Tag: roland dga

Printing 101: What is Flatbed Ink Jet Printing?

When it comes to printing, the ability to create expansive prints on a wide range of materials has brought about a significant transformation in the industry. Central to this transformation lies flatbed digital printing. It stands as a revolutionary approach that has transformed the way we produce high-quality graphics and imagery on various surfaces. This innovative technique has redefined the possibilities of printing, offering exceptional versatility and precision. In this article, we delve into the intricate details of flatbed inkjet printing, exploring what it is, how it works, and its profound impact on industries ranging from signage and graphics to custom product decoration. Join us as we embark on a journey through the world of flatbed inkjet printing, where imagination knows no bounds.

What is Flatbed Ink Jet Printing?

Flatbed inkjet printing is a cutting-edge printing technology that enables the direct application of ink onto flat or nearly flat surfaces. Unlike traditional printing methods that rely on printing onto flexible substrates and then transferring the image, flatbed inkjet printers print directly onto the desired type of substrates, creating high-resolution graphics and images.

Flatbed inkjet printing is known for its versatility, as it can be used in various industries and applications, including outdoor signage, graphics, packaging, architectural renderings, and art reproduction. The ability to print on rigid and non-traditional materials makes it a go-to choice for those seeking high-quality, customized prints on a wide array of surfaces. This technology has opened up new horizons in the printing world, enabling large-format printing businesses and individuals to transform their creative visions into reality with exceptional precision and vibrant colour output.

How Flatbed Inkjet Printers Work

Flatbed printers employ vacuum tables to secure rigid or flexible sheets in position while an industrial-grade printhead jets the ink. These tables serve the dual purpose of stabilizing the substrates, ensuring they remain flat to maintain a consistent gap between the printheads and the material. Certain vacuum tables feature multiple print zones, enabling the system to print on various sizes of materials simultaneously.

Some flatbed printers have the capability to vary the size of ink droplets, resulting in high-quality images that exhibit intricate details and seamless transitions between shades. These printers can precisely place ink droplets, even over images previously printed using other printing methods. Most flatbed printers use “scanning” printheads that traverse back and forth across the width of the printed sheet.

Large Format Printing Products That Use Flatbed Ink Jet Printer

Flatbed inkjet printers are versatile tools that can produce a wide range of large-format printing products. Some of the common products and applications that use flatbed inkjet printing technology include:

- Signage: Flatbed inkjet printers are ideal for creating various types of signs, including outdoor billboards, indoor posters, real estate signs, and trade show displays. They can print on rigid materials such as foam board, PVC, and acrylic.

- Point-of-Purchase (POP) Displays: Flatbed printers are commonly used to produce eye-catching POP displays for retail environments. These displays can be made from materials like corrugated cardboard, foamcore, or expanded PVC.

- Custom Packaging: Flatbed inkjet printers are used to create customized packaging solutions, including branded boxes, cartons, and labels. This is particularly valuable for businesses looking to enhance their product presentation.

- Personalized Products: Customization is a growing trend, and flatbed inkjet printing enables the production of personalized items like smartphone cases, laptop covers, promotional products, and more.

- Architectural and Interior Design: Flatbed printing can be used to produce large-format architectural plans, interior décor elements, and custom tiles for interior design projects.

- Event Graphics: For events and trade shows, flatbed printers are used to create graphics for booths, backdrops, and promotional materials.

