Category: Guide

Tips When Buying a Coil Binding Machine

In today’s rapidly evolving printing industry, the demand for efficient and versatile binding solutions is more pronounced than ever before. From small businesses and educational institutions to commercial printing enterprises, the need for a proper coil binding machine has become indispensable. In this article, we delve into the critical importance of selecting the best coil binder to meet your specific requirements and ensure seamless document finishing. Whether you’re a print shop owner, an office manager, or a student preparing presentations, understanding the key factors to consider when purchasing a coil binding machine can make all the difference in streamlining your workflow and achieving professional results. From exploring the various types of coil binding machines available to provide invaluable tips and insights on selecting the right model for your needs, this article serves as a comprehensive guide for anyone seeking to enhance their binding capabilities in today’s competitive printing landscape.

What is a Coil Binding Machine and How It Works

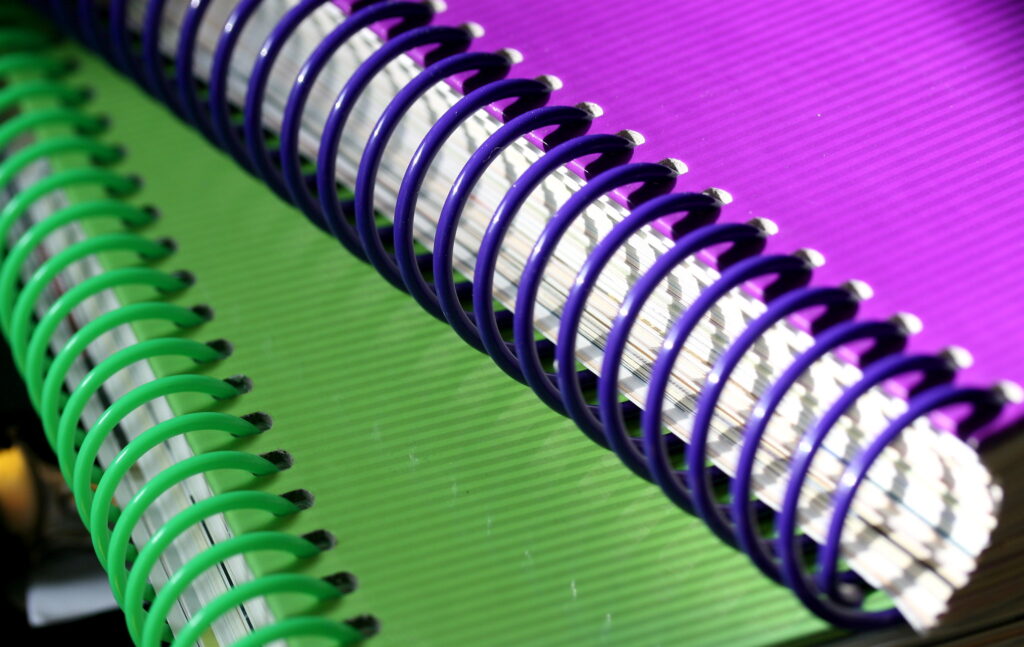

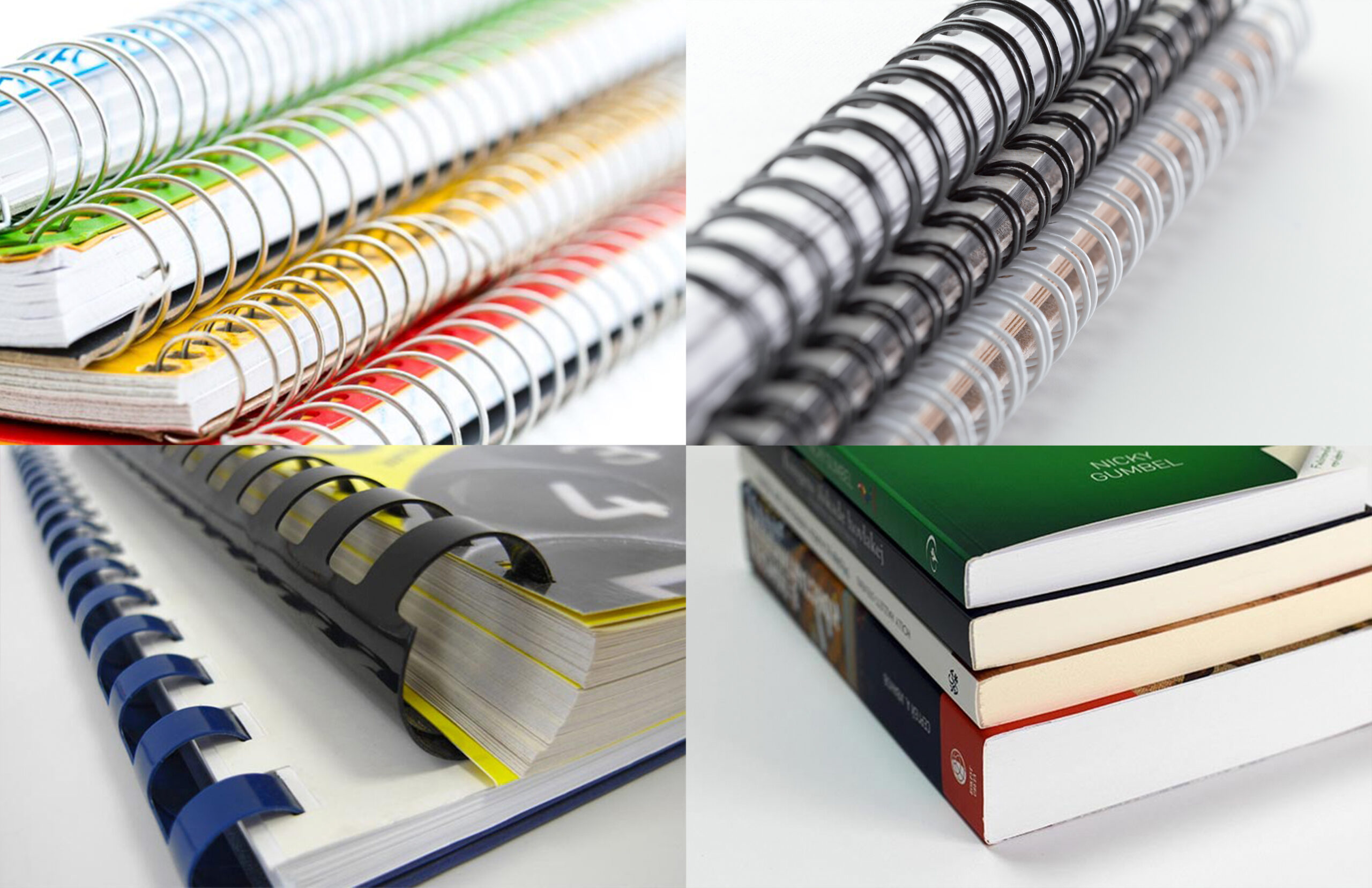

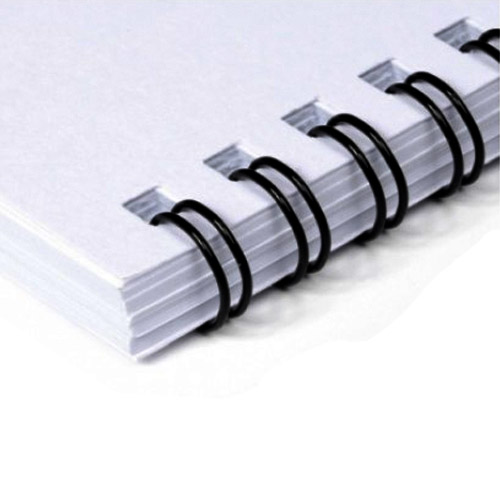

A coil binding machine is used for binding documents, reports, presentations, and other printed materials. It utilizes plastic coils, also known as spiral coils or coil bindings, to bind the pages together securely. The coil binding process involves punching evenly spaced holes along the edge of the document using a punching mechanism, then threading the coil through the holes using a coil inserter and finally crimping the ends of the coil to prevent it from unravelling. Coil binding machines come in various sizes and capacities, ranging from manual, desktop models suitable for small offices and personal use to electric or automated machines designed for high-volume commercial printing operations. They offer flexibility, durability, and a professional appearance, making them a popular choice for businesses, schools, and organizations seeking reliable document-binding solutions.

Tips to Remember Before Buying a Coil Binding Machine

Before purchasing a coil binding machine, there are several important factors to consider to ensure you select the right one for your needs. Here are some tips to keep in mind:

- Capacity and Volume: Assess your binding needs in terms of the volume of documents you plan to bind regularly. Consider the machine’s punching and binding capacity to ensure it can handle your workload efficiently without causing delays or strain.

