Tag: printing business tips

Tips When Creating and Printing Business Cards

Creating a memorable and effective business card is crucial in today’s competitive business environment. A well-designed business card not only provides essential contact information but also reflects your brand and professionalism. This is especially important for professionals across various industries, including marketing, sales, creative arts, and entrepreneurship, where first impressions can significantly impact business opportunities. This article will cover essential tips for designing and printing business cards, ensuring they leave a lasting impression. From choosing the right design elements and materials to understanding the importance of colour consistency and special finishes, we will guide you through creating business cards that stand out and effectively represent your brand.

Tips To Remember When Creating a Business Cards

Business cards remain an essential tool for networking and professional introductions. Their design and print quality can leave a lasting impression, making it crucial to get them right. Utilizing large format printers for business card production can offer unique advantages in terms of precision and quality. Here are some tips for creating and printing business cards using large format printers.

1. Understand the Advantages of Large Format Printers

Large format printers are typically associated with posters, banners, and other oversized prints, but they can also be used effectively for smaller items like business cards. The key benefits include:

- Precision: Large format printers provide high-resolution outputs, ensuring that small text and intricate designs are clear and sharp.

- Quality Control: They often allow for greater control over colour calibration and print consistency, which is crucial for maintaining your brand’s colour integrity.

- Versatility: These printers can handle a variety of paper stocks and finishes, giving you more options for customizing your business cards.

Here are some of the best large format printer in 2024:

- TrueVIS VG3 Series Printers/Cutters

The TrueVIS VG3-540 / VG3-640 Series Printers Cutters combine cutting-edge printing technology with precise cutting capabilities, delivering outstanding graphics and designs with vivid colours and exceptional precision. - Roland VersaSTUDIO BN2 Series Desktop Printer/Cutters

Offers a compact yet powerful solution for high-quality printing and precise cutting, making it perfect for small businesses and creative endeavours. Its versatile capabilities and user-friendly design make it an ideal choice for producing a variety of graphics and designs with exceptional detail and colour. - TrueVIS AP-640

Blending the rapid drying and eco-friendly attributes of resin printing with the remarkable colour rendition, user-friendly operation, and dependable performance synonymous with TrueVIS Series printers - Roland Model LG-640 / LG-540 / LG-300

Designed to deliver high-quality UV printing on a variety of rigid and flexible substrates, allowing businesses to produce stunning graphics, signage, and promotional materials. With their advanced UV ink technology and precise printing capabilities, these printers offer exceptional colour accuracy, durability, and versatility, making them ideal for a wide range of applications in the graphics and printing industry.

2. Design with Clarity and Simplicity

A business card should convey essential information quickly and clearly. Here are some design tips:

- Prioritize Information: Include only essential details such as name, title, company name, phone number, email address, and website.

- Readability: Use easy-to-read fonts and avoid overly decorative typefaces. Ensure the text is large enough to be legible without straining the eyes.

- White Space: Don’t overcrowd your card. Adequate white space ensures the design looks clean and professional.

- Logo Placement: Place your logo prominently but ensure it doesn’t overshadow the contact information.

3. Utilize High-Resolution Images and Graphics

For your business card to look professional, all images and graphics must be high resolution:

- 300 DPI (Dots Per Inch): This is the minimum resolution for images and graphics to appear sharp in print.

- Vector Graphics: Use vector formats for logos and icons to ensure they remain crisp at any size.

4. Color and Branding Consistency

Maintaining brand consistency across all marketing materials is vital:

- CMYK Color Mode: Design your cards in CMYK mode, the colour profile used in printing, to ensure colours print accurately.

- Colour Calibration: Regularly calibrate your monitor and printer to maintain colour consistency between your digital design and printed cards.

- Brand Colors: Use your brand’s official colours to ensure uniformity across all your business materials.

5. Choose the Right Paper Stock

The choice of paper stock can significantly impact the look and feel of your business cards:

- Thickness: Thicker cardstock (14pt or 16pt) feels more substantial and professional.

- Finish: Decide between glossy, matte, or uncoated finishes based on the impression you want to leave. Glossy finishes offer vibrant colours, matte finishes provide a sophisticated look, and uncoated finishes offer a natural feel.

- Texture: Textured stocks like linen or recycled paper can add a unique touch.