Best Flatbed Ink Jet Printer in 2023

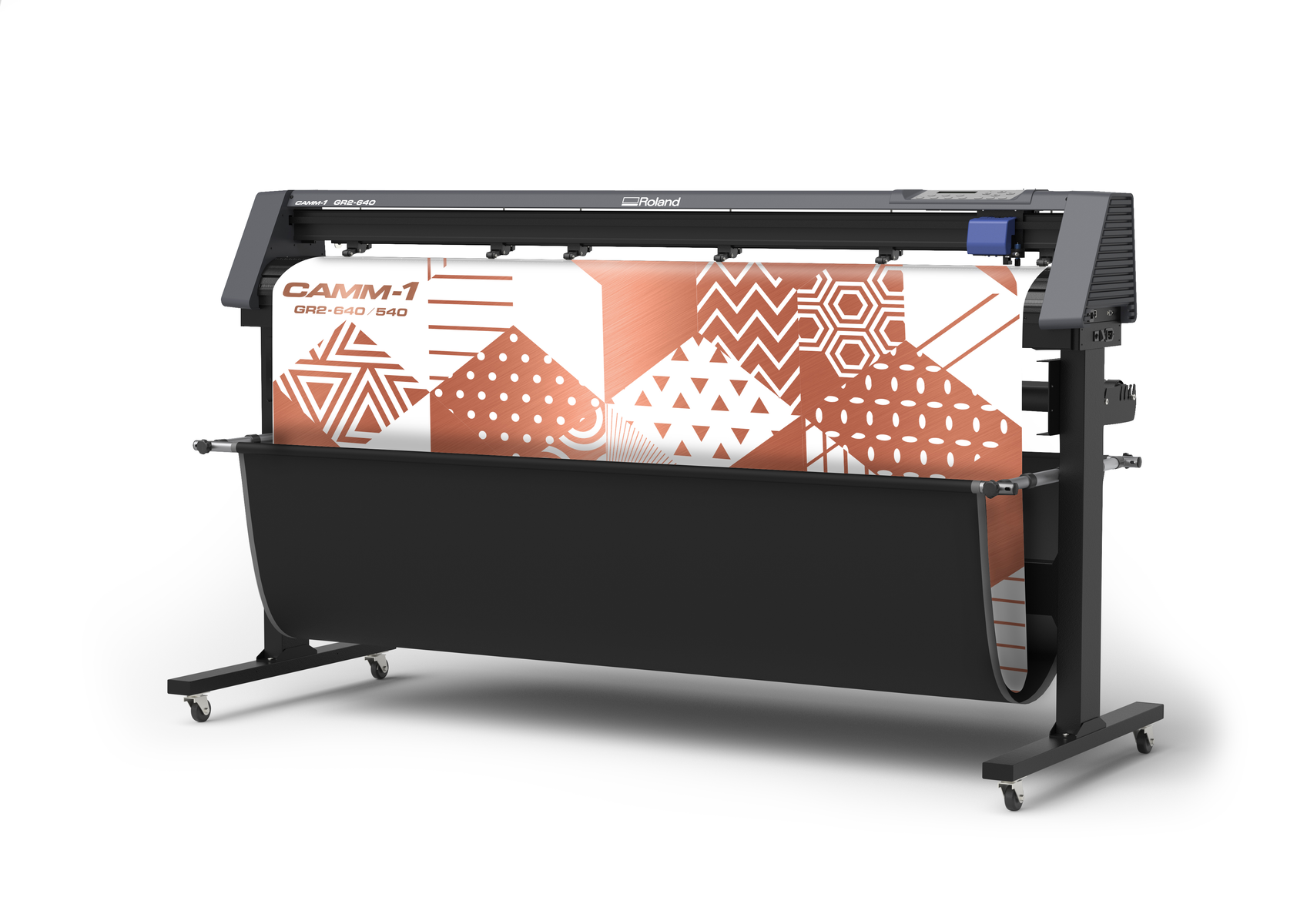

Here are some of the best flatbed inkjet printers by Roland DG Solutions:

- Roland LEF-12i Desktop UV-Flatbed-Printer

- VersaUV LEF2 200

- VersaUV LEF2-300 Flatbed Printer

- VersaUV LEF2-300D

- VersaUV LEC2 S Series Flatbed and Belt Drive Printers

- VersaObject CO Series Flatbed and Hybrid Printers

- Roland IU 1000F UV-LED

Are There Other Types of Wide-Format Printing?

Yes, wide-format printing encompasses a variety of technologies and methods beyond flatbed inkjet printing. Some of the other common types of wide-format printing include:

- Roll-to-Roll Inkjet Printing: In this method, large rolls of printing material, such as paper, vinyl, or fabric, are fed through the printer. Roll-to-roll printers are widely used for applications like banners, posters, vehicle wraps, and fabric printing.

- Dye Sublimation Printing: Dye sublimation printing is used primarily for textiles and fabrics. It involves printing onto a special transfer paper and then using heat to transfer the design onto the fabric. This method is popular for creating custom apparel and soft signage.

- Solvent Printing: Solvent inkjet printing is commonly used for outdoor graphics, vehicle wraps, and large-scale signage. It employs solvent-based inks that are weather-resistant and adhere well to various substrates.

- Latex Printing: Latex inkjet printing uses water-based latex inks, which are more environmentally friendly compared to solvent inks. Latex printers can produce high-quality graphics suitable for various applications, including indoor and outdoor signage.

- UV Printing: UV inkjet printing involves curing ink with ultraviolet (UV) light. This technology is used for printing on both flexible and rigid materials, such as glass, acrylic, and metal. UV prints are known for their durability and resistance to fading.

- Dye-Sublimation Transfer Printing: This method is often used for textile and fabric printing, including clothing, home decor, and soft signage. The design is printed onto a transfer paper, and then heat and pressure are applied to transfer the ink onto the fabric.

When it comes to starting a wide-format printing business, flatbed inkjet printing has emerged as a game-changer, offering boundless creative possibilities and unmatched versatility. Whether you’re in the business of producing eye-catching signage, custom decor, or personalized promotional products, flatbed inkjet printers have become indispensable tools for realizing your vision. This innovative printing method has not only expanded the horizons of large-format printing but has also redefined what’s achievable in terms of precision, quality, and artistic expression.

If you’re a business owner seeking to unlock the full potential of your printing projects, it’s time to explore the world of flatbed inkjet printing. Whether you’re in signage, interior design, or the world of custom branding, we’re here to help you harness the power of flatbed inkjet printing. Contact us today to discover the perfect flatbed inkjet printing solution for your business and elevate your printing game to new heights.