- Coil Size Compatibility: Determine the range of coil sizes you anticipate using for your documents. Ensure that the coil binding machine you choose is compatible with the coil diameters you plan to utilize to accommodate different document thicknesses.

- Punching Patterns: Evaluate the punching patterns offered by the machine to ensure they match your document size and layout requirements. Some machines offer adjustable punching dies or interchangeable die sets to accommodate various paper sizes and hole patterns.

- Ease of Use: Look for a coil binding machine with user-friendly features and intuitive controls to simplify the binding process and minimize training time for operators. Consider factors such as ergonomic design, automatic features, and clear instructions to ensure smooth operation.

- Durability and Build Quality: Invest in a coil binding machine constructed from durable materials and built to withstand heavy-duty use. Choose reputable brands known for their reliability and longevity to minimize the risk of breakdowns and ensure long-term performance.

- Additional Features: Consider any additional features or accessories that may enhance the functionality of the coil binding machine, such as built-in coil crimpers, electric coil inserters, or adjustable margin settings. Evaluate whether these features align with your specific binding needs and workflow preferences.

- Budget: Establish a budget for your coil binding machine purchase and compare prices across different brands and models to find the best value for your investment. Balance cost considerations with the machine’s features, capabilities, and long-term reliability to make an informed decision.

By keeping these tips in mind and thoroughly evaluating your binding requirements, you can confidently select the right coil binding machine to meet your needs and streamline your document binding process.

Don’t forget to read our most Frequently Asked Questions about coil binding. This can help you gain more insights before buying your coil binding machine.

Why Proper Binding is Important

Proper binding is crucial for several reasons across various industries and contexts.

Firstly, it enhances the durability and longevity of documents, ensuring that pages remain securely bound together even with frequent handling or transportation. This is especially important for important reports, presentations, manuals, and other documents that need to withstand regular use.

Additionally, proper binding provides a professional appearance, making documents more visually appealing and easier to read, which can significantly impact the perception of the content and the credibility of the sender or organization.

Moreover, binding helps organize and streamline information, making it easier for readers to navigate through the document and locate specific sections or chapters. Whether for internal use within a company, distribution to clients or customers, or submission for academic or legal purposes, proper binding adds a level of professionalism and polish to documents, ultimately contributing to clearer communication and effective information dissemination.

Best Coil Binding Machines in 2024

The best coil binding machines combine ease of use, durability, versatility, and safety features to facilitate efficient and secure document binding. Here are some of the best coil binding machines:

- Akiles Duo Mac 321

A versatile and user-friendly coil binding machine, designed to streamline the binding process for businesses and organizations. With its efficient electric punching and binding capabilities, it empowers users to create professionally bound documents with ease and precision. - CoilBind S25A Spiral Coil Binding Machine

A versatile and user-friendly solution for schools and small offices. It boasts a robust punch capacity of up to 20 sheets (20# paper) and features a full handlebar that accommodates left-handed, right-handed, or two-handed operations, ensuring ease of use. Its lightweight and portable design makes it an excellent addition to any workspace, providing efficient coil binding capabilities for a variety of document binding needs. - SUPU PC360E Electric Coil Binding Machine 14″

A high-performance binding solution designed for businesses and print shops. With its electric punching and binding capabilities, it streamlines the coil binding process, allowing for the efficient production of professional-quality documents and presentations.

Remember, investing in the right coil binding machine is essential for businesses, organizations, and individuals seeking to enhance their document-binding capabilities. By considering factors such as capacity and volume, coil size compatibility, punching patterns, ease of use, durability, additional features, and budget, you can make an informed decision that aligns with your specific needs and preferences. Whether you’re a small office, a print shop, or an educational institution, selecting the appropriate coil binding machine can streamline your workflow, improve efficiency, and elevate the professional appearance of your documents. With careful consideration and thorough research, you can confidently choose a coil binding machine that meets your requirements and helps you achieve outstanding results in your binding projects.

Are you a business owner in search of reliable coil-binding machines to streamline your document-binding needs? Look no further. Discover the perfect coil binding solution for your organization today by exploring our range of top-quality machines. Contact us now to find the ideal coil binding machine that meets your specific requirements and witness the difference it can make for your business.