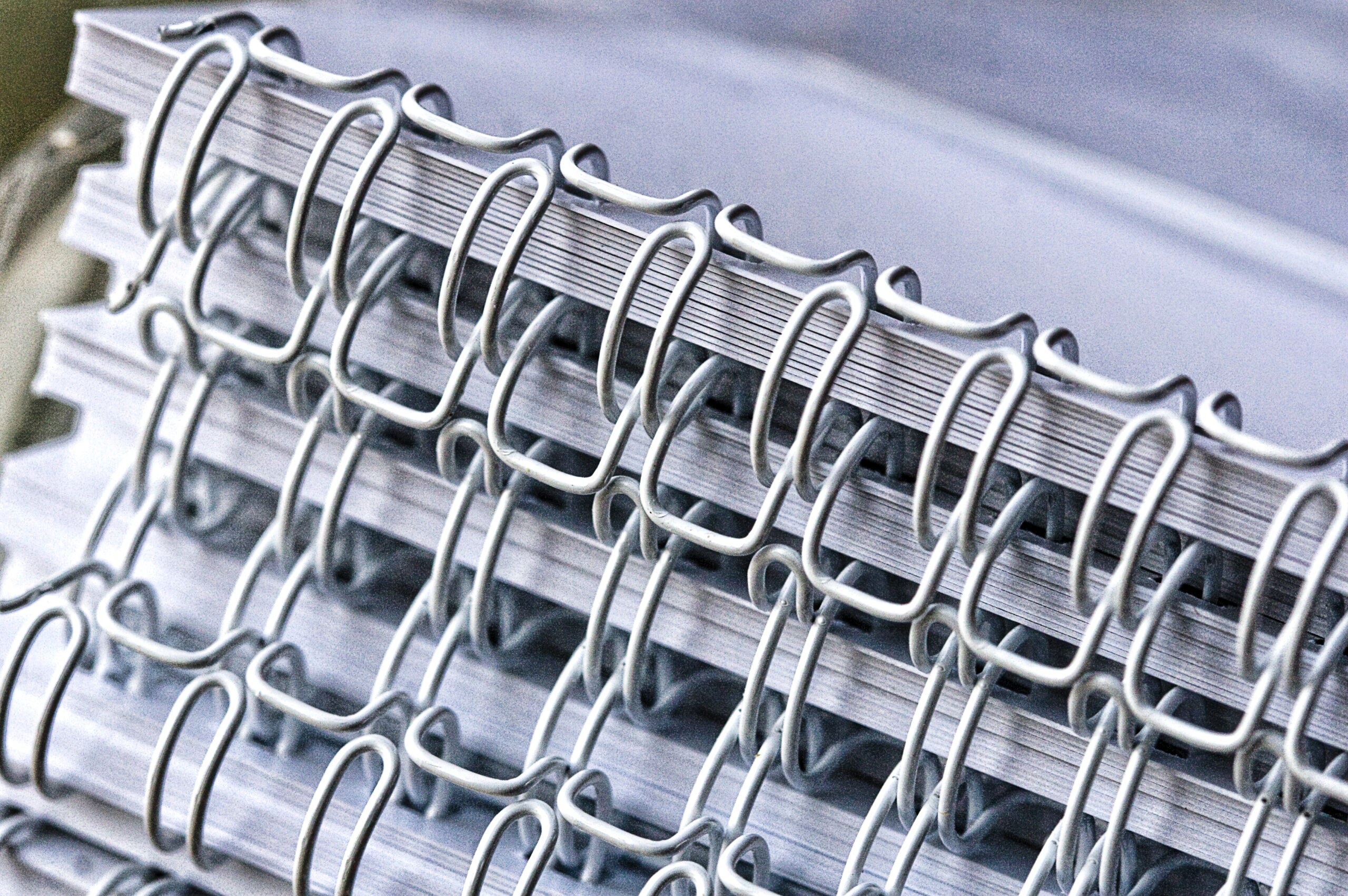

6. Incorporate Special Finishes

Special finishes can enhance the appeal of your business cards:

- Spot UV Coating: Highlights specific areas with a glossy finish, making them stand out.

- Foil Stamping: Adds a metallic finish to certain elements, like logos or text, for a premium look.Embossing/Debossing: Creates a raised or recessed effect on text or images, adding a tactile dimension.

7. Prepare Your Files Correctly

Proper file preparation is crucial for high-quality prints:

- Bleed Area: Include a 1/8 inch bleed area around your design to ensure no white edges appear after cutting.Safe Zone: Keep all critical text and images within the safe zone, at least 1/8 inch from the edge.

- File Format: Save your design in a high-resolution PDF with embedded fonts and images.

8. Test Print and Proofread

Before printing the full batch, always:

- Print a Test Copy: Check for colour accuracy, text legibility, and overall design appearance.

- Proofread: Carefully check for typos and errors. It’s often helpful to have another person review the card as well.

9. Use Templates

Many large format printers offer templates to ensure your design fits their specifications:

- Consistency: Templates help maintain consistency and ensure your design meets the printer’s requirements.

- Ease of Use: They simplify the design process, saving time and reducing errors.

10. Order a Sample Batch

If you’re using a new printer or trying a new design, order a small batch first:

- Quality Check: Assess the quality of the print and paper stock.

- Design Evaluation: Ensure the design looks as expected in print form.

11. Consider Eco-Friendly Options

For an environmentally friendly approach:

- Recycled Paper: Choose paper stocks made from recycled materials.

- Eco-Friendly Inks: Opt for printers that use soy or vegetable-based inks.

Creating and printing business cards using large format printers can yield high-quality, professional results. By focusing on clarity, maintaining brand consistency, choosing the right materials, and properly preparing your files, you can ensure that your business cards make a lasting and positive impression. Always test print, proofread meticulously, and consider special finishes to elevate the design. With these tips, you can leverage the capabilities of large format printers to produce standout business cards that effectively represent your brand.

Are you in the process of starting or expanding your large format printing business and in need of expert guidance on purchasing the right printing machine? Look no further! Our team of industry experts is here to provide you with valuable insights and expert opinions to help you make the best decision for your business. With a deep understanding of the large format printing industry, we can assist you in selecting the ideal printing machine that meets your specific requirements and budget. Contact us today for a personalized consultation and let us help you make the right investment for your business’s growth and prosperity.