

- Train staff to use binding machines safely and efficiently.

- Select binding methods suitable for document type and usage frequency.

- Store consumables properly in cool, dry areas to maintain quality.

- Inspect bound files for alignment, completeness, and durability.

- Maintain machines regularly to prevent breakdowns and downtime.

Following these steps ensures consistent, professional, and secure document handling across the office.

Proper binding systems are crucial for medical offices to manage records efficiently, professionally, and securely. Choosing the right binding method improves workflow, saves time, and protects sensitive patient information. By maintaining consumables and machines, offices can prevent disruptions and ensure high-quality output. From wire and comb to thermal and perfect binding, each system offers unique advantages for different document types. Medical offices that adopt binding systems experience better organization, compliance, and patient service. Investing in proper binding solutions is a small step that delivers long-term operational benefits, enhances professionalism, and supports patient trust.

Are you a business owner in search of reliable coil-binding machines to streamline your document-binding needs? Look no further. Discover the perfect coil binding solution for your organization today by exploring our range of top-quality machines. Contact us now to find the ideal coil binding machine that meets your specific requirements and witness the difference it can make for your business.